In today’s fast-changing world of making things, custom solutions are key to meeting special needs. At XiHui Aluminium, we focus on aluminum alloy customization. We use advanced CNC processing to make accurate profiles. These improve your projects. This blog looks at how custom CNC processing boosts aluminum alloy profiles. It covers the basics, benefits, uses, and key factors. It also shows our skill in delivering solutions just for you.

The Basics of CNC Processing for Aluminum Alloy Profiles

What is CNC Processing?

CNC processing uses machines controlled by computers. They shape materials through cutting, milling, turning, and drilling. For aluminum alloys, CNC machines follow digital plans. This creates profiles with exact sizes. It ensures steady quality for small or large batches.

Key Features of Aluminum Alloy Profiles in CNC Applications

Aluminum alloys are great for CNC processing. They have special traits:

- Light: Reduces weight in uses like airplanes and cars.

- Rust-Proof: Lasts long in tough conditions.

- Easy to Shape: Allows smooth, fast processing.

- Strong but Light: Keeps strength without being heavy.

These traits make aluminum alloy profiles useful for many fields.

Benefits of Using Aluminum Alloys in CNC Processing

Aluminum alloys bring many advantages to CNC work:

- Easy to Work With: Needs less cutting force, so work is faster.

- Reusable: Supports green manufacturing.

- Good Heat Flow: Great for parts that need to lose heat.

- Nice Look: Gets smooth, shiny surfaces with little extra work.

These benefits make CNC-processed profiles better and faster to make.

The Advantages of Customization in CNC Processing

Customization makes CNC processing special. It lets makers meet exact project needs with accuracy.

Tailored Solutions for Specific Requirements

Custom CNC processing creates aluminum alloy profiles made to exact needs. You might want unique shapes, sizes, or finishes. Customization ensures parts fit your project perfectly. This cuts waste and saves time during assembly.

Enhanced Precision and Quality Through Customization

Customization uses digital plans and advanced CNC machines. It achieves measurements as tight as ±0.001 inches. This accuracy creates top-quality profiles. They meet strict rules for fields like airplanes and medical tools.

Cost-Effectiveness and Material Optimization

Customization saves material by reducing waste. CNC machines follow exact tool paths. This cuts down on extra material removal. It lowers costs while keeping quality. Custom solutions are affordable for all kinds of businesses.

Applications of Customized CNC Aluminum Alloy Profiles

Custom aluminum alloy profiles help many fields. They deliver strong, reliable results.

Aerospace and Automotive Industries

In airplanes, light aluminum profiles save fuel. They still keep strength. Cars use them for chassis parts and engine pieces. Accuracy is very important here. Our custom industrial 5-axis CNC milling services offer solutions for these tough fields.

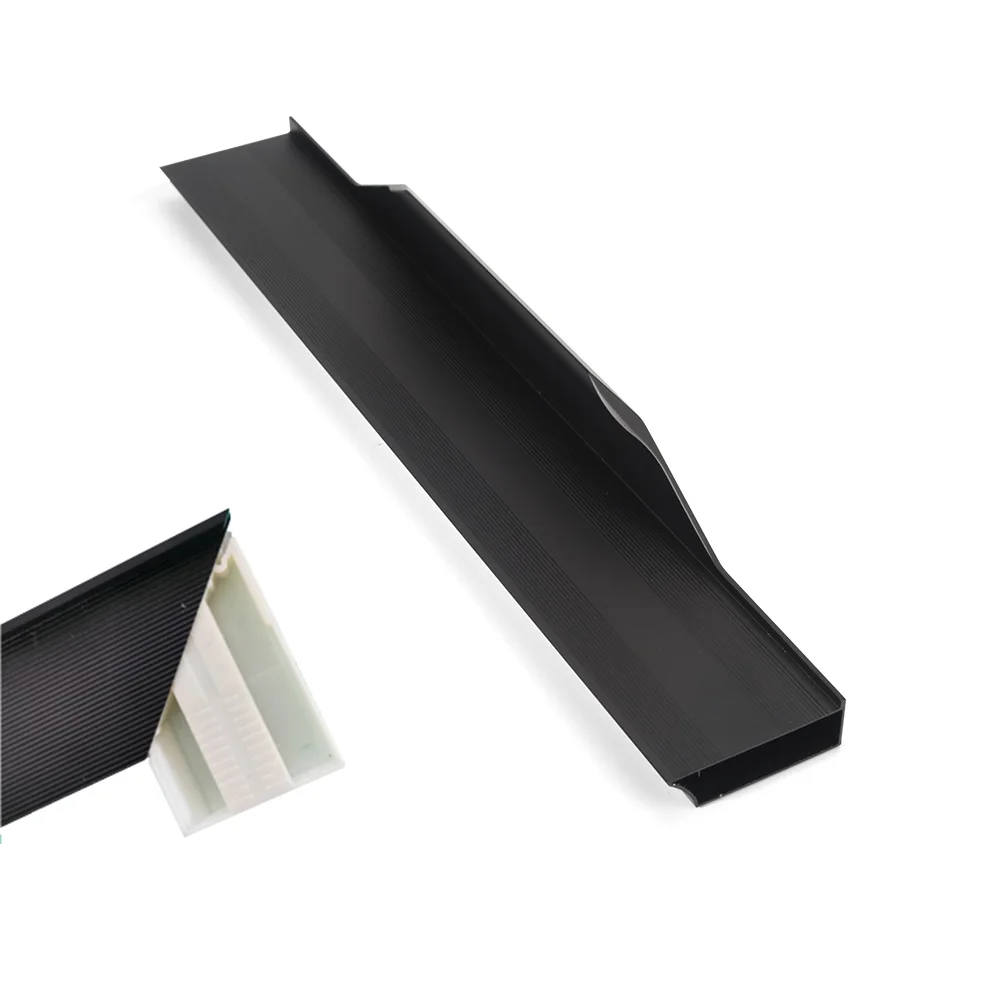

Architectural and Construction Applications

Aluminum alloy profiles are used in window frames, wall systems, and supports. They are strong and look good. Custom CNC processing makes profiles fit specific building designs. This improves both use and appearance.

Electronics and Consumer Goods Manufacturing

In electronics, aluminum profiles work as heat sinks and covers. They use their good heat flow. Everyday items, like phone frames, benefit from custom finishes. Our customized CNC-machined aluminum parts support these uses with accuracy.

Factors to Consider When Opting for Customized CNC Processing

Choosing custom CNC processing needs careful thought to ensure success.

Choosing the Right Aluminum Alloy Grade

Different aluminum alloy grades have different traits:

| Grade | Key Features | Uses |

| 6061 | Strong, rust-proof | Building parts |

| 7075 | Very strong | Airplane parts |

| 5052 | Easy to shape, weldable | Boats, building uses |

Picking the right grade matches your project’s needs.

Evaluating Design Complexity and Feasibility

Complex designs need advanced CNC tools, like 5-axis machining. This creates detailed shapes. Checking if designs can be made early avoids quality issues or extra costs.

Importance of Partnering with Experienced Suppliers

A skilled supplier, like XiHui Aluminium, knows materials, design, and quality control. Their experience ensures your custom profiles meet your goals. This saves time and money.

XiHui Aluminium: Your Reliable CNC Aluminum Profile Supplier

Overview of XiHui Aluminium’s Expertise

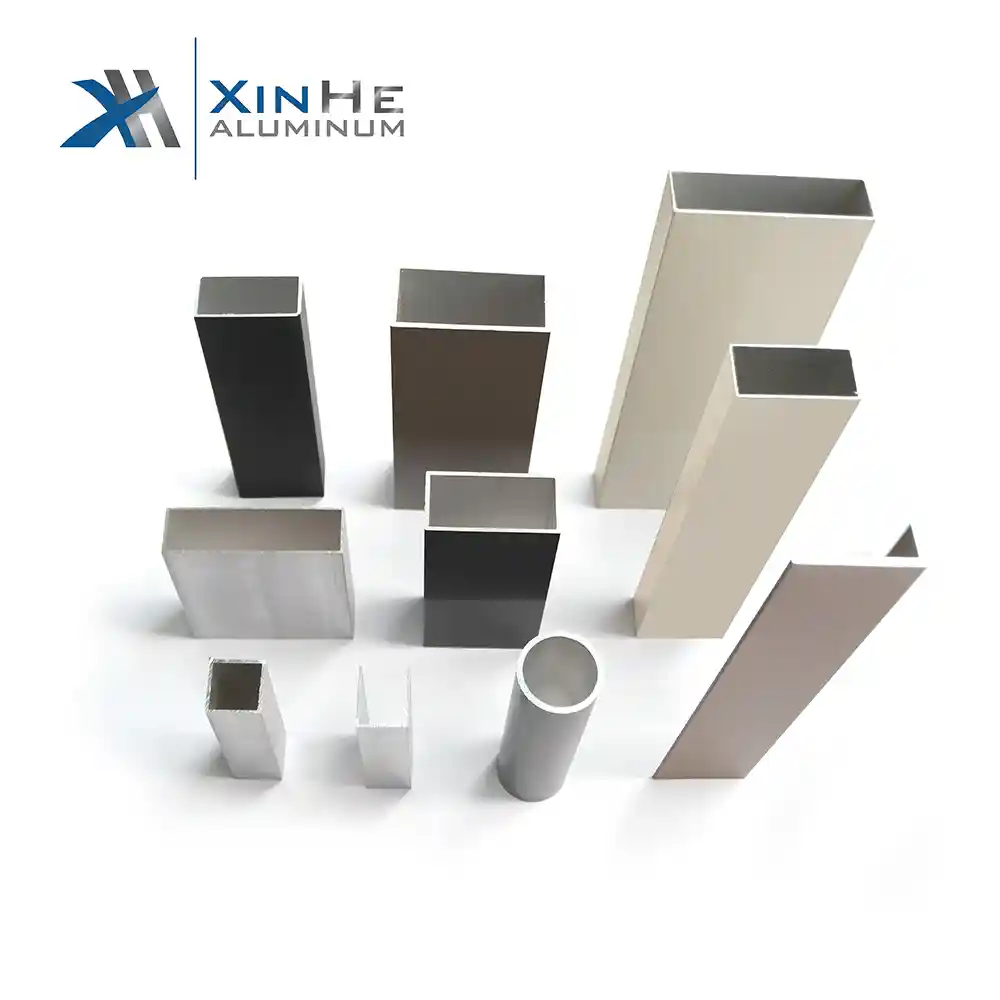

At XiHui Aluminium, we are great at accurate aluminum alloy profile processing. We use advanced CNC equipment. Our factory is in Foshan, China. It covers 10,000 square meters. We work from customers’ drawings or samples. This delivers custom profiles that match exact needs. Our skilled team handles small samples to big production runs. We offer flexible, personal service. Check out our high-quality CNC aluminum machined parts for your next project.

Why Choose XiHui Aluminium for Customized Solutions

We stand out for our focus on excellence:

- Modern CNC Tools: Our 5-axis machines achieve tiny measurements.

- Flexible Customization: We make profiles to fit your unique plans or samples.

- Worldwide Service: We deliver to clients everywhere on time.

Commitment to Quality and Customer Satisfaction

We focus on quality with strict testing. We follow global standards. Our customer-first approach ensures custom solutions that go beyond what you expect. This makes us a trusted partner for your aluminum alloy needs.

Conclusion

Recap of the Benefits of Customized CNC Processing

Custom CNC processing improves aluminum alloy profiles with solutions made for you. It offers great accuracy and saves money by using materials wisely. It works for many fields, from airplanes to electronics, with top quality.

Final Thoughts on Enhancing Aluminum Alloy Profiles

As making things changes, custom CNC processing will keep driving new ideas. By using advanced tools and expert suppliers, businesses can make the most of aluminum alloy profiles. Ready to improve your projects? Contact us to see how we can help.

FAQs

What are the key benefits of customized CNC processing for aluminum alloys?

Custom CNC processing offers designs made for you. It achieves high accuracy, up to ±0.001 inches. It saves costs by using materials well. It works for fields like airplanes and electronics.

How do I choose the right aluminum alloy grade for my project?

Think about your project’s needs. Use 6061 for strong building parts. Choose 7075 for high-stress uses. Pick 5052 for easy shaping. Talk to a skilled supplier to find the best grade.

Why is XiHui Aluminium a reliable choice for CNC aluminum profiles?

XiHui Aluminium offers modern CNC tools and flexible customization. We use drawings or samples. Our 10,000-square-meter factory and skilled team ensure top-quality parts and on-time delivery.