As lightweight performance materials keep gaining ground in aerospace, automotive, and electronics fields, custom CNC machining of aluminum extrusions stands out as a key element in today’s manufacturing world. The growing need for parts that save weight yet hold up strong pushes forward new ideas in handling aluminum profiles.

CNC machining lets makers shape tricky forms and add exact details to extruded shapes. This way, they fit the exact needs for power, closeness in size, and lasting quality in specific uses. Such work proves especially important in tough areas where detailed designs meet heavy-duty tasks. Manufacturers can create parts that perform well under pressure, and this approach helps meet strict standards in demanding environments.

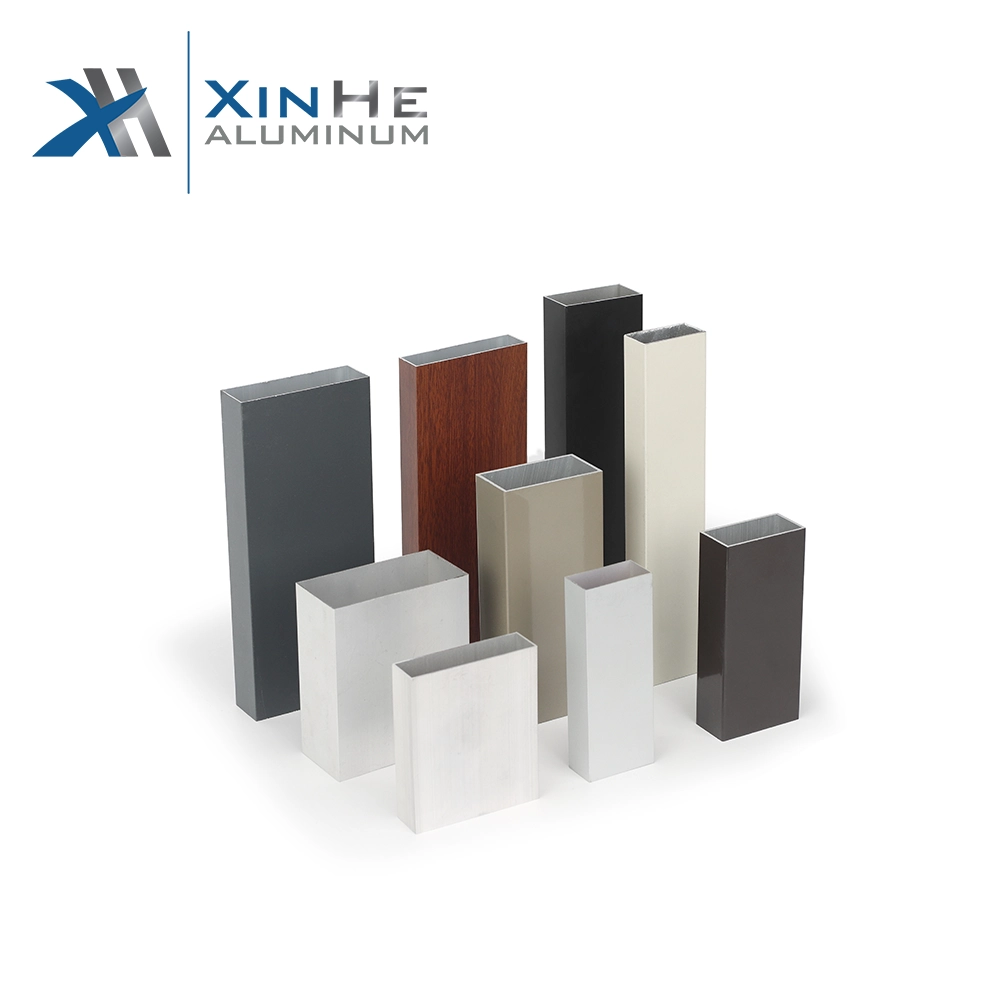

Aluminum extrusion profiles, above all those for building purposes, need to stay tough. At the same time, they should be small and fight off rust well. Businesses now lean toward made-to-order options. These match their needs for how things work, the surroundings they face, and even how they look.

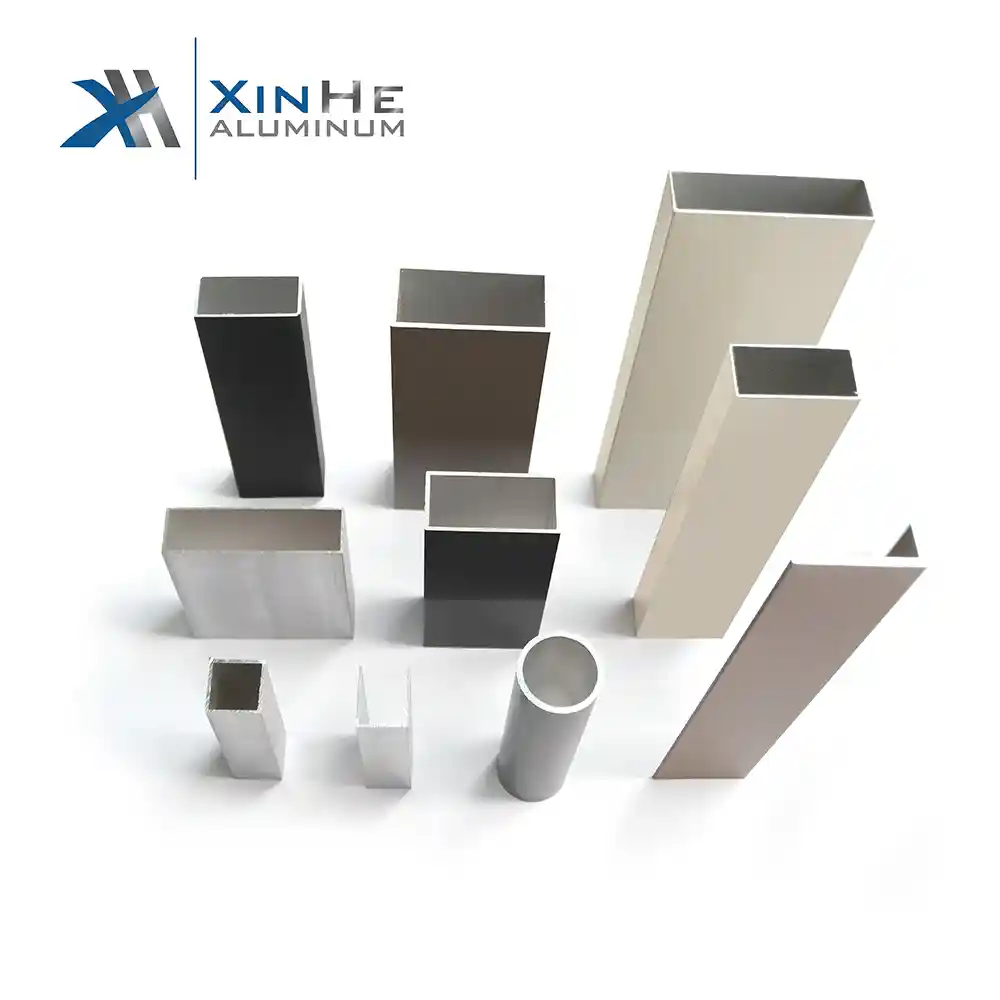

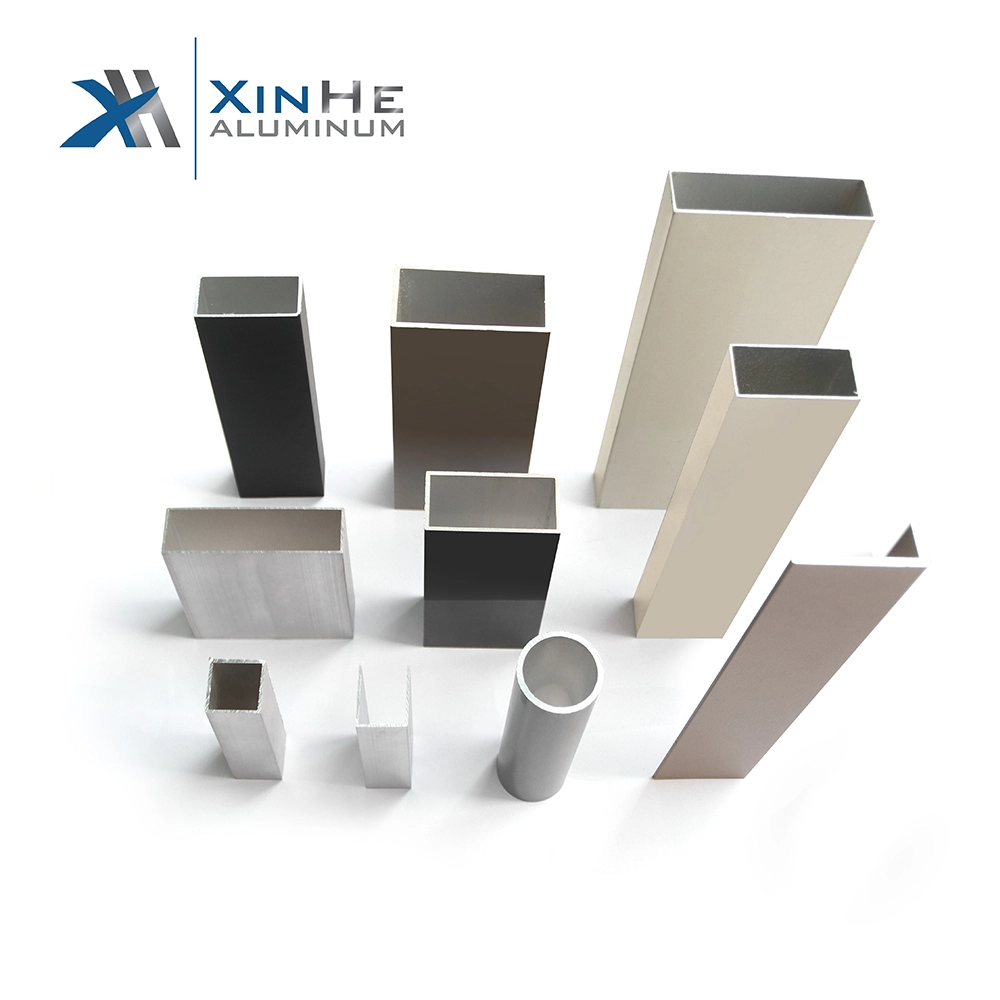

Xihui Aluminium provides carefully made CNC-machined aluminum profiles. They build these for key industries that need top performance. The company mixes smart CNC machining with tolerances of ±0.01mm. They use strong alloys like 6061 and 7075 from aerospace. Plus, they offer full services from quick models to final surface work.

What Material Factors Determine the Strength of an Aluminum Extrusion Profile?

The type of alloy chosen plays a big role in how much pull the aluminum extrusion profiles can take, their point of bending before breaking, and their hardness. Take 6061 and 7075 alloys, for instance. They give good strength and hold up against repeated stress, so they suit parts that carry weight or matter for safety.

The temper label, like T5 or T6, shows the heat process the alloy went through. T6 temper means heating to dissolve elements, then cooling and aging slowly. This builds strength by forming tiny hard spots in the metal. As a result, the material gets tougher overall, and it works well in many setups. Common materials: 3030, 4040, 4545, 5050, 6060, 6061, 6063; Temper: T5, T6.

How Does Grain Structure Influence Mechanical Integrity?

Aluminum with small, even grains stays steadier. It also resists wear from constant use better. Makers control the cooling right after extrusion to make grains finer. This boosts how the material handles forces without losing its bendability. In practice, this means parts last longer in real-world stress. By watching cooling speeds closely, companies steer clear of big grains that create soft spots. Even features throughout the metal help keep power steady over long pieces of profile. Therefore, the whole structure holds together reliably.

Why Should Impurity Control Not Be Overlooked?

Small amounts of unwanted bits or rough spots in the metal can harm how well it bends or holds shape. Keeping these low during the melting stage raises flexibility and the force it takes to deform. Clean processes lead to better overall results in use.

Our ISO 9001-certified processes ensure durable, lightweight components with superior corrosion resistance and thermal conductivity, supporting applications that demand both reliability and longevity. This focus helps build trust in the final products for various fields.

Which Process Parameters Most Affect the Strength of Extruded Profiles?

The heat level during extrusion needs careful setting to let the metal flow properly. Too much heat might lead to rust on the outside or empty spots inside. In the same way, keeping speed in check stops rips or breaks by spreading force evenly through the tool. Proper balance here ensures smooth output every time.

How Does Die Design Enhance Profile Strength?

The shape of the die shapes how stress spreads in the finished profile. Soft curves, even thicknesses in walls, and easy shifts cut down on high-pressure areas. This design choice makes the part less likely to fail under load. Checking the die condition often keeps the form and size steady in big batches. That matters a lot for making profiles that fit tight measures. Over time, this practice maintains quality across runs.

Why Is Cooling Strategy Post-Extrusion Important?

Quick cooling after extrusion locks in the good inner structure from the hot shaping. Choices like air or water depend on the metal type and what the part will do. This step preserves the benefits gained earlier. Even cooling cuts leftover tensions that could twist the shape or cause early breaks in action. By handling this well, makers avoid common issues and extend part life.

How Can Post-processing Enhance Strength and Durability?

Heating to mix elements evenly into the base metal is solution treatment. After that, slow aging creates hard particles. This hardening method lifts the force needed to bend 6xxx and 7xxx series alloys. It strengthens without extra bulk, which fits goals in air travel and moving vehicles perfectly. Such treatments make the profile stronger without adding weight—a primary goal in aerospace and transport applications. Engineers value this for keeping designs light yet capable.

What Surface Treatments Maintain Strength While Improving Durability?

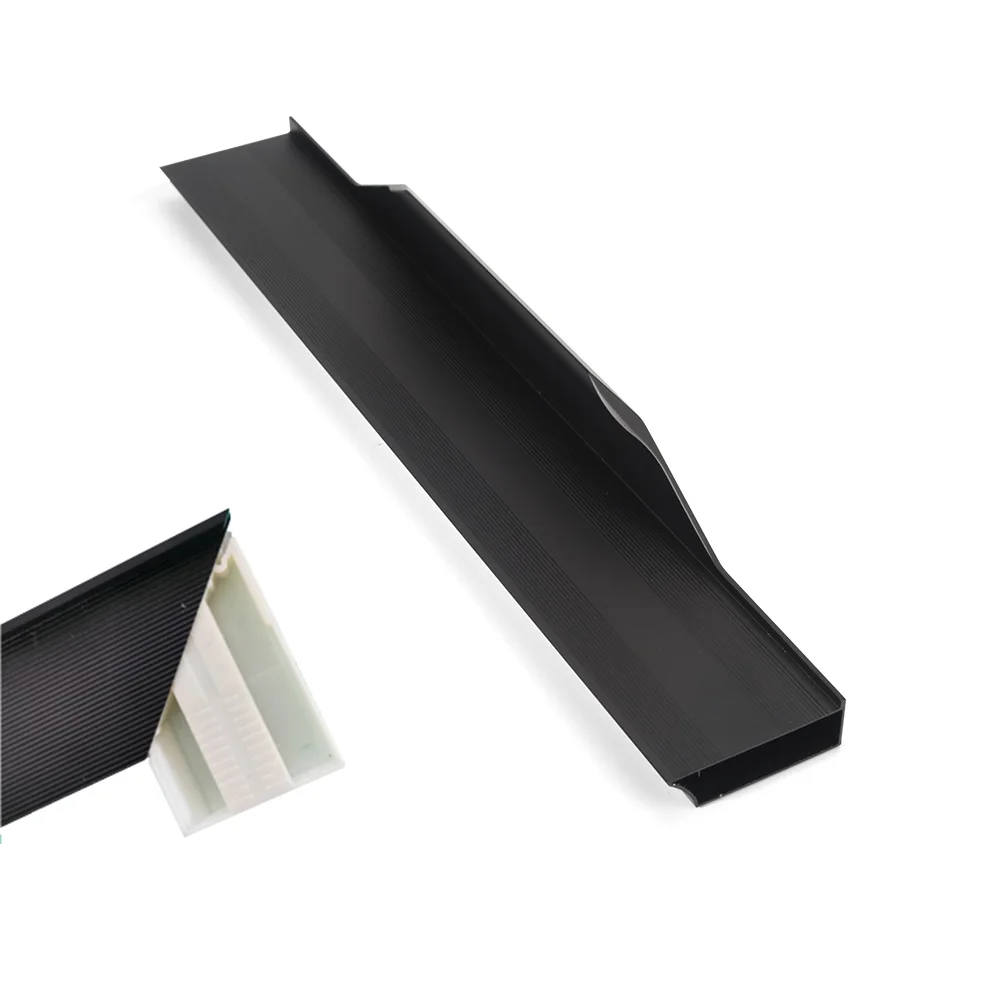

- Anodizing boosts protection against rust by building a tough outer layer. It keeps the inner strength intact.

- Powder coating gives better bump resistance and shields from the weather. It hardly touches the core power at all.

What Design Strategies Help Maximize Aluminum Profile Strength?

Thicker sections and added supports like ribs raise the resistance to bending. Balanced shapes spread weight around to skip hot spots of stress. This setup handles twists better, too. Designs with multiple hollow parts or box forms add twist strength without much added mass. They work well in setups needing a firm hold.

How Can Weight-to-Strength Ratio Be Optimized?

Hollow areas with inside braces or thickeners let builders cut weight while keeping a solid build. This idea shines in light design work. For example, T-slot extrusions in factory tools mix easy changes with good power. They allow setups that adapt yet stay strong.

How Does CNC Machining Preserve or Improve Structural Integrity?

Extrusion sets the main outline of a profile. But CNC machining adjusts key spots like screw openings, joint faces, or fix points. It hits the size accuracy of ±0.01mm. Best of all, it leaves the material’s base qualities untouched. This step refines the part for an exact fit in assemblies.

What CNC Operations Are Commonly Used on Aluminum Extrusions?

- Milling: Allows exact cuts and outlines for custom shapes.

- Drilling & tapping: Prepares spots for bolts and screws securely.

- Turning: Handles round or tube-like parts smoothly.

- Engraving & deburring: Cleans edges and adds marks for looks and safety.

- You can explore one such advanced offering here: Metal Parts 3D Printing Machining Parts.

Who Offers Industry-Leading Custom CNC Machining for Aluminum Extrusions?

If you seek a solid teammate for CNC work on aluminum that covers idea help, test builds, finish touches, and large runs, then Xihui Aluminium shines bright. They bring deep know-how from more than 30 years in the game. Their yearly production capacity reaches 20,000 tons, serving buyers worldwide with parts built just right for high-stakes areas.

The firm runs 15 extrusion setups, over 40 CNC tools, including 5-axis ones, and special lines for anodizing plus powder coating. We are an aluminium manufacturer located in Foshan with more than 31 years of experience since 1993. This setup allows them to handle complex orders from start to end efficiently.

Their skills cover airframe supports, car frame pieces, box cases for tech that manage heat, and health tool components. All follow ISO 9001 rules for quality. You can also view their high-precision offering here: Custom Industrial 5 Axis CNC Milling Turning Aluminum.

FAQ

Q1: What is the strongest aluminum extrusion alloy available?

A1: Among commonly used alloys, 7075-T6 is considered the strongest due to its high tensile strength (~570 MPa), but it is less corrosion-resistant than 6061-T6 or 6063-T6.

Q2: Does CNC machining weaken an aluminum extrusion profile?

A2: When performed correctly with appropriate feeds and speeds, CNC machining does not compromise the profile’s strength. Skilled operation ensures the part stays as robust as before, sometimes even better fitted for its role.

Q3: Can I request customized shapes and surface finishes for my extruded profile?

A3: Yes. With a minimum order quantity of just 500kg per design for anodizing and 2 tons for powder coating or wood grain finishes, you can fully customize geometry, dimensions, and colors to match your application needs.