In the current manufacturing landscape, the need for accuracy, a strong strength-to-weight balance, and rust resistance has turned aluminum CNC machining into a vital foundation in various fields. Each use calls for unique forms and strict limits. A main reason for this growth is the increasing intricacy in designs and output needs, especially in electric vehicles, automation setups, and everyday gadgets.

Custom aluminum CNC machining profiles can be adjusted for light frames, parts that release heat well, or eye-catching pieces for consumers. This range makes it a top pick in efforts that need both practical use and nice looks. When basic extrusion shapes do not meet exact output or fitting standards, custom machining fills that space well. Engineers often turn to these options to handle detailed requirements without much hassle. Moreover, the process allows for quick changes based on project goals.

XiHui Aluminium supplies precise, made-to-order CNC machined aluminum profiles built for key performance areas in industries. They mix top-notch CNC machining with tolerances of ±0.01mm, alloys at aerospace level like 6061 and 7075, and full services from fast prototypes to final surface work. Their approach ensures parts that fit seamlessly into demanding setups.

What Shapes Are Most Commonly Used in Aluminum Extrusions?

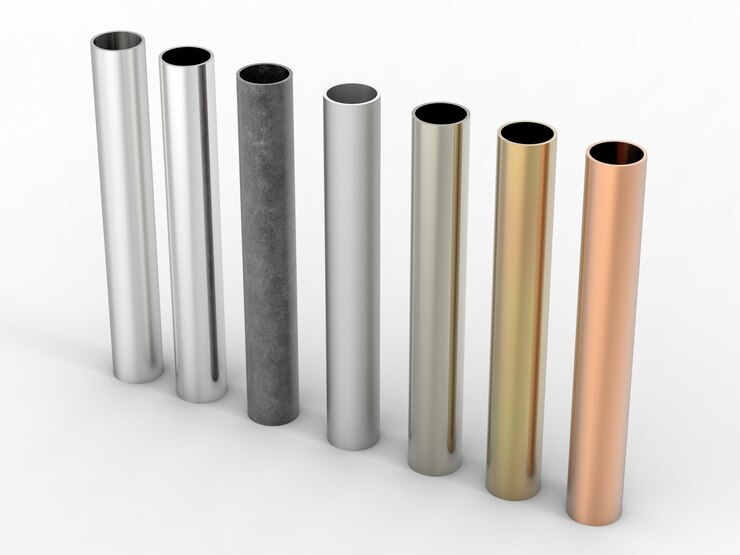

Aluminum extrusions usually fall into three main groups. First, there are solid profiles. These cover rods, flat bars, angles, and channels. They stay dense in structure and serve spots where power matters most. Next come hollow profiles. Tubes in round or square forms, plus rectangular boxes, give great strength against weight. People use them often in tasks like pipes or protective cases. Finally, semi-hollow profiles appear. These have partly closed sections with some openings. They provide a middle ground in strength and weight features. Overall, these groups help meet diverse needs in building and design.

How Do Engineers Choose the Right Shape?

Selecting the best shape comes from mixing mechanical, heat-related, and look-based demands. For structural load-bearing, shapes like I-beams or T-slots work best in tough stress spots. They hold up under pressure without bending. When thermal performance counts, forms that boost surface space, such as finned tubes or heat sinks, aid in smooth heat spread. This keeps devices cool during operation. For visual design and finish work, options like U-channels or trim pieces suit items seen after setup. Engineers weigh these factors to pick what fits the job. In practice, they test options to ensure long-term success. This careful choice leads to reliable outcomes in real-world uses.

Which Shapes Dominate Industry Use Cases?

The top shapes in common use include T-slot aluminum profiles. They shine in the setup for modular frames. Then, U-channels and L-brackets stand out for building frames and supports. These provide steady backing in assemblies. Round tubes also appear a lot. They suit car pipes and cases for electronics. Each of these fills specific roles across fields. For instance, T-slots allow easy adjustments in machinery builds. U-channels offer simple edging for panels. Round tubes handle fluid flow in systems. This variety ensures broad application.

What Applications Rely on Aluminum Extrusion?

The aerospace field needs materials that pair low weight with solid strength. Aluminum extrusions hit this mark exactly. They cut down on plane mass while keeping toughness intact. Workers use them in tracks for seats, frames for windows, builds for cabins, and covers for avionics. These parts help planes fly efficiently and safely. Without such light yet strong elements, designs would suffer in performance. Thus, extrusions play a central role in advancing flight tech.

How Does Automotive Manufacturing Benefit?

Aluminum extrusions add a lot to today’s car builds. In electric vehicles, they form battery trays and channels for cooling. This setup lowers weight and manages heat better. Also, hollow profiles go into crash systems and roof rails. They take in impact force while holding shape. Such uses improve safety and fuel savings. Manufacturers rely on them to meet strict rules on emissions and speed. Over time, these extrusions have become essential for modern rides, from small cars to large trucks.

What Role Do Extrusions Play in Electronics?

Gadgets sensitive to heat gain hugely from aluminum extrusions shaped as heat sinks. Our extruded aluminum heat sinks provide strong heat release, light build, and lasting strength. They ensure good heat control for electronic items. Cases from extruded profiles also shield insides and allow flexible housing for tricky setups. This combo protects circuits and aids cooling. In fast-paced tech worlds, these features keep devices running smoothly. Engineers pick them for reliability in daily tools like phones and computers.

Are There Architectural Uses?

Yes, there are many. They bring good looks and firm work. Anodized layers boost weather resistance. This makes them perfect for business and home buildings. Such uses blend style with endurance. Builders choose them to last through seasons. In cities, these elements shape modern views while standing strong.

Who Is the Ideal Manufacturer for Custom Aluminum Profiles?

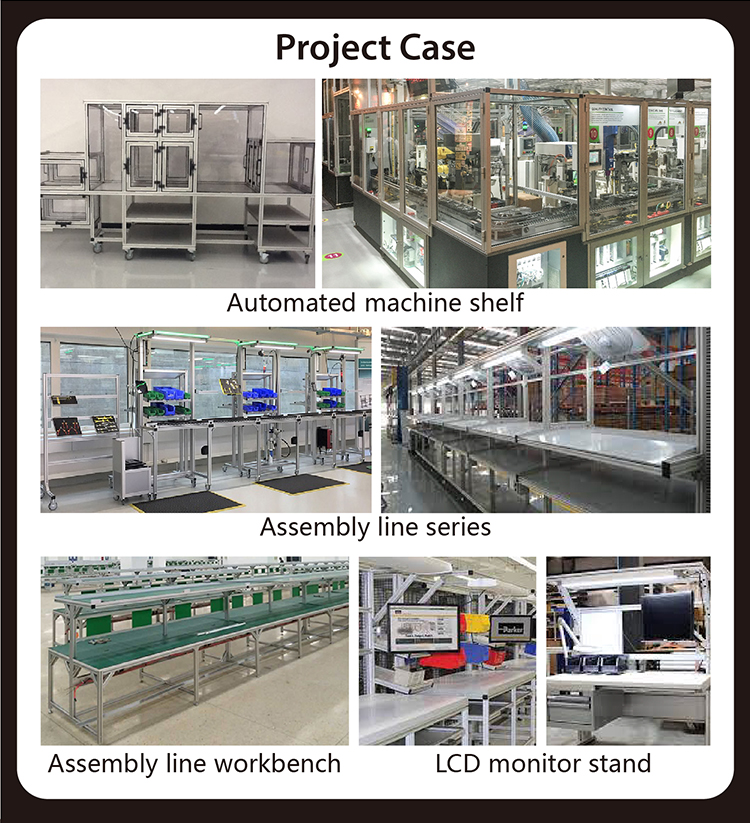

If you want a reliable teammate with solid skills in custom aluminum machining, look at XiHui Aluminium. Located in Foshan, they bring more than 30 years of know-how. XiHui runs over 15 extrusion lines and more than 40 CNC machines. These include 3-, 4-, and 5-axis types. Their team of engineers focuses on turning detailed CAD files into ready-to-make items. They use top alloys such as 6061 and 7075. This process covers every step with care. From drawing reviews to final checks, nothing gets overlooked. Their setup handles large runs or small tests alike.

With ISO 9001 approval, their methods guarantee tough, light parts that resist rust and conduct heat well. Tools like CMM for measurements and built-in quality checks provide steady control over groups of items. High match rates come standard. Clients trust this for consistent results. In short, XiHui stands as a go-to for quality-focused projects.

Which CNC Machining Processes Are Available?

What Are the Core Capabilities?

Key skills cover several areas. Turning creates even parts like bushings or spacers. It spins material to shape rounds smoothly. Milling suits cuts for pockets, slots, holes, and outlines on hard surfaces. This method removes bits precisely for custom fits. Drilling and tapping set exact hole spots and add threads for joining parts. Each process builds on the last to form complete pieces. Together, they meet wide needs in production.

What Surface Treatments Can Be Applied?

Several finishes work after machining. Anodizing builds a shield against rust and adds color choices. It layers the surface for a better life. Powder coating and sandblasting give a soft look or help paint stick. These steps prepare for outdoor use. Brushing and polishing create high-end shines for parts in view. They smooth and brighten metal nicely. Depending on the goal, teams pick the right one. This adds value and protection to the base work.

Which Industries Use Custom CNC Aluminum Parts?

In aerospace, custom CNC aluminum parts fit into brackets, covers for sensors, and light builds are vital for avionics. These elements link systems without adding bulk. They ensure smooth function in tight spaces. Pilots and crews depend on such precision for safe flights. Over missions, these parts prove their worth in extreme conditions.

Why Is the Automotive Sector Dependent on These Solutions?

The car world leans on these for electric vehicle bases. They shape battery trays, plates for cooling, and housings for motors. CNC aluminum machining offers good heat flow and easy shaping. This suits fast-paced builds. From design to road, these parts boost efficiency. Teams use them to cut costs and improve range in EVs. Without them, progress in green transport would slow.

What Role Do They Play in Electronics?

Custom enclosures from these parts guard inner wires while balancing heat. They fit exactly for power units or frames in wireless setups. Tailored for automation, automotive, and green energy tasks, they provide tight matches. This keeps electronics safe and cool. In crowded boards, precision matters most. Such parts enable smaller, smarter devices overall.

What Customer Support Services Are Provided?

Customers get quick quotes from CAD sketches. Prototypes start in just days. Digital flows speed this up. No long waits mean faster project starts. Teams review files right away to suggest tweaks. This quick pace helps meet deadlines. In busy markets, such speed builds trust. Help goes on after shipping. It includes tips for setup, ways to use best, and swaps if covered by warranty. Experts are available for questions. This full care keeps clients happy long-term. From first contact to ongoing use, support remains strong. It turns one-time buys into lasting ties.

Why Choose XiHui Aluminium as Your Supplier?

XiHui blends the latest CNC skills with broad know-how in aerospace, automotive, medical tools, and consumer gadgets. They offer full answers from basic drawings to delivery. Their edge comes from focus on clients, covering quick tests to big runs, with quality checks at each point. This setup suits varied needs. For tough jobs, they deliver on time and spec. Their Custom Industrial 5 Axis CNC Milling Turning Service shows skill in making complex aluminum items. Clients gain from this reliable path. In competitive fields, such partners drive success forward.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom aluminum CNC machining?

A1: Most projects can begin with a minimum order quantity of 10–50 pieces, depending on part complexity and material availability.

Q2: What surface treatment options are available after CNC machining?

A2: Common options include anodizing (clear or color), sandblasting, powder coating, brushing, polishing, and electrophoresis coating, depending on the application needs.

Q3: Does your company provide structured data markup to enhance search visibility?

A3:Yes, product pages can be integrated with Schema.org structured data, such as Product markup, to improve SERP rich results visibility when required by clients’ or resellers’ websites.