The world of manufacturing today focuses on quick production, detailed designs, and exact standards. Custom aluminum CNC machining plays a central role in this field. It supports items like modern medical tools and new car parts. Aluminum stands out because of its good balance of strength and light weight. Plus, it offers lasting durability and useful heat handling.

But designs for products are getting more detailed now. They include deep spaces, tricky shapes, and strict size limits. Basic ways to make things often cannot handle these needs well. The industry calls for methods that not only match but go beyond these tough tasks. And they must do so in a smooth and steady manner.

Here comes a big change. It means going past the usual 3-axis setup and using the better features of 5-axis CNC technology. This key step opens up great freedom in shapes and exactness for your important custom aluminum parts.

The 3-Axis Barrier: Why Traditional Machining Hits the Wall

Standard 3-axis CNC machines serve as the main tools in factories. They move along the X, Y, and Z directions. These machines work well for basic, box-like items. Yet, their weak points show up clearly with detailed designs.

Reliance on Multiple Setups: To shape all five working sides of a piece, workers must move and hold the part by hand several times. Each change brings chances for wrong positioning, built-up errors in sizes, and mistakes by people.

Accumulated Tolerance Issues: Small shifts in place during these steps can harm the full shape accuracy. As a result, it becomes hard to keep very strict size limits that medical or aerospace work requires.

Tool Length and Rigidity: The cutting part must stay straight to the face it works on. To get into deep spots, workers use long, slim tools. These tools bend easily and shake. So, this causes rough surfaces from shaking, and it forces slower speeds. In turn, this cuts down on both quality and speed of work.

Inability to Access Undercuts: Tricky spots like deep holes and sharp side walls often cannot be fully shaped without special holders. Such holders raise tool costs a lot and slow down the whole process.

The Power of 5-Axis: Defining the Extra Dimensions

5-axis CNC machining adds two extra turning axes, often called A, B, or C. These join the usual straight X, Y, and Z axes. So, this setup lets the cutting tool head or the work table tilt and turn at the same time.

This method has two main types.

3+2 Positional Machining (Indexed 5-Axis): The extra turning axes fix the part in one position. Then, the basic X, Y, and Z axes do the shaping. This cuts down the number of setups a great deal.

Continuous 5-Axis Machining: All five axes move together without stopping. This proves vital for shaping detailed, flowing surface shapes. Examples include impellers, turbine blades, or special medical covers.

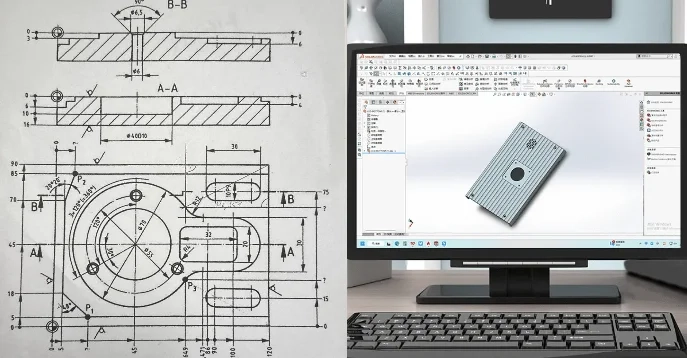

At XiHui Aluminium, our skills rest on these strong features. We use fast, modern 5-axis CNC tools. Also, we have skilled workers who know complex CAM programming well. They make sure the machine’s moves turn into solid shaping steps. This way, we keep accuracy high and cut down on time for the job.

Elevating Precision: Core Advantages for Custom Aluminum Projects

Switching to 5-axis methods brings real gains for custom aluminum items. It provides top-level exactness and solid build.

A. Single Setup, Unmatched Accuracy

The chance to reach up to five sides of a detailed custom aluminum part in one hold is the biggest plus. Skipping extra holds means the machine sets the links between all parts. It does not rely on hand adjustments. Thus, this keeps the final size limits as tight as possible. Such exactness matters for factory parts that need to fit right in assembly.

B. Optimized Tool Positioning and Finish

With 5-axis, the tool can angle just right to the cutting spot. This lets workers use shorter, wider, and stronger cutting tools. Shorter tools cut down on shaking and bending. As a result, they lead to better outcomes.

Tighter Tolerances: Steady cutting power helps control how material comes off with care.

Superior Surface Finish: Even cuts create smooth results. So, there is less need for extra finishing work after shaping. This lowers costs and speeds up delivery.

C. Machining Complex Geometries and Features

For plans that need deep spaces, detailed bends, or side features, 5-axis becomes a must. It lets the cutting part tilt to hit spots that were hard to reach before. Therefore, it makes possible several key tasks.

Complex Contouring: This works great for parts that handle fluid flow in high-use settings.

Deep Hole Drilling: Exact drilling and deep hole work—a key step next to turning and milling—happen with the best tool steadiness.

Integrated Processing and Efficiency

Our full range of services uses all CNC strengths.

Processing Technology: We blend CNC Turning for round parts, CNC Milling for flat or curved areas, and Drilling to make a full custom piece in one go.

Customization Capability: We focus on made-to-order work. We follow your technical drawings or samples closely. If you give a CAD file or a real sample, our smart CAM tools plan the best 5-axis path. This brings your exact design to life.

XiHui Aluminium: Your Partner from Profile to Part

As a solid aluminum profile manufacturer, XiHui Aluminium offers a full-chain edge that others rarely match. We oversee the aluminum profile quality right from the starting extrusion. This ensures strong material before it hits the machine.

Integrated Quality Control and Assurance

Our all-in-one method comes with tough checks on quality.

Strict Quality Detection: We use a firm, step-by-step check system. It covers material checks before shaping, size measures during work with CMM (Coordinate Measuring Machine) tools, and full reports at the end.

High Pass Rate: Our focus on exact tech and fine shaping methods leads to a very high rate of good parts. This cuts waste and keeps projects on time.

Post-Machining Surface Treatment: We provide a wide set of finishes. These include skilled steps like Anodizing for better rust protection and colors, Sandblasting for dull looks, and custom shine or brush work. All this meets your style and use needs fully.

Key Industry Applications and Experience

Our deep background in aluminum work leads to wins in tough fields.

Medical Devices: We make tight-tolerance aluminum cases for check machines and light, body-safe parts for surgery tools. Here, errors cannot happen.

Automotive/EV Components: We create detailed heat sinks, aluminum frame pieces, and special battery parts. These need a fine mix of low weight and strong build.

Electronics & Aerospace: We handle custom profile links, smart heat control items, and build parts. All meet strict rules on weight and sizes.

Partnering for Success: Cases and Support

Successful Cooperation Cases (Fictionalized Example)

We teamed up lately with a top robotics company to build a very detailed aluminum joint cover. The item needed more than 45 inside details, some deep-walled spaces, and a last size limit of $\pm 0.008$mm on the join faces. Using ongoing 5-axis milling, we cut the build time from an expected three weeks (with 3-axis and extra holders) to only five days. We hit 100% match on the first run. This sped up their test-to-full build schedule. It also showed the real worth of our full exact setup.

Dedicated Customer Support

We know that fast replies and clear talk matter in today’s build projects.

Quick Response & Design Optimization: Our engineer group stresses fast action. They give quick quotations and join in design-for-making tweaks early on. We spot ways to adjust your plan for better shaping and lower costs. Yet, we never cut function.

Efficient Sample and Batch Delivery: We focus on on-time sample delivery to speed your check process.

After-Sales Service and Quality Assurance: Our link lasts past delivery. We back our work fully. We offer wide after-sales support and a complete quality assurance promise on every part we make.

Conclusion

In today’s tough manufacturing world, sticking to 3-axis limits puts you behind. 5-axis CNC machining serves as the clear fix for custom aluminum parts that call for high detail, great surface quality, and full exactness.

XiHui Aluminium sits ready as your one-stop source. We mix the low costs and material watch of a focused aluminum profile maker with the skill of advanced 5-axis milling and turning. We aim not just to build parts, but to bring your bold engineering ideas to reality.

Set to raise your project’s exactness? Reach out to the XiHui team now. Talk about your custom 5-axis aluminum needs. And move forward to top manufacturing results.

FAQs

Q1: What is the typical tolerance XiHui Aluminium can hold with 5-axis CNC milling on aluminum?

A: We often reach size limits as tight as +0.005mm on detailed aluminum items. Our 5-axis skills keep this exactness across every part and angle.

Q2: Is 5-axis machining more expensive than 3-axis, and is it worth the cost?

A: The hourly rate for machine use might cost more. But 5-axis saves money in the end. It cuts setup time a lot, skips extra steps, and boosts exactness for detailed parts. This lowers waste and gets products out faster.

Q3: What types of aluminum alloys are best suited for 5-axis machining?

A: We often use strong types like Aluminum 6061 and 7075. They shape well and have good build traits. So, they fit high-exact 5-axis work in factory and car areas.