Custom CNC aluminum extrusion leads the way in today’s manufacturing world. It allows for exact changes from designs into practical and well-built parts. They cut down weight but keep the needed strength. These fields need parts with close limits and tricky forms. Advanced CNC machining methods, used after extrusion, make this possible. Our extruded aluminum heat sinks are built for top heat handling. They suit high-power LED lighting and other tough uses.

Modern computer numerical control (CNC) tech brings steady results, quick work, and fine surface looks. The mix of extrusion and CNC helps makers meet growing needs for smaller sizes, personal touches, and smart builds. This blend boosts overall efficiency in production lines.

XiHui Aluminium: Precision in Every Profile

Xihui Aluminium has over 40 sets of CNC tools. They cover 98% of machining needs. These tools include fast multi-axis centers that manage detailed shapes and curved surfaces. CAD/CAM systems work through the whole process. They make sure designs turn into real products without errors. Automation reaches more than 80%. So, steady work and high output stay reliable. This setup matters a lot for fields that want both quick test models and large-scale runs. It gives flexibility and scales up smoothly when needed.

How Are Customization Services Delivered?

Experts give advice on design tweaks for extrusion fit. Free drawing help and new item design aid make the shift from idea to mold simple. A special perk is the shared mold cost plan. Up to 100% of mold fees can be split based on order size promises. This eases costs for partners.

How is Quality Controlled from Start to Finish?

CNC Skimming (Ra≤0.8μm), Hard Anodizing (25μm), ±0.1mm Tolerance CMM measurements make sure every piece hits strict rules. ISO-certified systems watch over all steps—from extrusion to final machining. They keep things even for hard parts. Tests for heat flow, size checks, and material strength are routine in making. These steps build trust in the end results. Quality stays high across the board.

What Industry Expertise Has Been Accumulated?

Since 1993, this site has over 31 years in aluminum extrusion making. It has supplied key parts to clients in aerospace, electronics, energy, and mobility areas. The focus lies on aluminum extruded profiles. They excel at ultra-thin materials production. The on-site group knows global rules and material norms well. Things like 6061 and 6063 series alloys matter for worldwide sales. This know-how helps blend into markets easily.

What Innovations in Extrusion Techniques Drive Engineering Precision?

High-tolerance extrusion lets makers form detailed sections with little extra work after. It can create profiles up to 800mm wide in big sizes. These include paths, hollow spots, and fix points right in the shape. This cuts time on later machining and holds the build solid. Such skills shine in aerospace brackets or EV battery trays. There, saving weight and keeping accuracy top the list. It meets those demands head-on.

How Does Extrusion Geometry Optimize CNC Integration?

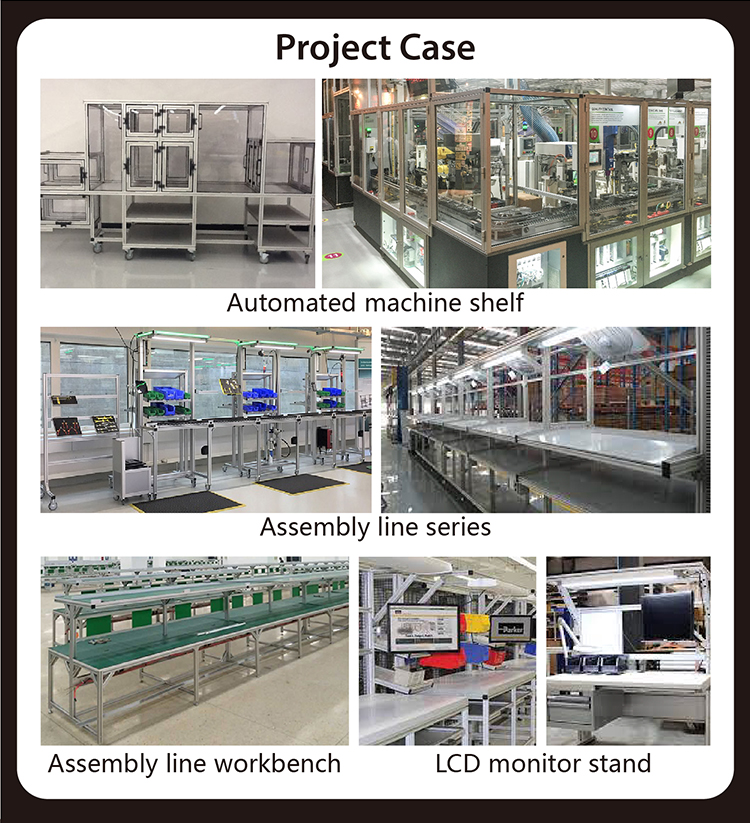

Setting key shapes in extrusion—like guide tabs or heat fins—lowers the call for tough CNC tasks. This shortens work cycles and uses material better. For example, aluminum T-slot profiles with even square parts fit well for build-your-own setups. Think industrial frames or automation setups. These designs make the whole process smoother. They tie extrusion and machining together neatly.

What Post-Extrusion Fabrication Is Enabled by Multi-Axis CNC?

Steps like turning, drilling, boring, tapping, and 5-axis milling reach tiny size limits on spots like seal areas or bolt joins. Xihui’s work includes uneven parts that need exact edge work. This makes them fit with nearby pieces. The range helps custom aluminum heat sinks with pin-fin setups or electronics boxes with built-in wire paths. It opens doors to varied uses.

Can Hybrid Methods Enhance Product Development?

Mixing extrusion with add-on making—like selective laser sintering—speeds up test builds of hard shapes. These would cost too much with old ways alone. It proves useful for research groups testing new ideas over and over before big tool setups. This approach speeds innovation.

Which Surface Finishing Techniques Improve Functionality and Appearance?

Aluminum pieces gain from many surface boosts. Anodizing boosts rust protection and gives color choices. Powder coating adds toughness and nice looks. Sandblasting makes a smooth dull feel. Brushing highlights straight line patterns. These not only look good but work better too. For heat sinks, they aid heat release. In electronics boxes, they stop electrical flow where needed. Overall, they lift both style and use. Explore more about aluminum extrusion heat sinks custom solutions tailored for LED thermal management applications.

Where Are These Technologies Being Applied?

Plane builds use light but tough parts like brackets and frames. These face heavy push without extra weight. Approved aluminum types like 6061-T6 meet plane rules. This keeps safety and performance in check.

Such materials handle the stresses of flight well. They support the whole structure reliably.

Why Is Aluminum Crucial in Automotive Structures?

Shaped profiles go into EV battery boxes. Aluminum’s strong heat pass helps cool things down. Frame parts gain from the light-to-strong balance. This boosts car range and safety levels. In modern vehicles, these traits drive better designs. They fit the push for green tech.

What Solutions Are Provided to Electronics Manufacturers?

Small electronics face heat issues in tight spots. These custom aluminum heat sinks give great heat spread, light build, and lasting strength. Fins get machined for best air flow based on the device’s setup. Consider aluminum alloy heat sinks as a tailored solution for electronics packaging needs. They solve common challenges effectively.

What Does a Typical Project Workflow Look Like?

Customers share CAD files or samples first. Then, engineers check if it’s buildable. Next, they pick the material grade, often 6061 or 6063. A test piece comes in 7–15 days. Changes follow if needed. Finally, full making starts. This clear path cuts time to market. It holds quality and strength steady all along. Teams work closely to avoid hiccups. Minimum order quantity begins at 500kg per type. Yet, it bends for research lots or special uses. This setup sparks new ideas. It avoids big stock loads on buyers. Flexibility keeps things open for all sizes.

How Is Customer Support Ensured Throughout the Process?

In-house skills trim wait times. Stock profiles ship in 3–5 days. Custom jobs need about 25–30 days, plus mold prep. Quotes come with build advice to check if it’s doable right away.This quick flow builds trust. Partners get clear paths from start to end. A set team handles warranty help, spare part finds, and tech talks—even after setup. It ensures parts last long in use. Support doesn’t stop at shipping. It carries on for ongoing needs.

Why Choose XiHui Aluminium as Your Manufacturing Partner?

If you want a quick partner to turn ideas into solid aluminum fixes with close sizes and great finishes, XiHui Aluminium brings top value. They do this through. Free drawing services. Rapid mold development. Shared mold costs. 98% process coverage via automation. Experience across aerospace to consumer goods. RoHS/REACH-certified materials. Their mix of fresh ideas and exact work means your product doesn’t just function—it stands out in its setting.

Key Insights on Advanced Aluminum Extrusion Techniques

Modern extrusion makes cheap builds of parts with wild shapes. Pair it with CNC work, and you get fresh levels of personal fit and sharp details. Smart teams like XiHui Aluminium give full support from idea to ship. They handle varied amounts and quick replies, making the whole journey smooth and effective. These methods push boundaries in design. They help create items that meet real-world tests with ease.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC-machined aluminum parts?

A1: The MOQ varies depending on the complexity of the part but typically starts from as low as 10 pieces to support prototyping needs.

Q2: What surface treatment options are available for CNC-machined aluminum?

A2: Available finishes include anodizing (clear or colored), powder coating, sandblasting, brushing, polishing, electrophoresis coating, and more based on application requirements.

Q3: Does XiHui Aluminium support structured data markup for product listings?

A3: Yes, structured data can be provided upon request to enhance SEO performance through rich media snippets such as product specifications and reviews on supported platforms.