In today’s quick-moving industrial world, the need for storage options that are very flexible, long-lasting, and expandable is bigger than ever. Many fields, from logistics to healthcare, now often choose aluminum shelving systems. These systems can be adjusted for their particular work needs. Bulk custom aluminum shelving is a great choice. This is especially true for shelves improved with CNC punching, which creates exact rack uprights. What’s more, it gives a great mix of toughness, effectiveness, and versatility.

Carefully made storage systems do two things. First of all, they make handling stock more efficient. They also improve safety and the use of space. These systems help businesses make the best of their work processes by making sure that every part, from the shelves to the rack uprights, is made to very specific requirements.

Key Features of Bulk Custom Aluminum Shelving

Aluminum shelving systems are popular due to their unique material properties and flexible design. Let’s look at some of these key features in more detail.

Durability and Lightweight Nature of Aluminum

Aluminum has some big benefits. One of the main ones is its great strength-to-weight ratio. So, aluminum profiles are often used for industrial assembly lines. They are liked because they are lightweight and also nice-looking. Plus, they are simple to put together. This quality also lowers shipping fees and makes setup much easier.

Corrosion Resistance and Longevity

Aluminum creates a shielding oxide layer on its own. This layer fights off corrosion. When the surface is also treated with anodizing, it becomes extremely corrosion-resistant and resistant to wear. This makes it good for many different tough jobs.

Design Flexibility for Varied Applications

The modular nature of aluminum profiles is a key feature. It means they can be used in a wide variety of industries, as different profile sizes can be changed for different uses. It doesn’t matter what you need. It could be a small retail display or a strong warehouse racking system. Aluminum shelving can be adapted to meet different needs with custom profile shapes, sizes, and setups.

CNC Punching Technology in Aluminum Shelving Production

To get the high level of precision needed in today’s storage systems, CNC punching is very important in the manufacturing process.

Role of CNC Punching in Achieving Dimensional Accuracy

CNC punching is a big deal. It stands for Computer Numerical Control. This process makes sure every single hole or cut is made with perfect precision. This is very important for parts like rack uprights, where the inside measurements of the profile are vital for fitting together correctly and for the strength of the whole structure.

Benefits of Automated Fabrication Processes

Automation improves uniformity. It also lowers the chance of mistakes made by people during the making process. For instance, CNC punching promises exactly lined-up holes. This helps create tight connections and even weight spreading across all the units in a big order. This precision makes the best of the frame’s strength. As a result, the shelving units can hold up more weight without risk, and they won’t change shape or break.

Importance of Rack Uprights in Storage Systems

Rack uprights are very important. They are more than just vertical supports. In fact, they are the basic building blocks of any shelving system. Their main job is to give support for the weight above while linking the horizontal beams or shelves. The steadiness of these uprights decides the safety and capacity of the whole system. What’s more, when they are used with CNC-punched parts, they become even better at keeping the structure strong.

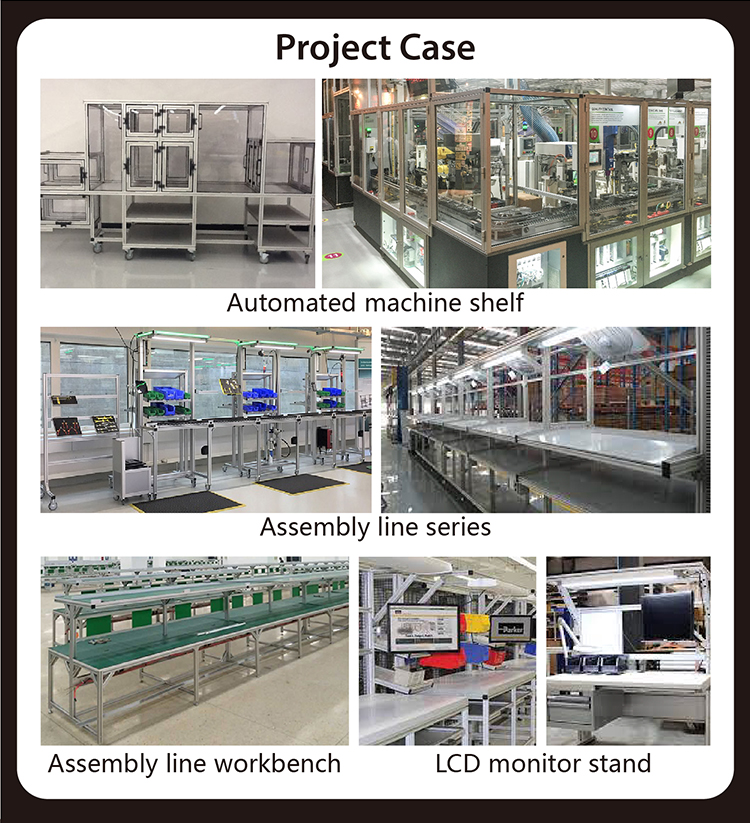

Applications Across Industries

The flexibility of custom aluminum shelving systems makes them good for many areas:

Warehouse and Logistics: Allows for neat arrangement and fast retrieval of inventory.

Commercial and Retail: Gives modern-looking, strong, and simple-to-change display systems.

Food Processing and Medical: Supplies clean, corrosion-resistant options for sanitary environments.

Electronics and Telecommunications: Gives non-magnetic materials with exact sizes for important equipment.

Customization Options in Aluminum Shelving Systems

One of the best things about aluminum is how much you can customize it.

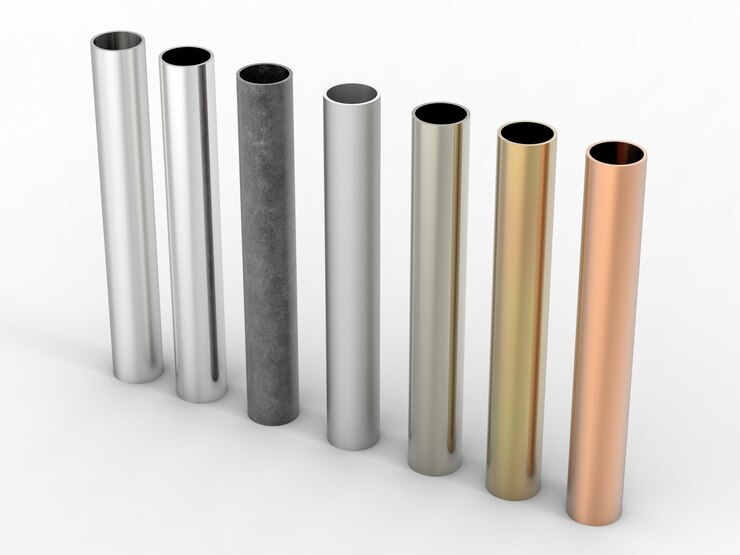

Profile Shapes, Sizes, and Surface Finishes

Customers can pick from many different cross-sectional shapes and popular metal mixes, such as the 3030, 4040, 6061, and 6063 series, based on how much weight the shelves need to hold.

Anodized, Powder Coated, and Polished Options

Different colors and surfaces can be chosen. These are possible through customizable anodizing, powder coating, and wood grain effects to fit any look or practical use you have in mind.

Modular Design Capabilities for Scalable Installations

Modular designs let businesses expand their storage setup without trouble. To help with this, our dedicated team of assembly engineers can provide assembly drawings and solutions based on what customers need.

XiHui Aluminium: Trusted Manufacturer of CNC Machined Aluminum Profiles

XiHui Aluminium has built a name as a trusted partner for providing custom aluminum solutions in large amounts. With 33 years of production and sales experience, our factory runs 15 extrusion lines and 40 deep processing machines. We also have a library of tens of thousands of molds and a wide variety of design styles, which allows for a yearly production of more than 20,000 tons.

XiHui is an expert in very exact machine work—including milling, turning, bending, and welding—with accuracy down to ±0.01mm. All products are made following ISO 9001-certified quality control rules. As a top choice for a worldwide provider, XiHui offers OEM/ODM services to over 120 countries.

Quality Control and Production Efficiency

From start to finish, XiHui keeps strict rules. Our own engineering team works closely with customers to see if a design can work, and we can assist clients in sourcing necessary accessories to complete their projects. All our surface finishes meet top-level national rules, such as GB/T 5237-2008.

Advantages of Choosing Bulk Orders for Custom Shelving Projects

Ordering in bulk gives you both money-saving and shipping-related benefits. Making things in big batches lowers the price for each item. We can make up to 5,000 tons in a month, so customers can rely on on-time shipping for their big jobs.

FAQs:

Q1: What makes rack uprights necessary in aluminum shelving systems?

A: Rack uprights act as the main vertical supports that make sure the system is steady. When they are made with CNC punching, they promise an exact lineup. This creates balanced weight spreading and keeps the whole shelving system strong.

Q2: Can I change the color or finish on my aluminum shelves?

A: Yes! XiHui Aluminium gives you many ways to finish the surface. These include anodizing (in silver or black, for example), powder coating (like in white or black), sandblasting, and polishing. We can even do custom wood grain effects to fit your particular look or use.

Q3: How quickly can bulk orders be sent out?

A: Delivery times depend on the type of order. First of all, things we have ready can usually be sent within 3–5 days. For custom bulk orders, the waiting time for a full container is about 25–30 days. And if a new mold is needed, it will take an extra 7–15 days for us to make it.