In today’s fast-moving industrial world, the need for custom CNC machining in aluminum alloy projects has grown a lot. As industries change and product designs get more detailed, companies want parts that fit exact needs. Custom CNC machining creates complex aluminum shapes made just for specific projects. These shapes ensure parts work well, are strong, and look good.

Precision and Customization in CNC Machining

Accuracy and custom designs are key in modern manufacturing. In fields like aerospace, automotive, or electronics, even tiny mistakes in part sizes can cause problems or failures during assembly. Custom CNC solutions fix this by making parts that match design plans or sample pieces perfectly.

These tailored CNC services improve how parts work together. They also make production faster by cutting down on extra work after machining. Plus, they reduce wasted materials. This means every part helps the final product perform at its best.

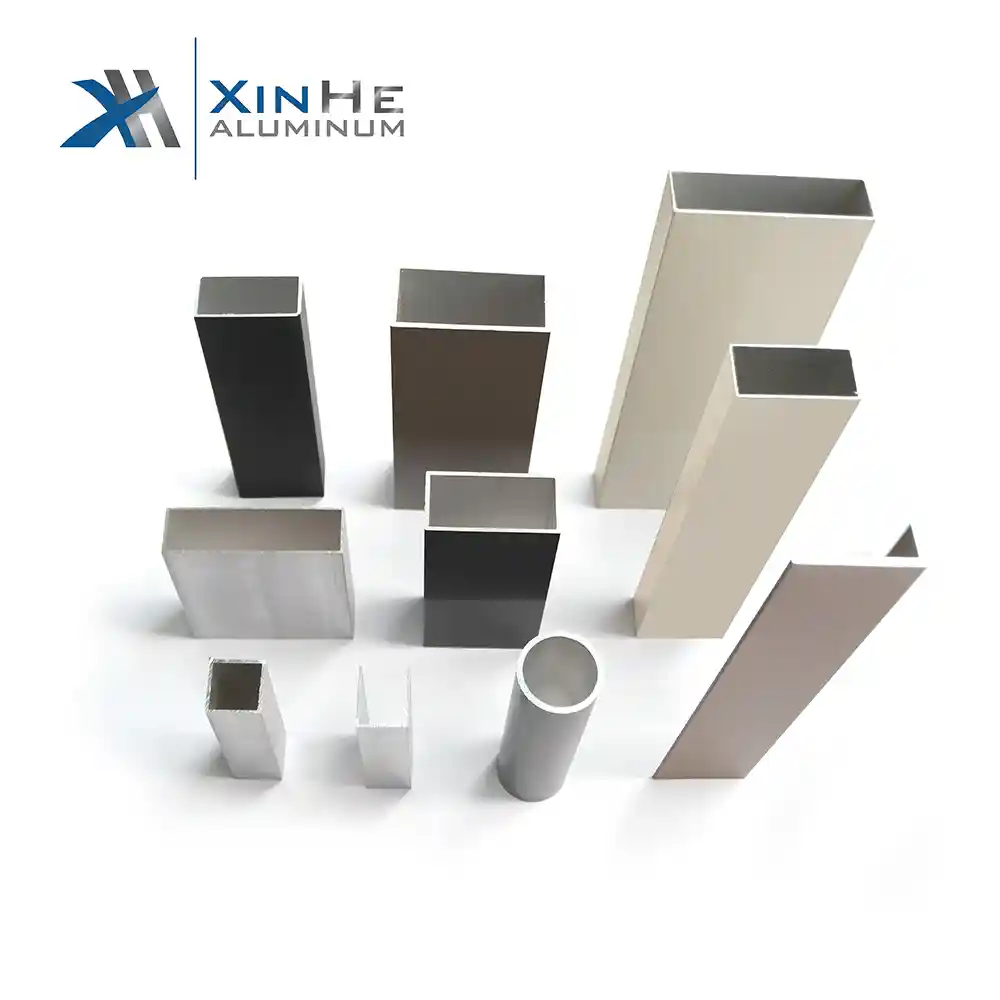

XiHui Aluminium: Trusted Maker of Aluminum Shapes

XiHui Aluminium is a dependable partner for custom aluminum shape manufacturing. Started with a focus on quality and new ideas, Xihui Group has been a professional maker of aluminum shapes for over 20 years. The company has become a leader by investing in modern tools and improving its processes.

Xihui Aluminium has 22 extrusion lines, ranging from 500T to 3600T. It also offers full processing services like cutting, drilling, tapping, milling, welding, bending, stamping, and CNC machining. This setup lets the company control quality and deliver on time.

The company sends products to over 50 countries, including Germany, Italy, Brazil, India, and South Korea. This global reach shows Xihui Aluminium’s experience in exports and strong ties with clients in many markets.

Xihui Aluminium’s commitment to new ideas shines through in its high standards. All products meet GB/T 5237-2008 rules, ensuring they perform well in various uses.

Technical Strengths Behind Custom CNC Machining at XiHui Aluminium

Xihui Aluminium uses top-notch tools and skilled workers to deliver precise custom parts. It has advanced CNC machining centers. These machines work fast and with great accuracy. They can move in multiple directions to create complex shapes that older methods can’t handle.

The team is just as important. Xihui Aluminium employs skilled workers with years of experience in aluminum processing. Their knowledge ensures every project gets careful attention, from early designs to large-scale production.

By controlling cutting paths and tool movements precisely, Xihui Aluminium makes parts with tight measurements. These are crucial for systems like robotics or aerospace, where accuracy matters most.

Tailored Solutions Based on Client Needs

Xihui Aluminium focuses on customers by offering solutions made for specific projects. It accepts designs or sample pieces from clients. This flexibility helps turn ideas into real parts without changes. Whether it’s a unique shape or detailed hole patterns, Xihui Aluminium creates parts that meet client goals. Production can handle small batches for testing or large orders for full manufacturing. This makes it cost-effective for any project size.

The engineering team works closely with clients during design. They study how parts will handle stress and suggest improvements. These changes boost performance while keeping parts easy to make. As a result, every piece fits perfectly in its intended use.

Strict Quality Control Process Ensuring High Standards

Quality is at the heart of Xihui Aluminium’s work. The company checks quality at every step, from raw materials to final packing. Inspections include size checks with special machines, surface quality reviews, strength tests, and more.

These thorough checks lead to a product pass rate above 99%. This reduces the need for rework and ensures deliveries happen on time.

Following standards like GB/T 5237-2008 ensures parts are strong and resist rust. This makes them suitable for tough settings, like ships or factory automation systems.

Rich Experience Across Diverse Industries

Xihui Aluminium brings years of knowledge to every custom CNC machining project. With over 20 years in aluminum processing, the company has made parts for industries like transportation, renewable energy, electronics cases, and more.

Xihui Aluminium has handled tough projects with tight measurements and short deadlines. This shows its skill and dependability under pressure. This experience lets Xihui Aluminium adapt to different needs while keeping parts precise. The company makes everything from light frames to decorative pieces that need perfect surfaces.

Comprehensive Service Offerings for Custom CNC Machining

Xihui Aluminium provides a wide range of CNC machining techniques to meet customer needs efficiently:

Key services include:

- Turning: Great for making round parts like shafts or bushings.

- Milling: Good for flat surfaces or complex shapes.

- Drilling: Creates precise holes based on design plans.

- Tapping: Adds threaded holes directly into aluminum shapes without extra pieces.

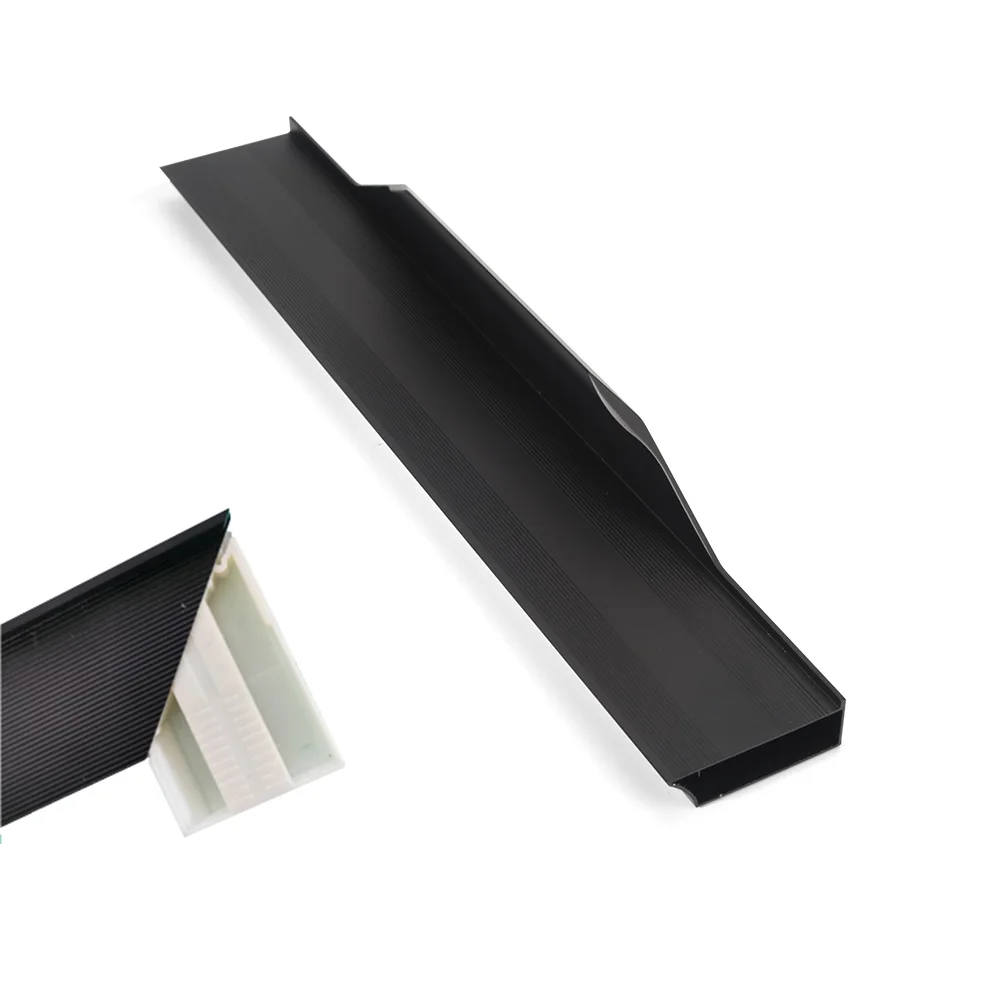

Beyond machining, Xihui Aluminium offers surface treatments like anodizing (in colors like natural, black, champagne, bronze, or gold), powder coating (any RAL color), sandblasting, and polishing.

These treatments make parts look better and last longer against wear or rust. This is key for outdoor uses or high-touch products like phones or kiosks.

Applications include:

- Aerospace parts, where light weight and strength are vital.

- Automotive frames that need to resist crashes.

- Electronics casings that require a sleek look.

- Factory automation systems needing strong connections.

Each solution is customized to fit the project’s goals, balancing function and appearance.

Highlights from Successful Collaborations

Xihui Aluminium has worked on many projects where custom shapes were made based on client details.

For example, the company sent special-shaped aluminum tubes to customers for medical equipment frames. These needed to be strong yet light. Another case involved decorative pieces for European car brands. These required perfect surfaces for visible areas in luxury vehicles.

Clients worldwide have praised Xihui Aluminium. They value the company’s quick responses, steady quality across orders, and ability to meet urgent deadlines without lowering standards.

End-to-End Customer Support System

From the first inquiry to after-delivery service, Xihui Aluminium offers full support focused on customer ease. The company provides fast quotes within 24 hours after receiving designs or details. Samples can be made quickly, letting clients test parts before starting full production. This lowers risk and speeds up project timelines. The engineering team helps during early planning. They suggest design tweaks to improve performance and cut costs. After-sales support includes warranties for manufacturing issues and ongoing help if assembly problems come up.

FAQs

Q1: What types of aluminum alloys can be used for custom CNC machining?

A: XiHui Aluminium works with many alloys. For example, 6063-T5/T6 is great for building projects because it shapes easily and resists rust. Alloys like 6061-T6 are stronger and suit structural parts. Clients can choose alloys based on their project’s needs during talks.

Q2: How long does it take from design submission to sample delivery?

A: Samples usually arrive within 7–15 days after designs are approved. Complex shapes or special surface treatments might take a bit longer. Still, Xihui Aluminium aims for quick delivery while keeping quality high.

Q3: Can you handle both small batch prototypes and large volume orders?

A: Yes. Xihui Aluminium supports orders of all sizes, from single test pieces to thousands of parts per month. The company’s flexible setup adjusts to meet project needs, making it ideal for startups or large manufacturers.