In today’s fast-paced manufacturing world, companies need quick, accurate, and effective solutions. Working with different suppliers for extrusion and machining causes problems, slows things down, and creates risks. This can hold back new ideas. The answer is a strong, combined approach: pairing high-volume aluminum extrusion with precise CNC machining in one place. This teamwork simplifies the supply chain. It turns raw materials into perfect, finished parts. By choosing a single, skilled partner, you can speed up your product launch, improve quality, and gain a big advantage over competitors. This article explores the great benefits of this all-in-one fabrication model and how it leads to success in modern manufacturing.

The Power of a Unified Workflow: More Than Just Manufacturing

Why deal with the hassle of multiple suppliers when one partner can handle your entire project? The real value of an all-in-one service goes beyond just making parts. It creates a smooth system of responsibility, skill, and speed. This directly boosts your profits and keeps your project on track.

Greatly Shortened Wait Times

Using multiple suppliers often leads to delays. You face issues like shipping materials between locations, getting separate quotes, and repeating quality checks. A combined workflow removes these obstacles. What used to take weeks of outside coordination now takes just days of in-house management. This keeps your project on schedule.

Major Cost Savings

The financial benefits are clear and varied. You avoid extra shipping and handling costs. You reduce the time spent managing multiple orders. You also cut down on wasted materials. A single partner can offer smart advice on designing parts to save money. For example, they might suggest small changes to your design. These changes can lower machining time or reduce material use, saving you cash.

Strong Quality Control & Risk Reduction

A single workflow means one point of responsibility. For instance, the T6 temper of an aluminum profile comes from specific heat treatments after extrusion. This affects how the material behaves during machining. A unified team knows this connection well. They ensure the extrusion process avoids internal stresses. These stresses could cause warping or size errors during CNC work. This thorough approach ensures full material tracking and delivers a perfect final product.

From Raw Profile to Precision Part: A Deep Dive into Our Capabilities

Turning a basic aluminum extrusion into a complex, critical part requires a perfect mix of advanced tools and deep know-how.

The Art and Science of Aluminum Extrusion

The process starts with choosing top-quality aluminum billets. These are heated to an exact temperature. Then, they’re pushed through a strong steel die. This creates long, even profiles with great consistency.

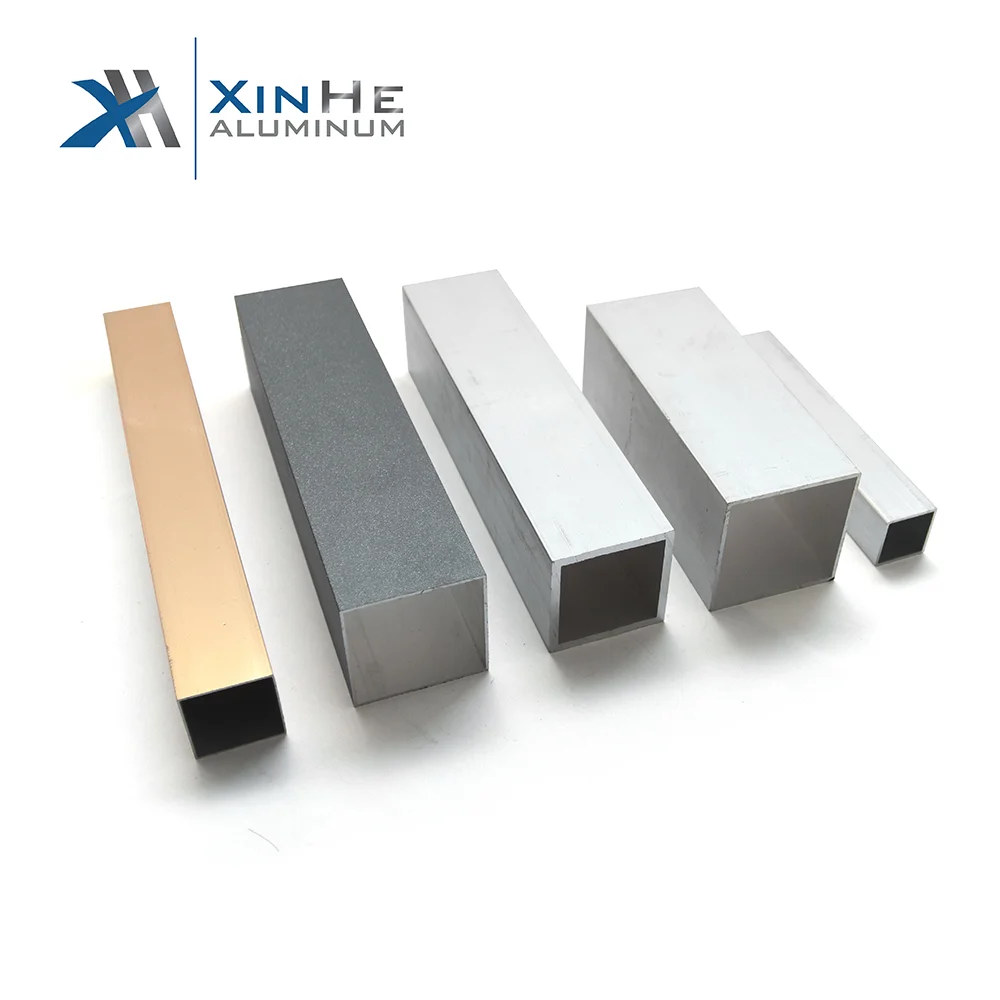

Picking the right alloy is key for performance. We help clients choose from our wide range of options, including:

- 6061 Aluminum: Famous for its strength and solid mechanical features, it’s a top pick for structural parts and machine components. Often provided in a T6 temper, it offers a great mix of strength, weldability, and ease of machining.

- 6063 Aluminum: Valued for its smooth surface and resistance to rust, it’s the go-to choice for architectural parts, window frames, and components where looks matter.

A raw extrusion is just the start. We offer a full set of surface treatments to improve both toughness and appearance:

- Anodizing: Adds a tough, ceramic-like layer that greatly boosts resistance to corrosion and wear.

- Powder Coating: Gives a strong, thick, and protective finish in nearly any color you can imagine.

- Sandblasting & Polishing: Creates unique surface textures, from a smooth matte look to a shiny, mirror-like glow.

The Precision of CNC Machining

After extrusion, profiles move to our advanced secondary processing stage. Here, our 40 modern CNC machining lines turn possibilities into reality.

Our capabilities cover a wide range of CNC processes, each suited for specific needs:

- Milling: Perfect for creating not only simple features but also complex 3D shapes and surfaces. These are needed for advanced parts like heat sinks and machine housings.

- Turning: Used to make round parts with high accuracy, such as shafts, connectors, pins, and custom fittings.

- Drilling & Tapping: Provides precise holes and internal threads for assembly. This ensures parts fit together perfectly every time.

We excel at pushing limits, achieving tight wall thickness tolerances as fine as 0.4mm. This is a highly skilled task. Thin walls can vibrate or deform due to heat during fast machining. Our expertise and top-notch equipment solve these problems. We deliver lightweight parts for aerospace, medical devices, and electronics. These parts stay strong and reliable.

XiHui Aluminium: Your Partner in Precision Fabrication

For over 30 years, XiHui Aluminium has been a trusted global leader in combined aluminum manufacturing. Founded in 1993 and based in the busy industrial hub of Foshan City, we act as a true all-in-one partner. We guide projects from the first idea to final delivery.

A Legacy of Expertise and Trust

Our facility is a hub of production. It’s equipped with 15 extrusion lines and 40 advanced CNC machining lines. This huge capacity, paired with our collection of over 10,000 existing molds, offers unmatched design flexibility and speed. Guided by strict ISO-certified quality systems, we proudly serve clients in over 120 countries. We deliver parts that meet the highest global standards.

Manufacturing Powerhouse and Global Reach

We provide complete OEM/ODM services. Our team of skilled engineers offers expert advice on design, assembly, and logistics. From secure, multi-layer packaging to dependable global shipping, every part of our service ensures your project’s success. We provide a smooth, reliable supply chain experience. Trust XiHui Aluminium to act as an expert extension of your own team.

Frequently Asked Questions (FAQs)

Q1: What is the minimum order quantity (MOQ) for custom aluminum profiles?

A: Our MOQ is designed to be flexible. For anodized finishes, the MOQ is 500 kg per model. For our wide range of powder-coated or wood grain finishes, the MOQ is 2,000 kg (2 tons) per color. This ensures efficient production.

Q2: Can I request a free sample before placing a bulk order?

A: Yes, definitely. We encourage you to request a sample. This lets you check the accuracy, finish, and overall quality before starting a full production run.

Q3: How does XiHui Aluminium ensure the quality of its CNC machined parts?

A: Quality is our top priority. We use a centralized, ISO-certified quality control system. It carefully checks every step, from the raw billet’s chemical makeup to the final size check on our 40 advanced CNC lines.