Custom CNC machining is super important in today’s manufacturing world. It takes raw materials and turns them into detailed, top-notch parts with awesome precision. This process is flexible and can handle big or small orders, which makes it a go-to for industries like aerospace, cars, electronics, and medical tools.

Aluminum alloys are a favorite material for this work. They’re easy to shape, light but tough, don’t rust easily, and carry heat well. These qualities make aluminum great for parts that need to be both lightweight and strong. As industries ask for trickier shapes and super-precise measurements, the need for accuracy and great customer support in CNC machining keeps growing. Companies have to nail technical details, deliver fast, and offer friendly, hands-on help.

Evolution of Aluminum Alloy CNC Machining

Aluminum alloys in CNC machining have come a long way. Back in the day, people used manual tools and basic machines, so designs were simple, and production was limited. Then, in the mid-20th century, computer numerical control (CNC) systems showed up. These made things way more precise by automating tasks. They cut down on mistakes and let people create more complex parts.

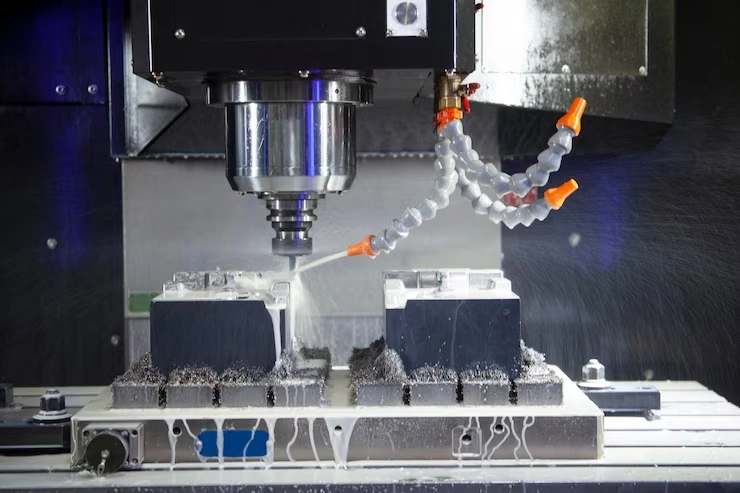

Big steps forward include machines that move in multiple directions at once. Also, CAD/CAM software made it easy to go from a digital sketch to a real part. These upgrades opened up tons of customization options. Now, CNC machining gives spot-on measurements and custom solutions. We focus on being flexible and putting customers first, handling everything from design to shipping.

Balancing Quality and Service in Custom CNC Machining

In CNC machining with aluminum alloys, getting quality and service just right is the key to doing well.

Defining Quality Standards in CNC Machined Aluminum Parts

Quality means getting measurements super accurate. Modern CNC machines can hit tiny, exact sizes, so parts fit perfectly in bigger setups. Picking the right material is a big deal too. We use high-quality aluminum to make sure parts are strong and don’t rust. We track every batch from start to finish to keep things consistent.

The surface finish is also a big factor. Whether it’s anodizing or powder coating, the finish has to look good and be the same on every part. Our modern setup, with top-notch anodizing and coating lines, makes sure products are tough, look nice, and work better than expected.

Service Excellence as a Competitive Differentiator

Great service isn’t just about delivering fast. It’s about helping clients every step of the way. Quick delivery matters a lot. We get parts to you in 20–25 days, plus 10 days if we need to make a mold. This keeps your project on track without cutting corners on quality. Talking clearly with clients is another strength. We give advice on designs or materials to avoid pricey fixes later.

Being flexible is key too. We can handle small test runs or tweak designs during production. With a minimum order of 500 kg per design, we work with projects big or small.

Setting Industry Standards Through Innovation

Staying ahead in CNC machining means coming up with new ideas. Smart systems now watch the process as it happens. This cuts down on waste and keeps things under control. Automation makes work faster and more consistent. Being eco-friendly is also a big deal. Using recyclable aluminum fits with green manufacturing goals.

Certifications like ISO 9001 prove we meet global quality rules. This makes international clients trust us as reliable partners.

XiHui Aluminium: Driving Excellence in Custom CNC Machining

XiHui Aluminium shows how to lead with new ideas and awesome service.

Company Overview and Core Competencies

XiHui started with a goal to help construction and industrial fields worldwide. We focus on custom aluminum alloy profiles and offer full ODM and OEM services.

Development Journey in the Field of Aluminum Alloy CNC Machining

XiHui has put a lot into modern tools, like automated cutting lines and precise machining centers. These let us produce lots of parts while keeping every detail and finish perfect. Our team is skilled—engineers make designs easier to build, and technicians check every step for mistakes. We keep improving to stay competitive on quality and price. Most importantly, we build trust with clients for long-term partnerships. Our all-in-one service makes things easy for construction contractors, from picking materials to getting parts delivered.

Applications Across Industries

Custom CNC machined aluminum parts are super useful in many areas:

- Aerospace: Light, strong parts like brackets or casings.

- Cars: Pieces that help save fuel by being lightweight.

- Electronics: Heat sinks and covers that use aluminum’s heat-moving ability.

- Medical Tools: Clean, precise casings for surgical gear or diagnostic machines.

Surface Finishing Options for CNC-Machined Aluminum Parts

Surface treatments make parts look better and work better:

- Anodizing (Type I/II/III): Stops rust. Type III adds a tough layer for parts that get heavy use.

- Powder Coating: Adds color and protects against scratches.

- Bead Blasting & Brushing: Gives a smooth, even look.

- Chemical Conversion Coating (Alodine): Helps paint stick and offers some rust protection.

Our products come in finishes like shiny anodized silver or different powder coatings.

Order Quantities and Production Flexibility

We handle orders of any size, from one test part to thousands. Prototyping lets clients try out designs before going big, which lowers risks. Our mass production is set up for speed and consistency but never skips on quality. With a minimum order of 500 kg per design, we make it easy for special orders with unique needs.

FAQs:

Q1: What types of aluminum alloys work best for custom CNC machining?

A: Alloys like 6061-T6 and 6063-T5 are popular. They’re easy to shape, light but strong, don’t rust much, and come in different forms for various uses.

Q2: How does XiHui make sure quality stays high during production?

A: We check everything carefully at every step. We start with traceable, top-quality aluminum. Final finishes get inspected with modern systems like anodizing or powder coating lines. Our setup makes sure every part beats industry standards.

Q3: Can I order small batches or ask for custom designs?

A: Totally! With a minimum order of 500 kg per design, we do small test runs or big production jobs. We customize based on your sketches or samples through our flexible ODM and OEM services. This all-in-one approach makes things smooth for construction contractors.