Aluminum profiles have turned into essential parts in cutting-edge engineering uses. They deliver strong results in fields from aerospace to automation. Their special mix of low weight, solid strength, and flexibility helps engineers create efficient systems. These systems are both sturdy and affordable. As today’s industry needs more accuracy and personalization, aluminum profiles give a flexible answer. This supports new ideas in mechanical setups, casings, and adjustable builds. This piece offers a detailed look at the key perks of aluminum profiles. It also covers their big impact on factory production.

Mechanical Advantages of Aluminum Profiles

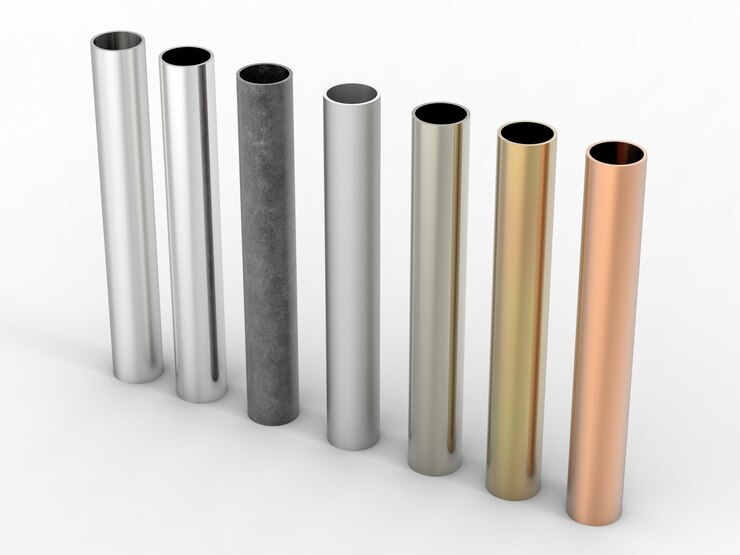

Aluminum profiles are built to provide a strong strength-to-weight balance. This main feature boosts structure work without adding much mass. It matters a lot in areas like aerospace, cars, and factory automation. There, cutting weight improves gas savings, quick response, and energy use. Industrial aluminum profiles are mix materials mainly made of aluminum. They form by heating and pressing aluminum blocks to make shapes with varied sections. Using mixes like 6061-T6 and 6082 lets these profiles handle big loads. At the same time, they keep firmness. This beats many old steel builds in designs that care about weight.

Corrosion Resistance and Surface Durability

A main plus of aluminum profiles is their built-in resistance to rust. Aluminum creates a slim oxide coat when it touches air. This coat shields the base metal from more harm. This natural trait gets better with surface fixes like anodizing and powder coating. The surface has gone through anodizing treatment. As a result, it resists rust, wear, and fits many uses. These fixes boost defense against things like water, chemicals, and sun rays. Thus, aluminum profiles work well for inside and outside jobs.

Thermal Conductivity and Heat Dissipation Capabilities

Aluminum’s good heat flow is another key perk. It aids wide use in cooling gadgets and heat control setups for electronics. Aluminum radiator profiles often go into LED cases, power electronics boxes, and factory machines. They spread heat well. Profiles can include built-in fins or empty paths. This helps top passive cooling. And it does so without needing active parts.

Design Flexibility and Customization Potential

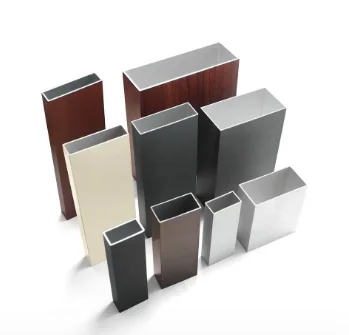

One of the best traits of aluminum profiles is their skill to be pressed into tricky shapes. Aluminum materials with different cross-sectional shapes can fit exact needs. They blend mechanical parts, wire paths, or fix points into one build. This cuts the number of pieces. It also makes putting together easier. Plus, it allows exact, light designs tuned for best work.

Compatibility with Modular Assembly Systems

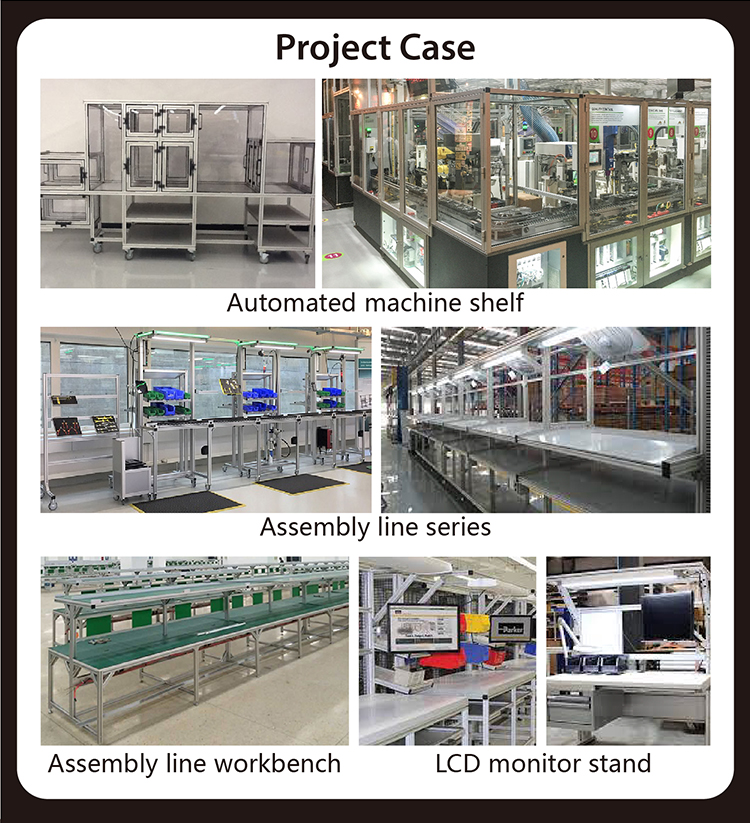

T-slot aluminum profiles often appear in adjustable frames. This comes from their standard slot shape. It allows fast building. Industrial production line profiles use steady or on-off motion of conveyor belts. They move items of varied weights and sizes. These profiles aid changes, test models, and growth in systems. And they do this without welding or special tools. Uses cover machine frames, conveyor setups, test stands, robot arms, and safety boxes.

Surface Treatment Options for Functional Enhancement

Anodizing raises surface toughness and rust defense. It also gives style choices through color anodization. In stock colors: oxidized silver white, oxidized black

Powder Coating

Powder-coated layers boost lasting power. They add scrape resistance and sun guard. People like them for special color needs in building or user-facing jobs. Customizable: Various spray paint colors

Brushed or Polished Finishes

For jobs where looks count, brushed or polished aluminum gives even textures. These suit decor panels or user goods.

Manufacturing Efficiency and Sustainability Benefits

Aluminum works well with common tools and CNC methods. It handles close limits in fast milling, drilling, tapping, and cutting tasks. Supports high-precision CNC machining. This fits low-run CNC work and model making. There, quick changes are key.

Recyclability Without Material Degradation

One of the strongest green perks is that aluminum can recycle forever. It keeps its strength traits. This fits round economy ideas. It helps makers cut carbon marks. And it holds material quality.

Cost Efficiency Across the Product Lifecycle

The low weight of aluminum profiles cuts transport costs in shipping. With their rust defense and small upkeep needs, they save money over time. This happens in tough settings by stretching work periods.

Applications Across Key Industrial Sectors

In automation setups, T-slot aluminum builds are picked for their easy changes. They also mix well with sensors, motors, movers, or conveyors. Automatic equipment protective covers are often made using these adjustable presses.

Transportation: Automotive, Aerospace, Rail

Aluminum’s weight-cut power turns right into better gas use in vehicles and planes. Exact presses go into crash builds, body sheets, and inside support frames.

Electronics Enclosures and Thermal Management

Custom-cut aluminum presses do two jobs. They give structure aid and work as heat sinks for electronics cases. They offer good heat paths. And they ensure electro-magnetic shield when needed.

XiHui Aluminium: Precision Aluminum Profile Manufacturing Partner

XiHui Aluminium focuses on CNC machining help. It stresses custom aluminum extrusion profiles. Our factory has 33 years of making and selling know-how. It holds over ten thousand sets of molds. These cover many design types. The company gives full help. This includes 5-axis CNC machining, anodizing fixes, extrusion die plan advice, and build aid for factory clients. Sectors cover medical tools, car systems, and structure gear.

Commitment to Quality and Innovation

XiHui Aluminium uses ISO-checked quality steps. These make sure material tracking and size exactness all through making. Our group has special build engineers. They can give build drawings and fix ideas based on client needs. With ongoing spends on new making tech, XiHui backs tricky shapes for high-worth uses.

XiHui Aluminium Benefits from Preferential Anti-Dumping Duty Rate in Israel

According to relevant trade measures, XiHui Aluminium has been included in Israel’s “white list” for anti-dumping investigations concerning aluminium products. As a result, the company is subject to a significantly lower preferential duty rate of 37%.

In contrast, other Chinese aluminium exporters not listed on this white list face a substantially higher anti-dumping duty of 110%. This stark difference highlights the critical advantage gained by XiHui Aluminium through its compliance and successful response to the investigation, allowing it to maintain relative price competitiveness in the Israeli market.

Key Benefits of Aluminum Profiles

Top strength-to-weight balance boosts structure work across uses. Strong rust defense makes sure long lasting in rough spots. Design ease lets mixing into adjustable systems. It cuts build trouble.

Strategic Value Across Industries

Aluminum profiles help makers create new things fast. This comes through custom fit and model skills. Their recycle power backs green aims too. It lowers full life costs.

FAQ

Q1: Can aluminum profiles be used in high-load structural applications?

A1: Yes, when built right with fitting section shapes and mix picks (e.g., 6061-T6 or 6082), aluminum profiles can hold big loads. They keep lower weight than steel choices.

Q2: What surface treatments are recommended for enhancing durability?

A2: Anodizing often boosts rust defense. Powder coating adds wear guard. Both choices also lift looks based on the job setting.

Q3: How does XiHui Aluminium support custom profile development?

A3: XiHui Aluminium gives full-end help. This covers CAD model check, die plan advice, extrusion making, CNC machining exact help, anodizing finish picks. It makes sure client needs meet well.