In CNC machining, steady results are essential, not extra. From the initial test piece to the last batch of products, keeping sizes stable means every component works right in its setup. Even small changes can cause issues with strength, above all in vital areas like defense or medical tools. Our processes, certified under ISO 9001, create tough yet light parts with great protection against wear and solid heat flow. Such careful handling aids smooth checks, approvals, and large-scale making.

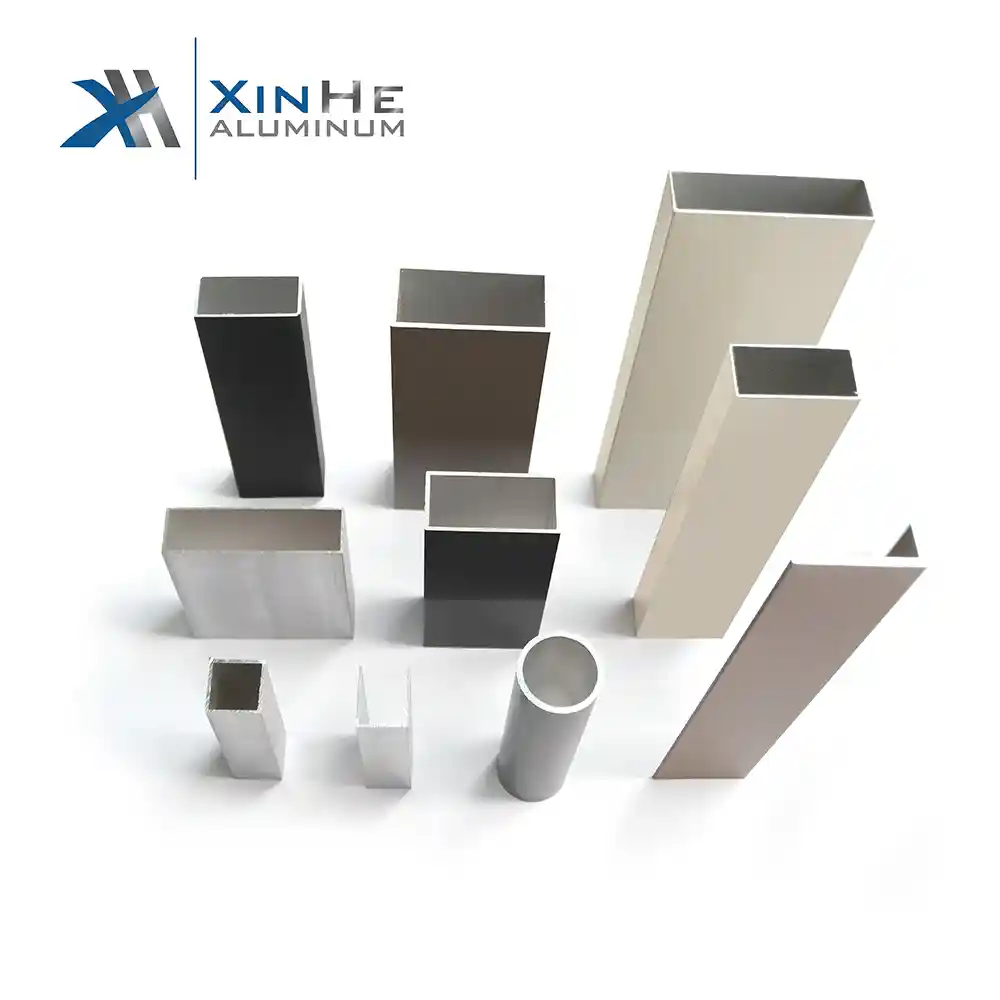

XiHui Aluminium: Turning Design into Reality with CNC Technology

Be it a small run of prototypes or a large order of products, XiHui Aluminium shines by changing digital plans into real items.Xihui Aluminium skills in managing tricky shapes and narrow limits positions them as a strong ally for designers who want fresh ideas without cutting corners. The company supplies precise, made-to-order CNC machined aluminum profiles built for key industry needs. They blend cutting-edge CNC machining with tolerances of ±0.01mm, high-quality alloys like 6061 and 7075, and full-range help—from quick prototypes to final surface treatments. As a result, CNC machining works well not just for early testing but also for growing production volumes with steady size control.

Highlighting the Company’s Custom CNC Machining Services

Customers can share 2D sketches or 3D files in formats like STEP, DWG, or DXF. Then, the technical staff provides test pieces or finished items ready to fit into systems. The offerings cover CNC Machining, CNC Milling and Turning, Laser Cutting, Drilling, Grinding, Bending, Stamping, Welding and so on.

Technical Strengths of XiHui Aluminium

XiHui Aluminium has a full set of exact tools. They use 3-axis, 4-axis, and 5-axis CNC setups that manage tolerances from ±0.005 to ±0.002mm. This arrangement supports fine details and work on multiple sides without resetting—perfect for items like cooling profiles or detailed casings.

How Does Their Engineering Team Drive Reliability?

With more than 40 machines, they meet 98% of shaping needs. The technical group has plenty of hands-on know-how in CAD/CAM setup and tool holding. This leads to better arrangements that cut down on mistakes during runs. Plus, their steps flow smoothly from digital files to machine instructions and check routines.

How Rigorous is XiHui’s Quality Assurance?

At XiHui, checks for quality happen at each stage. Tools like CMM, or Coordinate Measuring Machine, confirm that all pieces meet shape limits. And every delivery comes with a full check report to match ISO rules.

What Sets Their Experience Apart in Aluminum Machining?

After over 30 years in aluminum shaping and handling, they hold solid insights into how alloys act. Choices in materials cover A2017/A2024/A5052/A6061/A6063/A7075 T5/T6 types, picked for the best balance of power and lightness.

Comprehensive Customization Capabilities

Sure—they handle test runs starting from just one item and grow to big production lots. The usual lowest order is around 500KG per type, which fits even small-scale uses. When teams work together from the start of planning, XiHui’s experts use DFM ideas to trim extra steps while keeping the core purpose. In turn, this cuts expenses on tools and speeds up timelines.

Precision CNC Machining Processes at XiHui Aluminium

Turning (Lathe Processing): This method suits round, even parts such as rods and sleeves. Milling (Vertical/Horizontal/5-Axis Milling): It’s common for items needing curves, cuts, grooves, or flat designs.: Drilling and Tapping Operations. These steps guarantee exact openings and thread fits based on client details. EDM – Electrical Discharge Machining: They offer this as an extra option for spots that need special cuts or inner shapes beyond standard tools.

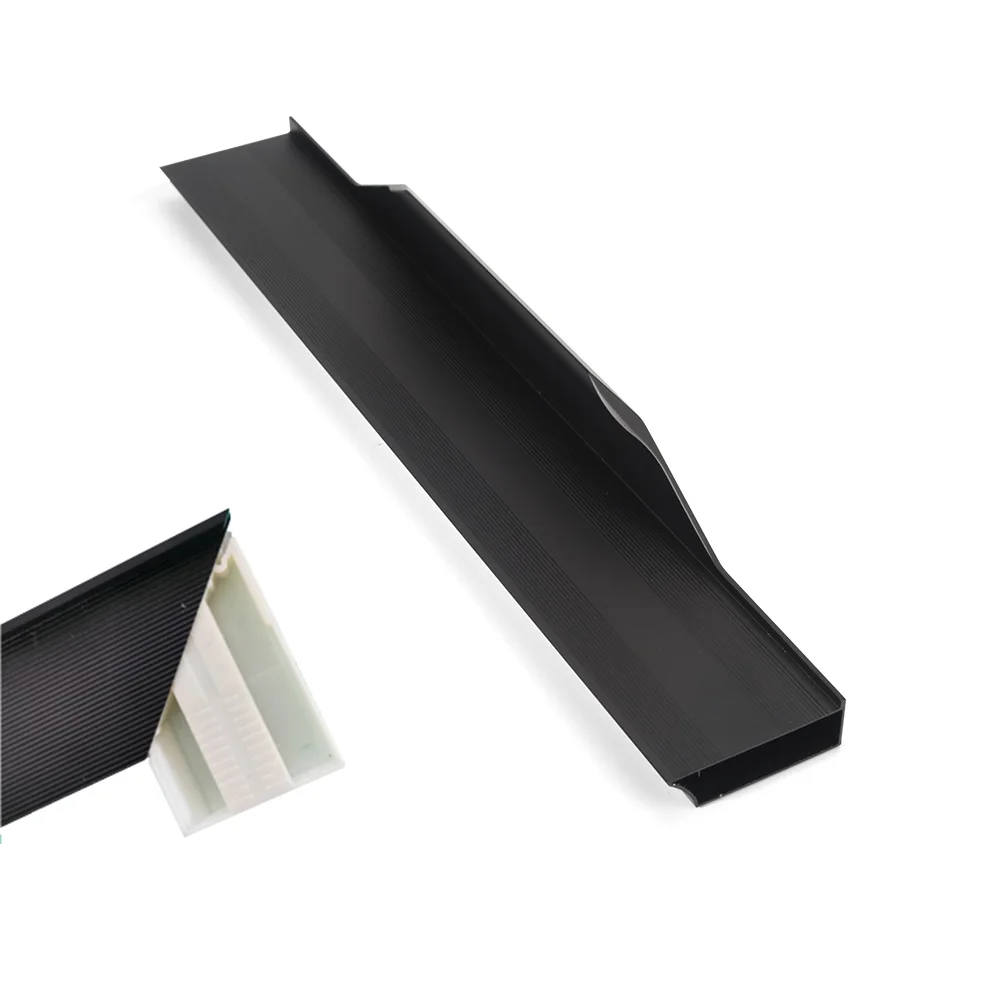

Surface Finishing Options Offered by XiHui Aluminium

Anodizing (Type II / III): Surface treatment includes anodized, powder coated, sand blasted, polishing, mill finish etc. Type III hard anodizing raises toughness against scratches and gives style choices with various colors. Sandblasting / Bead Blasting: It clears away marks from tools and creates an even, dull look that’s great before other coatings. Powder Coating / Painting: This brings color layers that resist sun fade, fitting well for items seen by users or marked for business use. Brushing / Polishing / Mirror Finishing: These apply where looks count most, like on covers or show pieces.

Application Sectors Served by Custom Aluminum CNC Machining

Aerospace & Defense: Parts for plane frames and electronics boxes gain from the low weight of alloys like 7075, with close limits. Automotive & Electric Vehicles: Shaped aluminum sections fit EV power pack covers and support frames that need strong heat transfer. Consumer Electronics & IoT Devices: Cut casings provide block against signals and clean shapes key for handheld gadgets. Medical Devices & Laboratory Equipment: CNC aluminum pieces bring safe contact with bodies and ease in cleaning, vital for health settings.

Customer Support Throughout the Project Lifecycle

Free drawing service, new product design support, and rapid mold production available within 7 days. Such perks speed up getting products to market a lot. In stock: Goods will be ready for shipment within 3-5 days after placing the order. Test items get focus through special lines for quick small jobs. Buyers get steady help after—from fixing size problems to backed fixes under warranty.

Why Choose XiHui Aluminium as Your Manufacturing Partner

One-stop Customization Service:Everything from base materials to last touches happens in one place. Short Lead Times & Global Shipping Capability: Quick sends in 7–15 days, backed by worldwide transport help. High Repeatability Across Batches: Firm controls keep results steady, even as orders grow bigger.

Key Takeaways Before Partnering with XiHui Aluminium

Exact CNC machining links early tests to full making at scale. XiHui Aluminium mixes solid skills, flexible tailoring, tight check steps—and that makes them a top choice for precise field needs.

FAQ

Q1.What is the minimum order quantity (MOQ) for custom aluminum CNC machining?

A1:Many jobs start with an MOQ of just 1 piece based on how tricky it is; better rates come for bigger amounts.

Q2.What surface treatment options are available for machined aluminum parts?

A2:Choices cover anodizing in clear or colors, sandblasting, powder coating, brushing or polishing, and painting to fit what the job needs.

Q3.Does the manufacturer support structured data markup (Schema) on product pages?

A3:Yes, product pages use structured data markup to boost search rankings with extras like prices or feedback snippets.