Running a business means finding parts that are both great and affordable. At XiHui Aluminium, we focus on customized aluminum alloy CNC processing. We make parts that balance quality and cost perfectly. Whether you work in aerospace, automotive, or electronics, you want components that work well and don’t cost too much. In this blog, we’ll show you how we create valuable products, keep prices low, and ensure quality stays high. Let’s see why our approach at XiHui Aluminium is the best choice for your next project.

Overview of Customized Aluminum Alloy CNC Processing

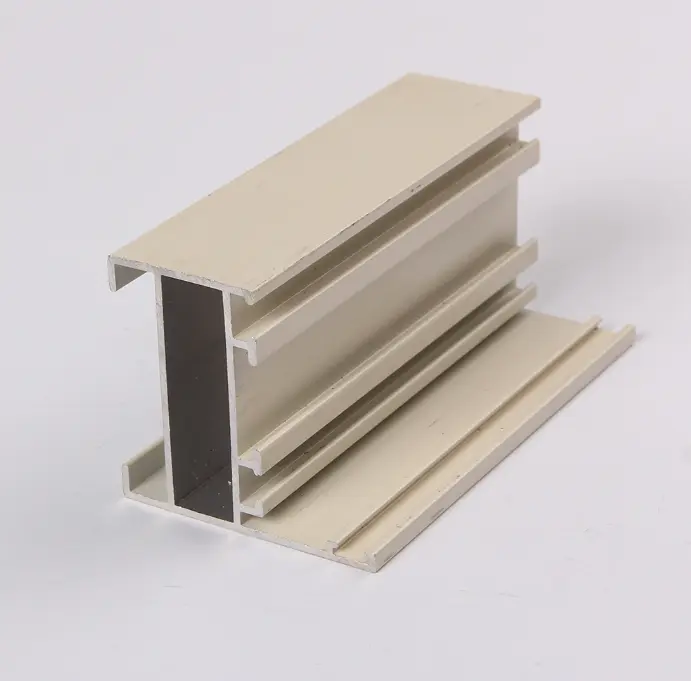

CNC machining is like a skilled craftsman shaping aluminum alloys into exactly what you need. It uses computer-controlled tools to cut and form parts with great accuracy. At XiHui Aluminium, we customize alloys like 6061 and 6063. These are strong, light, and don’t rust easily. This makes them perfect for industries where performance matters. Our process handles everything from single prototypes to big batches. All are made to fit your needs. With our custom CNC aluminum profiles, you get parts that match your project perfectly.

Balancing Quality and Cost in CNC Processing

The challenge in manufacturing is making excellent parts without high costs. We’ve mastered this at XiHui Aluminium. We focus on both quality and savings. Here’s how we do it:

Strategies to Maintain High Product Quality

Precision Techniques in CNC Machining

Accuracy is key. Our CNC machines achieve very tight accuracy levels, as small as ±0.01mm. This means your parts meet your exact requirements. For example, in aerospace, where details are critical, our accuracy ensures parts work perfectly.

Use of Advanced Equipment and Technology

We use modern 5-axis CNC machines. They shape parts from multiple angles at once. This improves accuracy and speed. We also use smart software to check quality as we work. Our custom industrial 5-axis CNC milling parts show how technology keeps quality high.

Methods to Reduce Costs Without Compromising Quality

Efficient Material Usage

We treat aluminum like a valuable resource. Our software plans cuts carefully. It’s like solving a puzzle to use every piece. This cuts waste by up to 20%. As a result, we save money without lowering quality. This works well for projects like our large CNC machining services.

Streamlining Production Processes

Time saves money. We use automatic programming to speed up setups. Real-time checks catch problems early. This avoids wasted resources. So, we deliver your OEM CNC milling and turning parts faster and cheaper.

| Strategy | Benefit |

| Accurate Machining | Parts meet exact needs, no mistakes |

| Modern Equipment | Quicker, more accurate production |

| Smart Material Use | Less waste, lower material costs |

| Streamlined Processes | Faster delivery, reduced labor costs |

Creating High-Value Products Through Customized CNC Processing

Valuable products perform well and save you money over time. Here’s how we make that happen:

Enhancing Product Value with Tailored Solutions

Customization is our strength. Picture needing a special part for a new device. We work with you to design and make it. We ensure it’s both useful and strong. Our metal casting and 3D printing machining parts are made to improve your product’s performance, whether for electronics or heavy machines.

Delivering Cost-Effective Solutions for Customers

We keep prices low by being smart about materials and processes. For example, we recycle aluminum scraps. This cuts costs and helps the environment. Buying materials in large amounts also gets us better prices. As a result, you pay less. These savings make our parts a great value while keeping quality high.

XiHui Aluminium: A Reliable Customized Aluminum Alloy CNC Supplier

We’re proud to be a trusted name in CNC processing. Here’s why businesses pick us:

Company Background and Expertise in Aluminum Alloy CNC Processing

At XiHui Aluminium, we’ve spent years perfecting aluminum alloy machining. Our experience (as seen on our About Us page) covers industries like medical, automotive, and construction. From small prototypes to huge orders, we deliver with care and accuracy.

Commitment to Quality and Cost Efficiency

Quality is our priority. We follow strict ISO 9001 standards. We check every part for accuracy and strength. At the same time, we keep costs low with smart technology and efficient workflows. Our extruded aluminum alloy profiles show how we balance both.

- Quality Focus: Careful checks and modern tools ensure perfect parts.

- Cost Savings: Bulk buying and less waste keep prices low.

- Customer First: We listen to your needs and provide custom solutions.

Conclusion: Achieving the Perfect Balance Between Quality and Cost

Customized aluminum alloy CNC processing gives you quality and savings in one package. At XiHui Aluminium, we use advanced tools and cost-saving methods to deliver great products. Whether you’re building planes, cars, or electronics, we’ve got parts that perform and fit your budget. Ready to start your project? Contact us today to bring your ideas to life.

Frequently Asked Questions (FAQs)

Q1 What are the benefits of using aluminum alloys in CNC processing?

A1 Aluminum alloys are light, strong, and resist rust. They’re great for industries like aerospace and automotive, where weight and strength are key. They also transfer heat well, which is ideal for electronics. Our CNC process ensures these benefits shine through with accurate, custom parts.

Q2 How does customization impact the cost-effectiveness of CNC machining?

A2 Customization lets us make parts that fit your exact needs. This reduces waste and extra costs. By designing only what you need, we avoid making too much. Our efficient processes and recycling further lower prices. So, you get valuable parts at a good price.

Q3 Why choose XiHui Aluminium for customized aluminum alloy CNC processing?

A3 We offer great skills, quality, and affordability. Our modern 5-axis CNC machines and ISO 9001 standards ensure excellent parts. We keep costs low with smart material use and efficient processes. At XiHui Aluminium, we work closely with you to deliver what your project needs.