Precision work forms the backbone of today’s heavy-duty machines, where even the tiniest robot parts demand exact builds alongside massive belt systems that keep production humming. Aluminum mounting plates stand out here. They deliver firm support while ensuring everything stays lined up and steady under constant pressure.

These plates matter most in tough spots, like environments where heavy loads, scorching temperatures, or harsh chemicals constantly test the material’s toughness and force it to hold up without fail. New ways like fast CNC plasma cutting push the limits of what’s possible. Factories now hit top-notch sharpness and staying power that older methods could only dream of.

Fast CNC plasma cutting flips the script on making special aluminum bits by mixing quick work with sharp, reliable cuts that let makers shape each plate just right for the job at hand. That’s why it’s a must-have in the push toward smart factories, where every second and every inch counts.

CNC Plasma Cutting Technology Overview

CNC plasma cutting shapes metal with a computer-guided hot arc that slices through tricky forms from sheets both fast and even, making it a go-to choice for shops handling everything from basic jobs to intricate designs. Folks love it for tackling steels, stainless, and aluminum alike without breaking a sweat.

Advantages of High-Speed CNC Plasma Cutting Over Traditional Methods

Old-school cuts like saws or lasers can’t keep up with the pace and precision of modern demands in fabrication shops. Fast CNC plasma wins big here. It speeds through jobs while keeping waste low and edges smoother than ever before. What’s more, it chews through thick or thin stuff easily, proving ideal for light gear or beefy setups that need quick turnaround.

CNC brains make sure every cut sticks closely to the original plan, so errors fade away and no big hand tweaks are needed during the run. Thus, costs for workers shrink noticeably. Big batches repeat like clockwork, boosting overall efficiency in high-volume settings.

Key Components and Operation of a CNC Plasma Cutter

Most setups pack a power box, a torch tip, a brain controller, and a flat table to handle the workflow smoothly from start to finish. The power box sparks the zap for the arc that does the heavy lifting. Metal melts on touch.

The controller reads design files with precision. It steers the torch right along the marked paths without deviation. The table holds the sheet steady throughout the process. Advanced rigs add auto-height tricks for reliability. They keep the gap just so, even on bumpy stock that might otherwise throw things off.

Custom Plasma Cutting for Aluminum Mounting Plates

To get into real-world uses that highlight the tech’s strengths, grasp first why aluminum fits the bill so well for these demanding roles.

Why Aluminum is Preferred for Industrial Mounting Plates

Aluminum rules in factory builds because it packs serious punch per pound while fighting off rust with ease and machining up smoothly for quick adaptations. These perks shine brightest for frames needing grit and slim weight to perform under daily grind. Often, folks zap it with anodizing for extra protection. That boosts rust-proofing and wear hold in ways that keep parts lasting longer. Harsh shops thank it every day.

Tailoring Designs Through Custom Plasma Cutting Services

Bespoke plasma jobs let shops craft plates for odd machine fits that standard parts just can’t handle alone. CAD ties into CNC for seamless flow from drawing to done. Slots, holes, bends—all slice clean without a hitch. No hand fixes required. This level of tweak locks in top fit and zip across jobs, from bot bases that need agility to belt runners demanding endurance.

Achieving Strength and Precision with CNC Technology

Tight specs from quick CNC plasma nail fancy shapes dead-on, ensuring the final product meets every tolerance without compromise. Pair it with tough aluminum like 6061 or 6063 in T5 or T6 moods for unbeatable results. Parts gain killer pull and true sizes that stand up to scrutiny.

Fabrication Process of Aluminum Mounting Plates

From blank sheet to ready piece that bolts right into place, steps lock in top marks and zip through each phase efficiently.

Material Selection and Preparation for Cutting

Pick the alloy first based on weight needs and rough spots it might face down the line. Clean sheets thoroughly. Clamp them flat on the table. Ready for the zap.

Programming and Design Input in CNC Systems

Design folks sketch CAD shapes for the plate with an eye on efficiency and strength from the outset. Turn them to G-code commands that the machine follows without question. Tweak here to cut scrap and boost frame smarts too, so nothing goes to waste.

Execution of High-Speed Cuts for Complex Geometries

Hit go on the program. The cutter races along paths with speed and accuracy. Fancy voids, slants, or lock tabs emerge crisp and ready. Perfect for snap-together kits that save time on the floor.

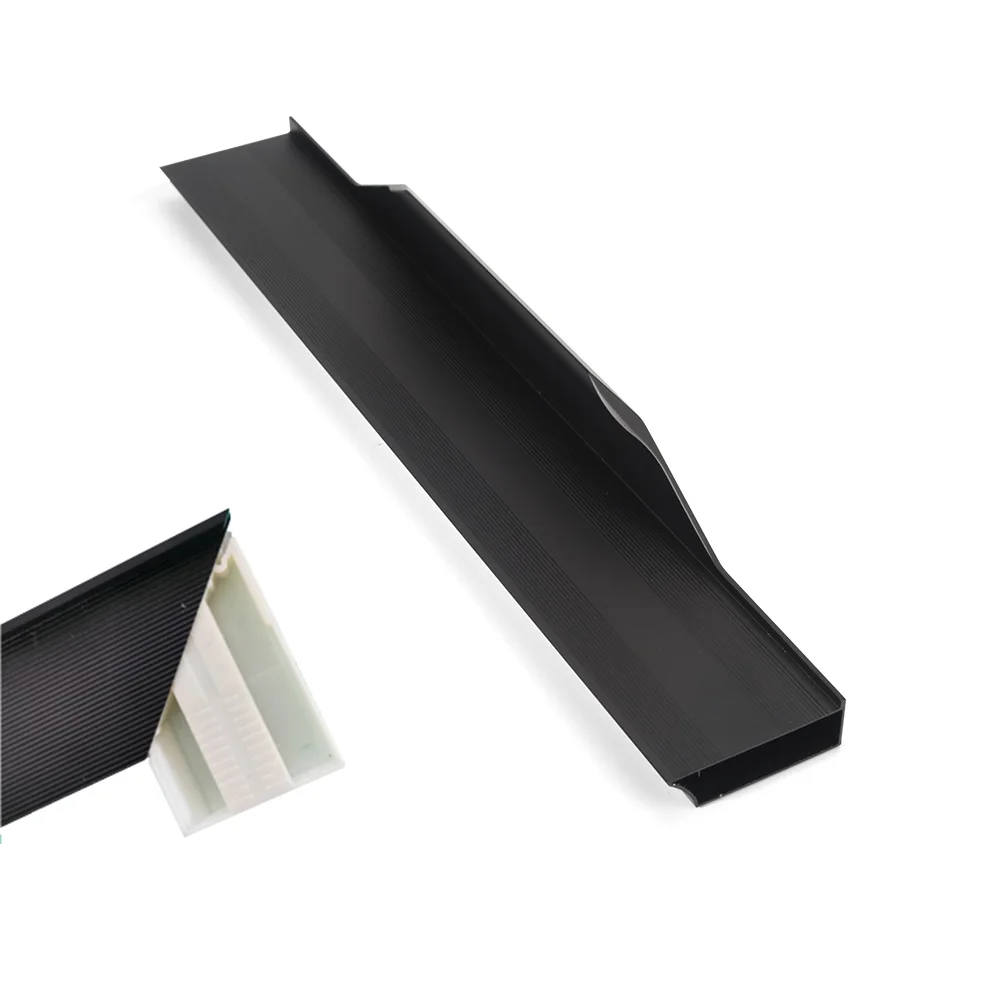

Post-Cutting Processes: Deburring, Surface Treatment, and Quality Inspection

Rough edges demand attention next to ensure safe handling. Deburr sharp bits carefully. Add anodize or powder for rust shield—or looks that match the setup. Choices run wild: bright colors, tough coats, even wood-look vibes for unique touches. Check last for peace of mind. Sizes spot-on. Faces clean. Ship it out.

Performance Benefits of CNC-Machined Aluminum Mounting Plates

Bespoke plasma on aluminum yields parts with killer upsides that pay off in factory gigs day after day.

Enhanced Durability and Load-Bearing Capacity

Alloys like 6061-T6 pull hard yet stay light enough to keep systems agile under full tilt. Precise cuts spread force fair across the surface. No warp under push that could spell trouble later.

Dimensional Accuracy for Seamless Machine Integration

CNC nails the measures down to fractions that make a real difference in tight builds. Every bit slots home without force. Assembly speeds up dramatically. This accuracy prevents misalignment issues that plague lesser parts. Downtime drops low.

Resistance to Corrosion and Environmental Degradation

Post-zap coats fend off wet spells, chemical bites, and wild swings in heat that wear down ordinary materials. Key for grub lines or yard works exposed to the elements year-round.

Applications in Industrial Machinery

These traits make plasma-cut aluminum plates a staple in setups where tough frames rule the roost and reliability isn’t optional.

Use Cases Across Manufacturing Sectors

Plates anchor key spots across the board in ways that streamline operations. Here’s where they shine brightest:

- Automation Equipment and Robotics Systems: Sharp-cut aluminum holds sensors, movers, and brains steady on bot limbs or self-steer carts that zip through warehouses.

- Heavy-Duty Assembly Lines: In car or gadget lines under constant pressure, they base clamps and tools firm to keep the pace relentless.

- Precision Instrumentation Platforms: Lab gear and measure rigs lean on steady pads for unerring results. Only CNC cuts deliver that true hold without flex.

Importance of Reliable Mounting Solutions in High-Stress Environments

Shake from vibrations, scorch from nearby heat, or sour air thick with fumes—it’s brutal out there in the thick of it. Solid mounts become non-stop need for survival. Plasma-cut aluminum hangs tough through it all. No quit when it counts.

XiHui Aluminium: Your Partner in Precision Aluminum Fabrication

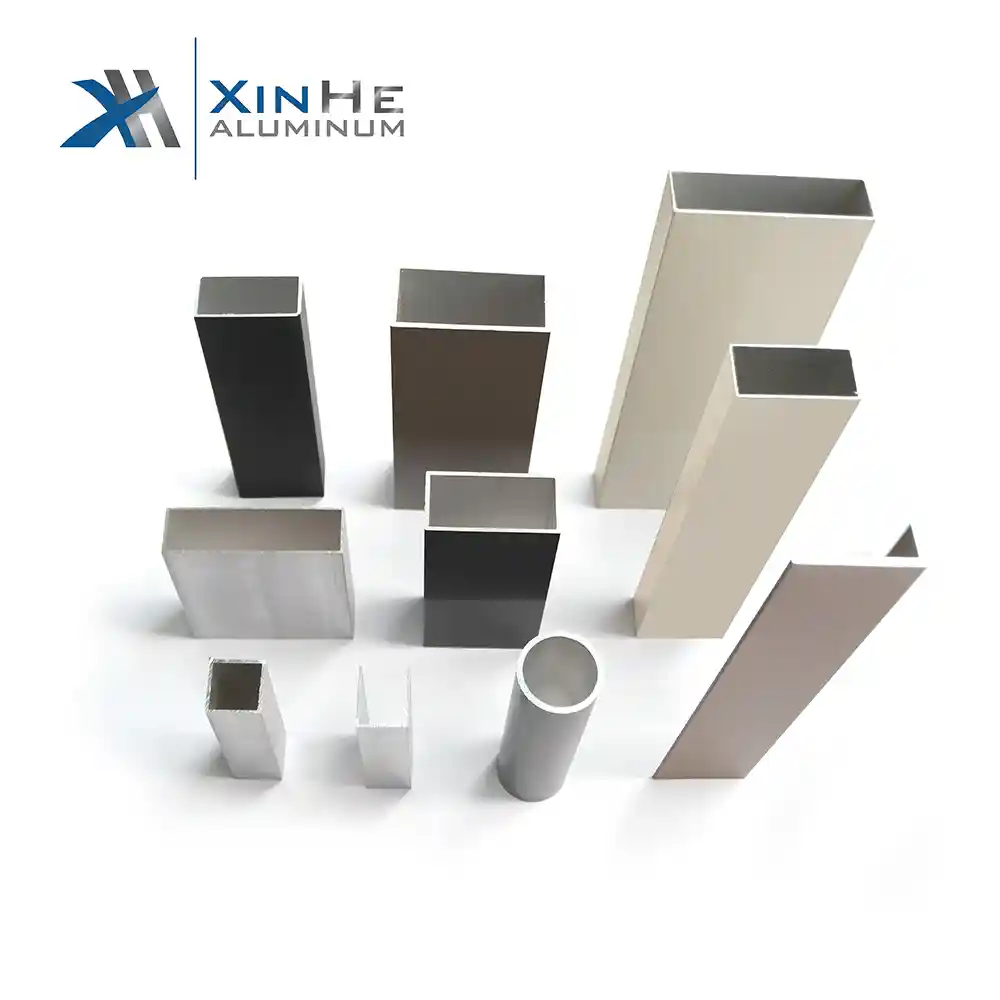

Top picks in this field include Foshan Xihui Aluminium Co., Ltd., where they crank out prime extrusion bars and cut jobs that meet the mark every time.

Company Background and Manufacturing Capabilities

Thirty-three years in the game have built a solid rep, with sales keeping pace through thick and thin. Stock runs deep—tens of thousands of molds ready for action. Endless styles to choose from. Custom molds? Just draw it up and they’ll build without delay. Shelf holds norms like 3030, 4040, 6060, 100100 bars. All factory-fit for seamless use.

Expertise in Custom CNC Machining and Profile Extrusion

Mold magic starts from your sketch and turns into reality fast. Finishes galore await: hue anodize for pop, powder blasts for toughness, wood grains for flair. Blend extrusion with sharp CNC for steady wins. Quality holds firm for stock or specials alike.

Commitment to Quality Control and Client Satisfaction

Happy clients drive them forward with feedback that shapes the next run. Pro engineers hand assembly pics clear as day. Install tips tailored to your ask make setup a breeze.

FAQs

Q1: What makes custom plasma cutting more suitable than laser cutting for aluminum plates?

A: Both nail sharp work in their own right, but plasma saves cash on fat sheets where thickness matters most. Speeds fly on zap-friendly stuff without skimping. Edges hold crisp through it all.

Q2: Can CNC plasma cutters handle high-volume production runs?

A: Sure, they thrive on it. Program once for wild shapes. Replicate steady over tons of runs with little drift. Scales sweet for factory floods that never sleep.

Q3: Are there limitations on the thickness of aluminum that can be cut using plasma technology?

A: Power sets the roof high—up to inches deep on beefier rigs. Best bets land in 1mm to 50mm sheets. Smooth sails there every time.