In today’s engineering-focused sectors, the need for lightweight, rust-proof, and very precise parts has reached a peak. Fields like aerospace, automotive, medical, and electronics demand components that satisfy strict tolerances. Aluminum stands out, particularly when shaped via CNC methods. It boasts a great balance of strength and weight, easy workability, and good heat transfer.

CNC machining delivers outstanding consistency and accuracy. Tailoring fits right into this setup. Engineers now build components from scratch for particular uses. These range from sturdy frames in electric vehicles to heat-efficient casings in LED lights. Moreover, this approach boosts innovation across various applications. It ensures that each part meets exact needs without unnecessary bulk.

For businesses aiming to simplify their supply lines while upholding top performance, Xihui Aluminium provides a full-service option. Xihui Aluminium Company supplies carefully made, custom CNC-machined aluminum profiles designed for demanding fields. They blend cutting-edge CNC machining with tolerances of ±0.01mm, top-quality alloys from aerospace, like 6061 and 7075, and complete services. This end-to-end support reduces lead times and cuts costs effectively.

Microstructural Characteristics of Aluminum Extrusion vs Casting

A major difference in microstructure shows up in the shape of the grains formed during production. This lined-up pattern comes from the strong pulling and bending forces applied in extrusion. On the other hand, cast aluminum hardens right where it is poured. This leads to round, tree-like grains scattered in all directions. Therefore, examining these patterns under a microscope reveals the method used. Such details not only show the process but also explain traits like uneven strength or tiredness under repeated stress. In practice, this helps engineers choose the right material for specific loads.

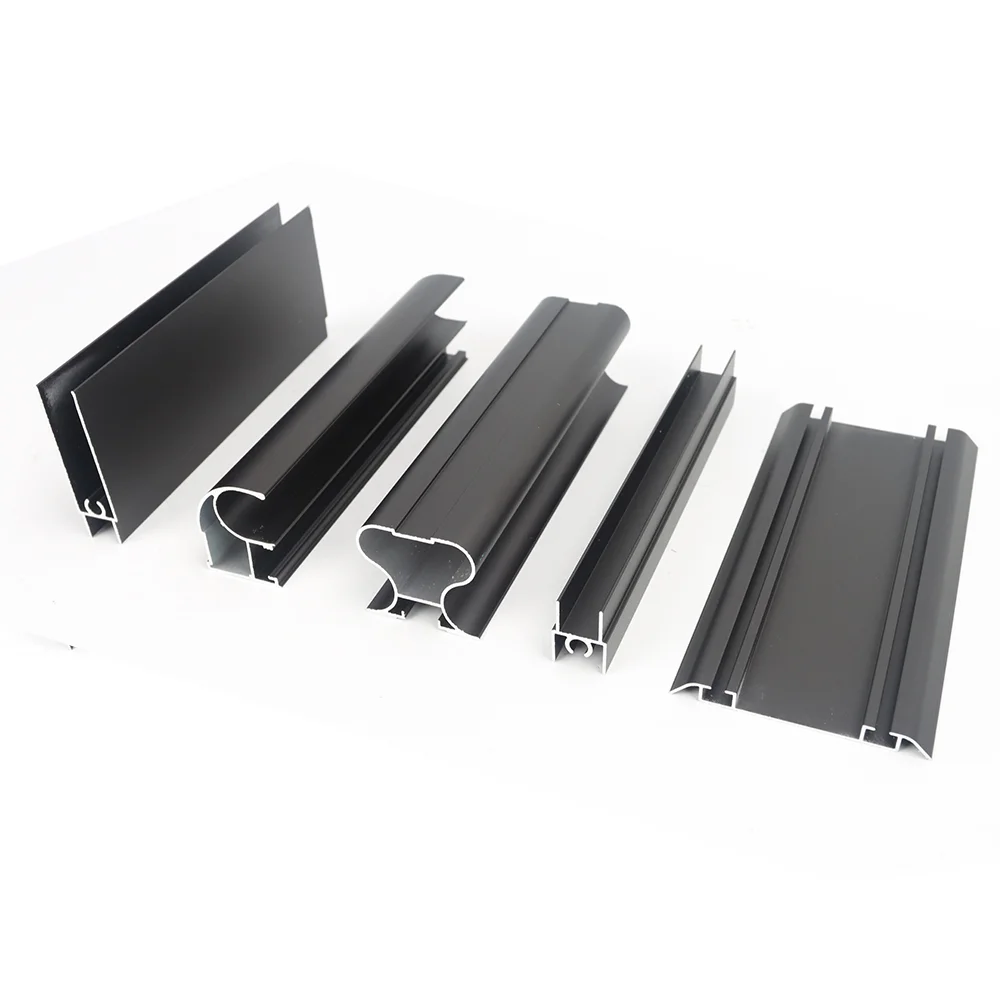

How Does Surface Texture Offer Visual Hints About Manufacturing?

Extruded pieces usually display straight lines or flow lines that follow the extrusion path. These come from rubbing against the die during shaping. The lines stay even across the surface. Secondary steps, like anodizing or smoothing, can reduce them further. Cast surfaces, by comparison, often look rougher. They might have marks from shrinking as it cools, trapped air bubbles, or raised spots. You can spot these with a closer look. They point to how the material cooled inside the mold. Consequently, these clues guide quick checks in quality control without needing deep analysis every time.

Are Inclusions and Internal Defects Telltale Signs?

Cast aluminum tends to pick up flaws more easily. These include thin oxide layers, trapped gases creating holes, or bits of non-metal added during melting and pouring. Extruded shapes are generally purer. The starting blocks for extrusion get heated evenly and cleaned of gases first. So, they start with fewer issues. Looking at thin slices under a microscope, spots casting-specific problems like tiny shrinks or uneven metal spread between grain branches. You seldom see these in extruded items unless the raw material was dirty. This purity in extrusions often leads to better overall reliability in final products. It minimizes failures in high-stakes uses.

How Do Mechanical Properties Reflect the Forming History?

Thanks to bending and stretching, plus possible heat treatments after extrusion, such as T5 or T6 states, extruded aluminum usually shows greater resistance to bending and harder surfaces than raw cast versions. Cast pieces might absorb vibrations better, but often bend less before breaking. Mapping hardness over a sample uncovers changes tied to hardening from work in extrusions or weak spots from holes in castings. These variations directly link back to how the material was shaped and treated. Understanding this helps predict how parts will perform under real-world conditions. It also informs decisions on further processing to boost durability.

Metallurgical Analysis Techniques for Differentiation

Optical microscopy serves as the initial tool in metal studies. After polishing and etching cross-sections, experts can tell stretched grains apart from tree-like ones. The former suggests extrusion, while the latter indicates casting. This approach also spots edges between grains, extra particles, and any breaks. By doing so, it provides a clear picture of the material’s background. Such insights prove valuable for troubleshooting issues in components. They ensure that the right manufacturing path is followed from the start.

How Does SEM Deepen Insight into Defect Analysis?

Scanning Electron Microscopy, or SEM, gives much sharper views for studying break patterns and spotting unwanted bits. In cast examples, it highlights areas of uneven metal mixing and oxide skins. For extruded ones, SEM might show fine lines inside grains or paired structures from stress during shaping. These details go beyond basic views. They uncover subtle effects of the process on the material’s inner structure. As a result, engineers gain a fuller understanding of potential weak points. This knowledge supports improvements in production to avoid future problems.

Can X-Ray Diffraction Identify Crystallographic Orientation?

Extruded aluminum displays a clear favored direction from the way the metal moved. Castings show more mixed-up alignments, except in cases of guided cooling. Stress left inside also varies. Extrusions can hold onto tensions from fast cooling or uneven pulling, which XRD picks up as wider or shifted peaks. Therefore, this technique not only confirms the origin but also assesses ongoing stresses. It aids in ensuring parts remain stable over time in demanding environments.

Process-Based Clues Beyond Microstructure

Marks from tools on extrusions run straight and steady because of steady contact with the die as it forms. Sizes stay uniform along the length, owing to precise die shapes. Cast items, however, often have sloped sides for easy removal from molds, seams where mold halves meet, or size changes from cooling shrinkage. These traits make identification straightforward during inspections. They reflect the practical challenges of each method. Spotting them early helps maintain quality standards across batches.

How Does Heat Treatment Point to Processing History?

Extrusions frequently get artificial heating, like in the T6 state, to build strength through tiny hardened spots. This boosts mechanical traits but requires exact timing right after shaping. Cast parts might need even heating first to blend out uneven areas and ease later cutting. Such steps tie directly to the initial forming. They shape the final properties in ways that match the application’s demands. By reviewing treatment records, one can trace back to the core process used.

XiHui Aluminium: Precision CNC Solutions for Custom Aluminum Profiles

Fitted with 5-axis CNC machines, fast-turning heads, and auto tool swaps, Xihui Aluminium handles intricate shapes with smooth finishes. Their large stock of 6000-series aluminum alloys matches varied needs. Using CAD/CAM links and backward design skills, they tailor items from plans or samples while holding tight limits. This setup allows for quick adaptations to client specs. It ensures that every project aligns perfectly with performance goals.

What Quality Control Practices Are in Place?

Their ISO 9001-approved methods guarantee long-lasting, light parts with strong resistance to rust and solid heat flow. Standard checks include CMM measurements, alloy checks via spectrometers, and tests for surface smoothness. These steps catch issues early and verify compliance. As such, clients receive products that meet or exceed expectations. This rigorous approach builds trust and supports repeat business in global supply chains.

Which Industries Trust XiHui Aluminium?

With years of work in areas from aerospace structures to everyday gadgets, Xihui has sent vital parts around the world. For instance, they finished a set of linked components for an EV maker sooner than planned, with under 1% waste. This track record shows their ability to scale up reliably.

Service Offerings at XiHui Aluminium

Key CNC services include: turning, precise concentricity for shafts and pins. Milling: ideal for pockets, contours, and slots. Drilling: accurate hole positioning for assemblies. Laser cutting: clean edges without mechanical stress. This variety covers a wide range of part requirements. It allows for one-stop solutions that streamline production workflows effectively.

Which Applications Rely on Custom CNC Aluminum Parts?

Common sectors include: aerospace: weight-sensitive parts that require fatigue resistance. Automotive: connectors and housings for EVs. Electronics: enclosures requiring EMI shielding or heat sinks. For example, their custom 5-axis CNC milling service is ideal for automotive components needing multi-directional precision. These applications benefit from aluminum’s natural advantages. They push the boundaries of design while maintaining safety and efficiency.

What Surface Finishing Options Enhance Functionality?

Options include anodizing: corrosion resistance plus color coding. Sandblasting: matte texture for visual appeal. Powder coating: Durable colored coatings. Polishing: high-gloss finishes. They add layers of protection that extend part life. This thoughtful selection ensures optimal performance in real settings.

Customer Support & Collaboration

Clear channels keep everyone aligned from concept to completion. Workmanship warranties ensure peace of mind. Clients benefit from feedback loops that allow continuous product refinement throughout long-term partnerships. These measures address any concerns promptly. They foster strong relationships built on reliability. Over time, this support evolves with client needs, driving mutual growth.

Project Highlights from XiHui Aluminium. Delivered complex assemblies ahead of schedule for an electric vehicle OEM. Supplied aerospace brackets with <1% rejection rate over 10k-unit batch. Produced anodized enclosures with ±0.005mm tolerances for a medical device client. They demonstrate how Xihui turns challenges into successes. Such examples inspire confidence in their services for future endeavors.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC-machined aluminum parts?

A1: The MOQ typically starts at 50 pieces, depending on part complexity; however, prototypes can be arranged upon request to validate design feasibility before bulk production.

Q2: What surface treatment options are available for CNC-machined aluminum?

A2: We offer anodizing (clear or colored), powder coating, sandblasting, polishing, electrophoresis coating, chrome plating (for select alloys), among others—each tailored to functional or aesthetic requirements.

Q3: How does XiHui Aluminium ensure accuracy during custom machining?

A3: Our team employs advanced CNC systems integrated with CAD/CAM software alongside real-time inspection tools such as CMMs (Coordinate Measuring Machines) to maintain high dimensional accuracy throughout production cycles. It minimizes variations and upholds the highest standards in every run.