High-fidelity audio amplifiers need more than just amazing electronic design. They also require enclosures that show the same high level of precision and performance. When it comes to high-end audio gear, even a tiny flaw in the casing can hurt how customers see the product. It can also affect its long-term durability.

The surface finish on an amplifier’s aluminum casing is not just for looks. It’s also super important for managing heat, resisting corrosion, and shielding from electromagnetic interference. So, the quality of the CNC finishing really shapes both the visual appeal and the functional life of top-tier audio devices.

CNC Machining and Its Role in High-End Audio Enclosures

Precise manufacturing is key to delivering steady quality from one batch to the next. For this reason, CNC machining has become the top choice for making aluminum casings with tight tolerances and complex features.

Overview of CNC Machining for Aluminum Casings

First of all, what is CNC machining? It stands for Computer Numerical Control. This process involves automated tools that follow digital commands to cut, drill, and shape materials with amazing accuracy. For audio enclosures, this method is usually used on aluminum alloys like 6061, 6063, or 7075. These materials are chosen because they are easy to machine and have great thermal properties.

Advantages of CNC Machining in Audio Equipment Manufacturing

CNC machining surface finish techniques bring several benefits that are absolutely essential for high-end audio products.

Tolerances and Repeatability for Consistent Quality

A major plus is the ability to keep very tight tolerances across huge production runs. Our processes are ISO 9001-certified. Thus, they follow a ±0.01mm tolerance standard. This ensures every single enclosure fits perfectly with the parts inside, which cuts down on vibration and makes the sound clearer.

Design Flexibility for Custom Enclosure Features

CNC also lets manufacturers create advanced designs. For example, they can build heat sinks, mounting brackets, or acoustic chambers right into the casing itself. This gets rid of the need for extra parts and improves how well the product works.

Key Surface Finishing Techniques for CNC-Machined Aluminum Casings

After being machined, aluminum casings go through several finishing steps. These steps improve their look, sturdiness, and ability to resist corrosion. These CNC machining surface finish techniques are vital for getting a perfect final product.

Anodizing for Durability and Aesthetic Appeal

Anodizing is a very popular surface treatment for CNC-machined aluminum.

Benefits of Hard Anodized Finishes in Audio Applications

Hard anodizing forms a thick oxide layer on the surface. This layer greatly improves wear resistance. Besides, it also keeps its electrical insulation properties. This is perfect for protecting sensitive audio circuits from outside interference.

Color Options and Texture Control

We have stock colors available, like anodized silver-white and anodized black. These choices don’t just look good. They also let brands match the finish to their product’s identity. Anodizing also gives control over the texture, from a flat matte to a shiny gloss, depending on what’s needed.

Sandblasting, Polishing, and Brushing Techniques

These mechanical finishing methods are frequently used before or after anodizing to make the surface quality even better.

Achieving Uniform Matte or Glossy Surfaces

Sandblasting is a great first step. It gets rid of the tool marks left from machining and creates a smooth, matte texture that fits a modern industrial look. Polishing, on the other hand, creates a shiny, mirror-like surface often seen on luxury models.

Minimizing Surface Defects and Tool Marks

Brushing creates a pattern of straight lines. This look can hide small flaws and adds a nice tactile feel. It’s a perfect choice for the front panels or other visible parts of amplifiers.

Powder Coating and Other Protective Coatings

Powder coating offers a way to customize the look while also providing strong protection from the elements.

Enhancing Corrosion Resistance and Visual Impact

Powder coating, which comes in options like white and black, covers the surface completely. It offers custom colors and improves corrosion resistance. This is very important when devices are used in humid places or near heat sources, such as vacuum tubes.

Challenges in Achieving Flawless CNC Finishes for Audio Amplifiers

Even with today’s technology, getting a perfect finish means overcoming some technical difficulties during the manufacturing process.

Managing Material Properties During Machining and Finishing

Aluminum alloys are all a bit different. They vary in hardness and grain structure, which affects how they react to cutting tools or anodizing baths. It is very important to choose the right feed rates, tool angles, and pre-treatment steps to prevent warping or discoloration.

Preventing Surface Imperfections During Handling and Packaging

A part can be machined and finished perfectly, but improper handling can still cause scratches or dents. So, protective films have to be put on right after the finishing stages. This keeps the surfaces perfect during assembly and shipping.

Balancing Electrical Conductivity with Surface Treatment Requirements

Anodized layers are great insulators. However, some amplifier designs need grounding points where the raw aluminum has to be exposed. This means certain areas must be carefully masked during treatment. What’s more, this has to be done without messing up the finish on the surrounding areas.

Design Considerations for High-Fidelity Audio Casings

Designing an enclosure is about more than just looks. It has to support features that boost performance without making assembly too hard or adding too much weight.

Integrating Functionality with Form Through Machined Features

Custom machined profiles make it possible to build key features directly into the housing design.

Heat Dissipation and Ventilation Slots

Managing heat is crucial for tube amplifiers, which are known for getting quite hot. Precision-milled ventilation slots let air flow freely. This is done without weakening the structure or ruining the visual symmetry.

Mounting Points and Cable Routing Channels

Built-in mounting holes mean less need for glues or brackets. At the same time, cable channels keep the wiring neat. This helps reduce noise interference from tangled wires inside a small space.

Ensuring Assembly Efficiency Through Precision Engineering

High repeatability means every part lines up just right during the final assembly. This cuts down on labor time. It also ensures components are placed securely, which helps with long-term reliability as the device deals with vibration or temperature changes common in audio setups.

XiHui Aluminium: Expert Manufacturer of CNC-Machined Aluminum Profiles

When you need to combine technical skill with industry experience, XiHui Aluminium is a partner you can trust. We are relied upon by high-end electronics makers all over the world.

Company Profile and Capabilities

Our factory has been in business for 33 years, handling production and sales. Over that time, we’ve built a massive library of over 10,000 sets of molds for all kinds of designs. This deep experience means we can efficiently handle complex custom jobs for many industries, including electronics and renewable energy.

Over 33 Years of Experience in Aluminum Extrusion and CNC Machining

XiHui’s long history has led to proven methods. We can deliver precision parts at a large scale. It doesn’t matter if it’s a prototype for a unique amplifier housing or a massive order for global distribution.

ISO 9001-Certified Processes with ±0.01mm Tolerance Standards

This high level of accuracy ensures a perfect fit between parts. This is especially important for lining up front panels with internal circuit boards or connectors inside an amplifier.

Comprehensive Services from Prototyping to Final Finish

XiHui provides complete, end-to-end services. This approach shortens lead times and ensures quality control every step of the way:

- Materials Offered: 6061, 6063, 7075, ADC12, etc.

These material choices offer flexibility. You can pick based on the mechanical strength you need or the finishing preferences for different amplifier models.

- Surface Treatments: Anodizing, Powder Coating, Sandblasting

Custom sizes and colors are available. This allows you to fully match your brand identity goals with your technical performance needs through our custom CNC finishing solutions.

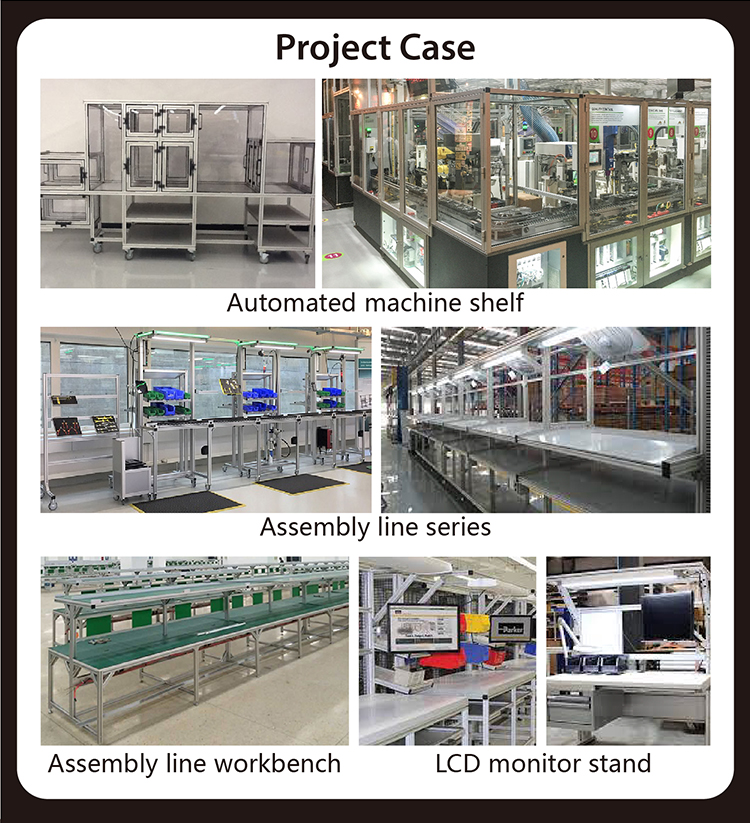

- Applications Across Automation, Electronics, Renewable Energy

Our experience across different industries means best practices are shared between projects. This helps drive innovation, including in the high-fidelity audio field.

Application Spotlight: Aluminum Casings for Linear Tube Audio Amplifiers

A great example comes from Tektonics. They are a boutique maker that specializes in handcrafted tube amplifiers. Their products are known for pure sound and a timeless design style.

How Tektonics Integrated CNC Machining into Their Design Workflow

Tektonics used XiHui’s prototyping services early on in their development. They were able to quickly test several enclosure ideas. In the end, they chose one that balanced great acoustics with a simple, clean look. They achieved this using brushed anodized finishes that were perfectly matched on every unit, thanks to the ±0.01mm tolerance standards from XiHui Aluminium’s ISO-certified production lines.

The Role of Finish Quality in Consumer Perception and Product Longevity

Customers see a perfect finish and think of craftsmanship. Any visible flaw can make a product seem less valuable in an instant. Tektonics saw fewer returns after their launch because the durable coatings resisted scratches during shipping. This success story shows the power of the solid CNC machining surface finish methods used by XiHui Aluminium’s teams.

Customized Solutions to Meet Assembly and Functional Demands

Everything was customized for Tektonics’ specific needs, from heat sinks milled right into the side walls to hidden cable paths under the base plates. And because of XiHui’s flexible mold library of over ten thousand sets, none of these features compromised the product’s beautiful design.

FAQs:

Q1: What makes CNC finishing ideal for high-end audio equipment?

A: CNC finishing offers incredible precision (+/- 0.01mm). This allows for a perfect fit between components. It also supports advanced surface treatments like anodizing, which improves both function (like corrosion resistance) and form (like brushed textures).

Q2: Can I customize both size and color when ordering aluminum casings?

A: Yes! You can fully customize both size and color. This includes options like oxidized silver-white or black finishes done through anodizing or powder coating methods. We tailor everything to your specific design needs.

Q3: How does XiHui Aluminium ensure consistent quality across orders?

A: We have over three decades of experience, ISO 9001 certification, and a ±0.01mm tolerance standard. Because of this, XiHui uses strict quality checks at every single stage—from extrusion all the way to final packaging—to deliver dependable results time after time.