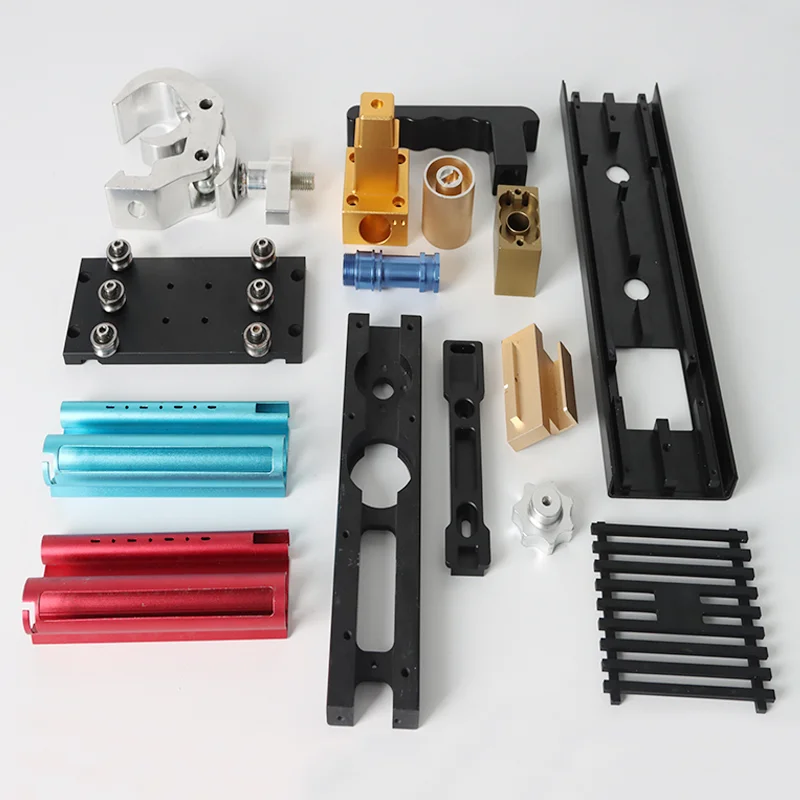

In today’s fast-paced world of making things, being super accurate and unique matters a lot. At XiHui Aluminium, we focus on using awesome CNC processing to create custom aluminum alloy parts. These parts meet the tough needs of industries like airplanes, cars, electronics, and medical tools. This blog dives into what CNC processing is, why customizing aluminum alloys is great, where these parts are used, and what to think about when choosing this method. Let’s explore why high-precision CNC processing is the best choice for aluminum alloy customization.

The Fundamentals of High-precision CNC Processing

High-precision CNC (Computer Numerical Control) processing is a big deal for building stuff. It uses machines run by computers to shape aluminum alloys with amazing accuracy. This makes sure every piece fits exact plans. Plus, it helps makers build detailed, reliable parts for specific jobs. That’s why it’s a top tool for industries that need high quality.

Key Features of CNC Processing Technology

CNC processing stands out because of its cool features. Here’s the rundown:

- Automatic Action: Computer-guided tools move perfectly. This cuts down mistakes and keeps things steady.

- Multi-Angle Cuts: 5-axis CNC machines tackle tricky shapes. They create complex designs in one go.

- Works for Many Needs: CNC systems handle different aluminum alloys. They fit all kinds of projects.

- Fast Work: Automatic steps make things quicker. You save time without losing quality.

- Always the Same: Every part comes out identical. This is super important for industries that need consistency.

Advantages of Precision in Aluminum Alloy Fabrication

Being super precise in CNC processing brings real perks for aluminum alloy parts:

- Perfect Fits: Parts are made to tiny measurements. They work smoothly in any setup.

- Great Quality: Exact cuts mean fewer errors. You get strong, high-performing pieces every time.

- Fancy Shapes: Precision allows for cool, detailed designs. Old methods can’t match this.

- Less Waste: Accurate cuts use less material. This saves aluminum and keeps costs down.

Benefits of Customizing Aluminum Alloys with CNC Processing

Customizing aluminum alloys with CNC processing offers awesome benefits. It creates parts that are tougher, more accurate, and budget-friendly. This method delivers solutions that improve products across many industries.

Enhanced Durability and Strength in Customized Components

Customized aluminum alloy parts are built to last. By choosing the right alloy and cutting methods, we ensure:

- Strong but Light: Alloys like 7075 are super tough without being heavy. They’re great for hard jobs.

- No Rust: Alloys like 6061 hold up in rough places. This makes parts last longer.

- Special Treatments: Steps like anodizing make parts stronger. They protect against wear and tear.

Achieving Complex Geometries with Precision Techniques

CNC processing is awesome for making fancy designs that fit specific needs. Here’s how it helps:

- Cool Designs: 5-axis cutting creates complex shapes, like curves or inner channels, with ease.

- Steady Results: Precise methods ensure every piece matches the plan. This is key for setups with lots of parts.

- Flexible Choices: Customization allows unique features, like light frames or user-friendly designs.

Our CNC metal machining services are designed to deliver these detailed, high-quality pieces with great accuracy.

Cost-efficiency in Large-scale and Small-scale Production

CNC processing saves money for both small and big projects:

- Test Runs: Small batches let you try new ideas. You don’t need big setup costs, which is great for startups.

- Big Orders: Automatic systems handle large runs efficiently. This lowers the cost per piece.

- Less Material Waste: Precise cuts reduce extra material use. This saves money on aluminum alloys.

Applications of CNC Processing Aluminum Alloys

Customized aluminum alloy parts, made with high-precision CNC processing, are super important in many industries. Their flexibility and performance make them key for building reliable, new products.

Aerospace and Automotive Industries

In airplanes and cars, aluminum alloys are loved for being light and strong. Here’s where they shine:

- Airplanes: Parts for frames, engines, and landing gear use aluminum’s strength and light weight.

- Cars: Engine pieces, body frames, and custom fittings rely on precise aluminum for great performance.

Our custom CNC machining services provide tailored solutions for these high-demand fields.

Electronics and Consumer Goods Manufacturing

Aluminum alloys are a big part of gadgets and everyday items. They look good and work well:

- Gadgets: Heat sinks, casings, and connectors use aluminum for cooling and sleek designs.

- Everyday Items: Light frames for wearables, laptops, and appliances benefit from custom aluminum parts.

Medical Equipment and Specialized Tools

The medical field relies on aluminum alloys for their safety and precision. Here’s a quick look:

| Use | Aluminum Part Use |

| Surgical Tools | Light handles and frames for exact instruments |

| Diagnostic Machines | Casings for big imaging systems like MRI scanners |

| Special Tools | Custom parts for dental tools or prosthetics |

These examples show how vital CNC-processed aluminum is for safe, reliable medical gear.

Factors to Consider When Opting for Aluminum Alloy Customization

Choosing the right way to customize aluminum alloys takes careful thought. Here are key things to keep in mind to make your project a success.

Material Selection for Specific Applications

Picking the right aluminum alloy is super important for performance. Common choices include:

- 6061 Aluminum: Tough and rust-proof. It’s great for structural pieces like frames.

- 7075 Aluminum: Really strong for high-stress jobs, like airplane or car parts.

- 5052 Aluminum: Awesome at fighting rust in wet places, like medical settings.

Think about where the part will be used. How strong does it need to be? Are there any rules to follow? These questions help you choose wisely.

Importance of Tolerances and Precision Levels in CNC Processing

Being exact is the heart of CNC processing. Here’s why it matters:

- Tight Fits: Parts must meet exact plans for fit and function. This is critical in complex setups.

- Quality Checks: Strict testing ensures accuracy. This cuts down on errors and flaws.

- High Precision: Super accurate parts are key for fields like airplanes. Even small mistakes can cause big issues.

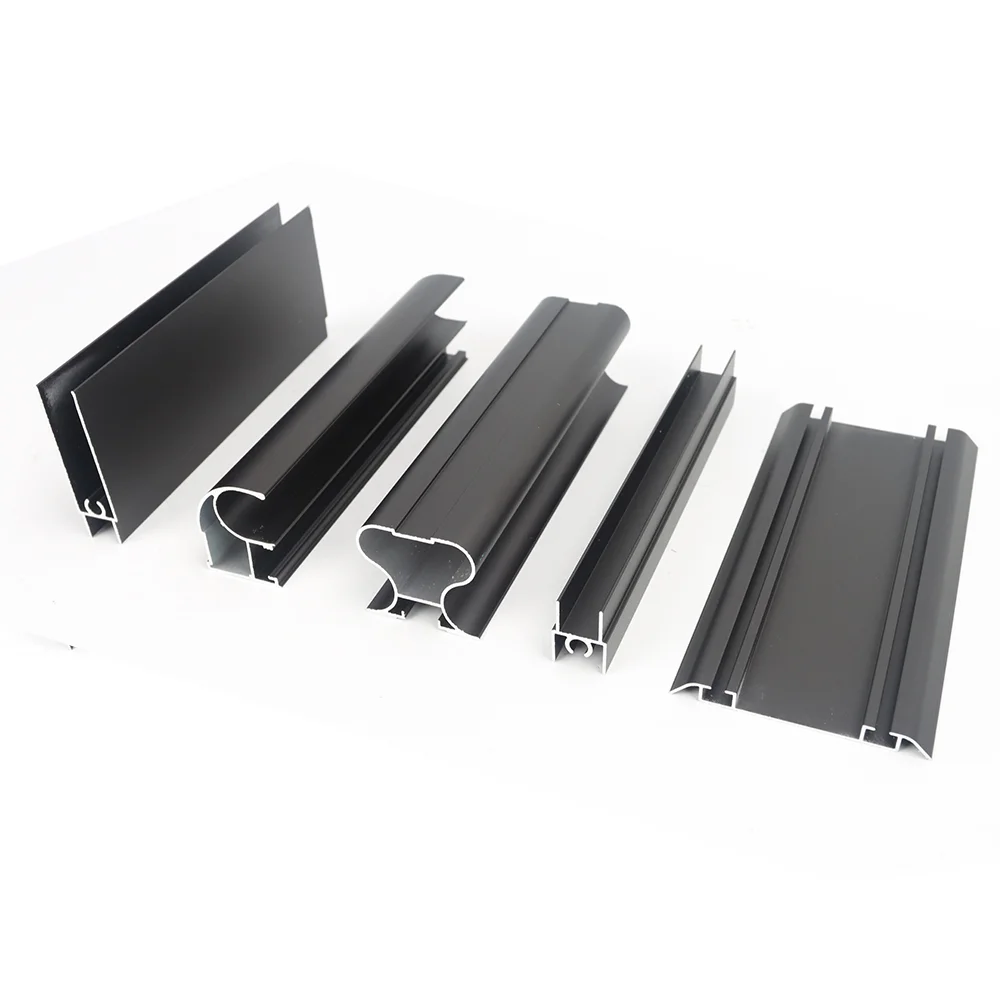

Surface Finishing Options for Aluminum Alloys

Surface finishes make parts work better and look nicer. Popular options include:

- Anodizing: Adds rust protection and lets you choose colors. It’s great for tough environments.

- Polishing: Creates smooth, shiny surfaces. This is perfect for items people see.

- Powder Coating: Makes parts tougher for heavy use. It adds extra strength.

XiHui Aluminium: A Reliable Partner for Aluminum Alloy Customization

At XiHui Aluminium, we’re proud to be a trusted helper for industries needing custom aluminum alloy solutions. Our skills in high-precision CNC processing let us deliver parts that meet the highest standards.

Expertise in High-precision CNC Processing

We’ve got years of experience and bring great skill to every project. Here’s what we offer:

- Cool Technology: Our 5-axis CNC machines handle tricky designs with super accuracy. They’re like high-tech artists.

- Quality Promise: Every piece gets strict testing to ensure it’s perfect. No flaws slip through.

- Custom Solutions: From test runs to big orders, we tailor parts to fit your needs.

Check out our skills at XiHui Aluminium to see how we can improve your making process.

Commitment to Quality and Customer Satisfaction

We’re all about delivering awesome work and building strong partnerships. Our approach includes:

- New Ideas: We stay up-to-date with the latest machining tricks. This ensures top-quality parts.

- Working Together: We listen to what you need. Then, we build parts that match your vision.

- Helpful Support: Got a question? Our team is ready to help. Contact us to talk about your next project.

Conclusion

High-precision CNC processing is the top pick for customizing aluminum alloys. It offers great accuracy, flexibility, and savings. Whether you’re working in airplanes, cars, electronics, or medical gear, this method delivers parts that are strong, exact, and budget-friendly. At XiHui Aluminium, we combine advanced CNC skills with a focus on quality. This makes us the perfect partner for your customization needs. Let us help you bring your ideas to life with parts that go beyond what you expect.

FAQs on High-precision CNC Processed Aluminum Alloys

Q1 What are the advantages of using aluminum alloys in CNC processing?

A1 Aluminum alloys are light, rust-proof, and easy to shape. This makes them awesome for CNC processing. They’re strong yet light, last in tough places, and can be customized for specific designs. Plus, they’re affordable and reliable.

Q2 How does high-precision CNC processing ensure better product quality?

A2 High-precision CNC processing uses computer-guided tools to hit exact measurements. It gives steady results every time. Automatic systems cut out human errors. Multi-angle machines handle complex designs. This ensures every piece meets strict plans for top quality.

Q3 Can small businesses benefit from customized aluminum alloy solutions?

A3 Yes, absolutely! CNC processing is budget-friendly for small runs. It lets small businesses test ideas or make low-volume parts without high costs. Customization ensures parts fit specific needs. This helps smaller companies compete with high-quality, tailored products.