As different industries work to improve their products, making them lighter and smaller, accurate aluminum machining has become a very important factor. From airplane parts to everyday electronics, makers now need parts with very exact measurements and extremely thin walls. These needs have pushed CNC machining technology forward. As a result, it is now possible to produce ultra-thin aluminum parts with great speed and correctness.

Why Thin-Wall CNC machining Matters

Thin-wall CNC machining is a crucial process. It is especially needed for uses where you need to use material well, handle heat effectively, and keep the part strong, all within a small design. We can make aluminum parts with walls as thin as 0.4mm. This ability lets engineers follow very strict design rules. It also helps them reduce a product’s final weight as much as possible. This is a major benefit in fields like the automotive industry, aerospace, and modern robotics.

The Technical Challenge: Precision at 0.4mm Thickness

Getting dependable results with walls that are less than a millimeter thick is a difficult engineering task. It needs a perfect mix of top-tier machines, smart planning, and high-quality materials.

Overcoming Key Machining Difficulties

Machining thin walls brings up several complex problems. For example, the material is not very rigid. This low stiffness makes it likely to vibrate during the milling process, a problem known as chatter. This vibration can damage the surface quality and hurt the part’s accuracy. Also, high-speed cutting creates a lot of heat. This heat buildup can cause the material to expand, which leads to problems with its final size. On top of that, if the part is not held securely or if the tool pushes too hard, the delicate part can easily bend or get twisted. To beat these challenges, we must use special holding methods and carefully planned tool paths. A deep knowledge of how materials behave is also necessary.

Choosing the Right Materials and Alloys

Not every type of aluminum is a good fit for this difficult job. The 6000 series is frequently chosen because it offers a great mix of machinability, strength, and ability to transfer heat.

6061-T6: This type offers superior strength. This quality makes it a great choice for thin-walled parts that need to be structurally sound.

6063-T5: This type provides a truly exceptional surface finish. This feature is perfect for parts where looks are important, such as in architecture.

These aluminum types are popular because they resist rust very well. They also perform dependably even when being machined at high speeds.

High-Speed Fabrication: The Key to Efficiency and Precision

To keep up with worldwide demand, makers must combine exactness with speed. This is done through advanced high-speed machining, or HSM, strategies.

The Principles of High-Speed Machining (HSM)

HSM uses spindles that spin at very high speeds along with fast, controlled movements. This method works very well for thin-walled aluminum parts. This is because it shortens the time the cutting tool is in contact with the material. As a result, there are fewer cutting forces and less heat is transferred into the part. This also lowers the chance of the part bending. All of this happens while material is removed at a very quick rate.

The Importance of Proper Tooling and Calibration

Success with thin-wall machining is not possible if you don’t have the correct tools. We use micro-grain carbide end mills that have very sharp cutting edges. They also have special coatings that help lower friction and reduce cutting forces. Furthermore, our CNC machines go through regular, tough calibration checks. We use tools like laser interferometry and ball-bar testing. These tests make sure the machine’s positioning stays perfect. This guarantees that all parts are made with the same high quality, even during long production runs.

Applications: Where Thin-Wall Machining Delivers Value

When standard, ready-made parts are not good enough, custom CNC machining becomes a vital service. It is needed to make detailed shapes designed for specific industry purposes.

- Aerospace and Aviation:Parts that are both lightweight and strong are a basic need in this field. We have the skill to machine parts down to 0.4mm. This ability allows our clients to meet the very strict weight-to-strength goals needed for flight-critical parts, drones, and satellite systems.

- Consumer Electronics:Smaller devices need accurate cases that keep their internal electronics safe. These cases also need to let heat escape effectively. Our methods create very slim, tough casings. We also apply anodized finishes that improve the look and prevent rust.

- Automotive Lightweighting:There is a growing focus on saving fuel and making electric cars go farther. Because of this, car makers increasingly use thin-wall aluminum parts. These parts help lower the vehicle’s weight in areas like battery cases and frame parts without giving up safety or toughness.

Quality Control for Sub-Millimeter Precision

Careful quality assurance is extremely important when you are working with such small measurements. Every single part made at 0.4mm goes through an inspection process with many steps. This includes checks with a Coordinate Measuring Machine (CMM) and with optical measurement tools. These systems can spot tiny differences from the original design specifications. We check the final size, tolerances, and the smoothness of the surface. This ensures every part meets global standards before it is packed. After inspection, parts are placed in custom, anti-static foam holders to make sure they are delivered safely anywhere in the world.

XiHui Aluminium: Your Partner for Advanced CNC Projects

XiHui Aluminium is a special company, not just for our technical skill, but also for our all-in-one abilities that make the whole production process smoother.

A Vertically Integrated Process

With more than thirty years of experience, we have put a lot of resources into research, modern machinery, and the skills needed for making ultra-thin parts. Unlike suppliers that send out important work to other companies, we handle the entire process in our own facilities. This starts with making custom extrusion dies from a client’s drawings right here in our workshop. After that, the profiles are sent to our 15 extrusion lines. Then, they go to our 40 advanced CNC machining lines for all the secondary work. Lastly, we manage anodizing and other surface finishing processes ourselves.

Experience and Global Trust

This total control means the workflow is smooth. It also leads to faster delivery times and steady, reliable quality from the beginning to the end. Our large scale and deep knowledge have made us a dependable manufacturing partner for customers in more than 120 countries.

Frequently Asked Questions (FAQs)

Q1: How does custom CNC machining benefit my product development?

A: Custom CNC machining gives you complete design freedom. It lets you create complex parts that are made exactly for your project’s shape and needs. You are not held back by standard sizes. This is perfect for making prototypes quickly, improving designs, and creating high-quality final parts.

Q2: What are the minimum order quantities (MOQs) for custom projects?

A: Our MOQ is set up to be flexible for projects of different sizes. For parts that need an anodized finish, the MOQ is 500 kg for each model. For parts needing powder-coated or wood grain finishes, the MOQ is 2,000 kg (which is 2 tons) for each color.

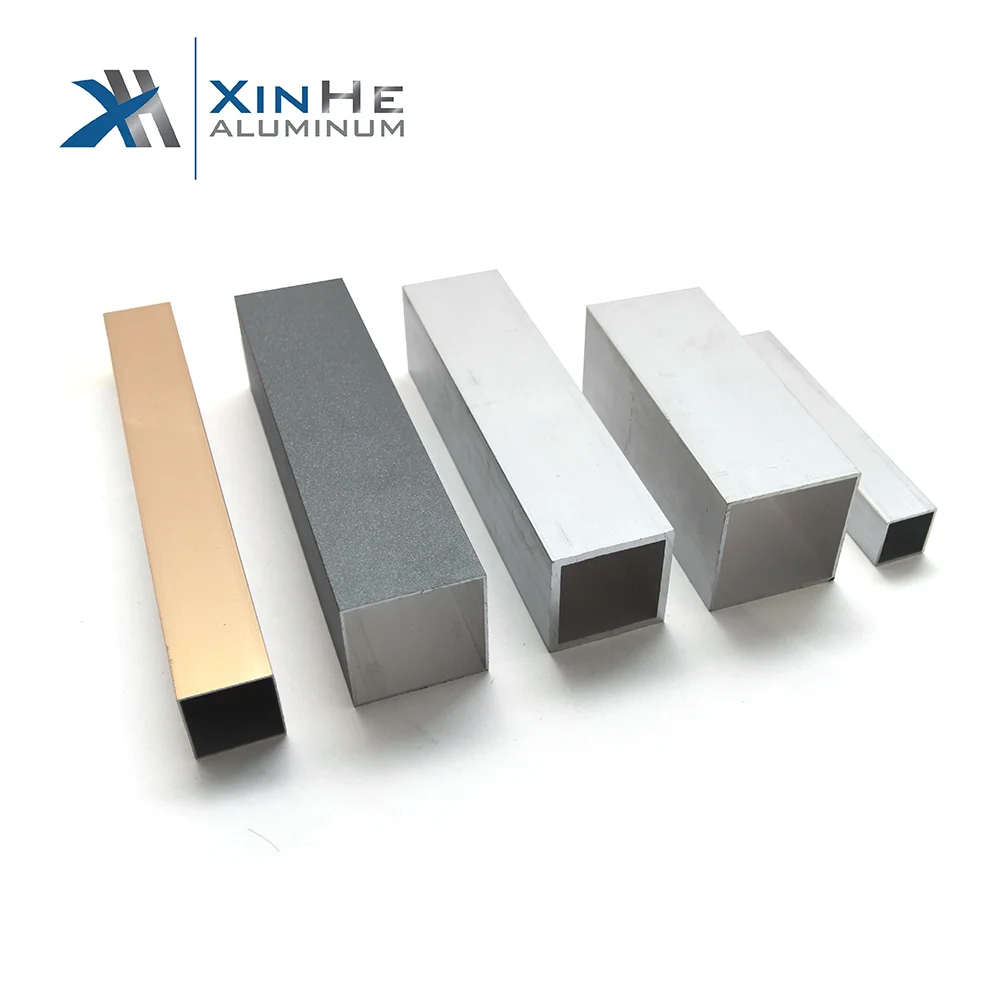

Q3: What surface treatments are available for thin-wall aluminum parts?

A: We provide a large selection of finishes to meet both practical and visual needs. This includes anodizing (in silver-white, black, and other custom colors), powder coating, and different mechanical finishes like polishing and sandblasting.