In the realm of custom CNC machining, saving money is a major goal for engineers, designers, and builders. Every choice in the design process can greatly affect the total cost of making parts, especially when using materials like aluminum. By using Design for Manufacturability (DFM) ideas early on, teams can improve their parts for both performance and affordability.

Aluminum is a top choice for CNC machining because it’s easy to work with, light, resistant to rust, and budget-friendly. Its flexibility makes it perfect for many uses, from airplane parts to building designs. However, even with a material as great as aluminum, poor design decisions can increase machining time, wear out tools, and waste materials. That’s where DFM helps. It connects design choices to real cost factors like machining time, tool expenses, and setup fees. Here are five DFM tips to cut costs significantly.

1. Improve Wall Thickness and Shape Design

When creating aluminum parts for CNC machining, the thickness of walls is key for strength and ease of production. Thin walls can cause problems. They may shake or bend during machining. This forces workers to slow down the cutting process to avoid damage. As a result, machining time increases, which raises costs for each part. A good guideline is to keep walls at least 1 mm thick for aluminum.

Also, smart shape design can reduce tool wear and save time. For example, adding larger rounded corners inside parts lets workers use standard tools. This avoids the need for costly special tools or slow extra steps. These simple changes lower both tool and production expenses.

2. Simplify Part Design to Reduce Complexity

Complicated shapes often need multiple setups or special tools. Both of these increase CNC machining costs. One smart DFM approach is to avoid undercuts when possible. Undercuts may require custom tools or expensive extra processes like EDM, which add to costs.

Another way to make production easier is to design parts that need fewer setups. Each setup requires workers to stop and adjust the machine. This adds to labor and operating costs. For example, try to place all machined features on just one or two sides of the part. A part machined from one or two setups is always cheaper than one needing five or six.

3. Use Standard Tolerances When Possible

High precision is expensive. Tight tolerances mean more inspection and slower production. So, ask yourself: when are tight tolerances really needed?

Tight tolerances require slower cutting speeds. They also need multiple finishing steps. This greatly increases machining time. Plus, they demand careful inspections with tools like a CMM (Coordinate Measuring Machine), which takes more time. Only use tight tolerances for critical features that affect how the part works or fits together. For less important areas, looser tolerances are fine. They help cut both inspection and machining costs.

4. Pick the Right Aluminum Type for Your Project

Choosing the right material affects how easy it is to machine and the total cost. A strong type like 7075 costs more to buy. It’s also harder, so it takes longer to machine and wears out tools faster compared to an easier type like 6061.

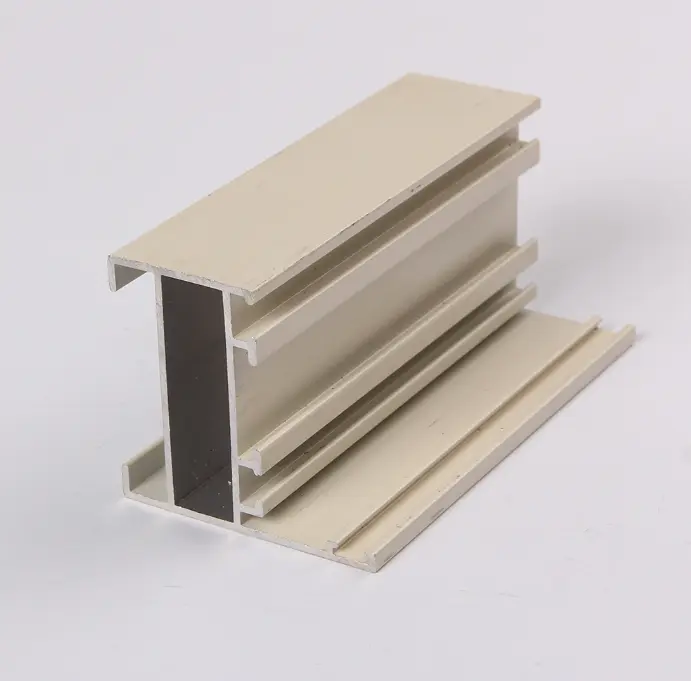

Two common types for CNC projects are 6061-T6 and 6063-T5/T6. Generally, 6061 is stronger and great for machining. Meanwhile, 6063 is softer, making it ideal for complex shapes or when a smooth surface is important. If you plan to add a finish like anodizing, choosing a type like 6063 will give better results and lower finishing costs.

5. Reduce Unnecessary Decorative Features

Looks are important, but decorative features should be carefully considered. Every line in a design means more machine movement. A detailed logo or pattern that takes an hour to carve adds that hour’s cost to every part.

Instead of carving complex details, consider adding finishes like anodizing or powder coating after machining. These are more affordable ways to improve appearance. For example, XiHui Aluminium offers finishes like anodized silver or electrophoresis champagne. These enhance looks without high CNC costs.

Brief Overview of XiHui Aluminium

Founded in 1993, Foshan XiHui Aluminium Co., Ltd is a reliable name in aluminum extrusion and production. They handle everything from extrusion molding to anodizing, powder coating, deep CNC machining, and full ODM/OEM support. This all-in-one approach ensures high quality at every step.

Their products range from window frames to custom industrial T-slot profiles for automation systems. They have thousands of mold designs ready for quick use. They also provide free assembly advice through their skilled team.

Conclusion

To lower custom CNC machining costs without losing quality, keep these key ideas in mind:

- Keep walls at the right thickness.

- Avoid complex shapes and multiple setups.

- Use looser tolerances when possible.

- Choose aluminum types based on performance and finish needs.

- Cut out non-essential decorative features.

Working with an experienced company like XiHui Aluminium ensures you gain from years of knowledge. With quick delivery and flexible order sizes, they support projects from small prototypes to large production runs.

FAQs

Q1: What is the minimum order quantity (MOQ) at XiHui Aluminium?

A: The MOQ depends on the product. For custom aluminum profiles, it’s 500 kg per design. If you need a specific color like powder coating, the MOQ is 2 tons per color. For custom CNC machined parts, the MOQ starts at 100 pieces.

Q2: Can I request free samples before placing a bulk order?

A: Yes, XiHui Aluminium offers samples before large orders. This lets customers check sizes, surface quality, and fit before committing to big volumes.

Q3: What aluminum types does XiHui Aluminium commonly use for CNC machining?

A: They often use 6061-T6 and 6063-T5/T6. These provide a great balance of machinability and strength, making them suitable for structural parts and decorative finishes like anodizing or powder coating.