In today’s fast-changing industrial world, the need for exact framing fixes has grown huge. Factories everywhere now see how key these strong setups are for smooth work and safe spots. Tech pushes forward. Standards get tougher. That’s why demand keeps climbing.

Why Customization Matters in Machine Frames and Guarding Systems

Tailoring fits right into machine frames and guard setups because it lets companies shape fixes to their own daily jobs. Custom builds give room to bend. They handle odd space limits and special tasks with ease. Thus, these systems slide into old workflows without a hitch. Productivity jumps. Safety holds firm.

Customization isn’t just nice. It’s vital. Businesses tweak frames to match exact needs, so operations run smoother and risks drop low.

The Role of Advanced Manufacturing Technologies in Modern Industry

Smart making tools shake up today’s factories by sparking spot-on and quick build steps. Methods like CNC machining and laser cutting sit at the heart of crafting parts with super-tight fits. They lock in match-ups and solid builds that last. What’s more, these tools craft tricky shapes that old ways couldn’t touch. Innovation spreads wide across fields.

Tech like this changes everything. It boosts output. And it cuts errors down fast.

T-Slot Machine Frames: Features and Benefits

T-Slot frames form the backbone of fresh factory builds for good reasons—they mix tough power, bendy options, and simple handling in ways nothing else does. Strength holds up under pressure. Flexibility lets you shift gears quick. Ease makes setup a breeze.

These frames shine bright. They solve real pains in engineering and shipping alike.

What Makes T-Slot Aluminum Frames Ideal for Industrial Use

Folks hail T-Slot aluminum frames as top picks for factory jobs thanks to core traits that tackle everyday build and move headaches head-on. Modularity rules here. You snap them together fast. Then tweak on the fly for new designs or shifts, skipping big overhauls. Dynamic shops love this. Adaptability rules the day.

Lightweight yet sturdy builds fit most spots without skimping on grit or staying power. Handling gets simple. Shipping stays cheap. Toughness weathers hard hits over time.

Assembly flows easy with these frames. Time drops. Labor bills shrink. Swap parts quick or fine-tune as needed. Shops optimize setups without sweat.

Applications of T-Slot Framing Systems Across Industries

T-Slot setups stretch far thanks to their all-around bend. They pop up in tons of fields and roles, from heavy lifts to fine tweaks.

Automation Equipment

In auto gear, T-Slot frames prop up wild machines while keeping doors wide for fix-ups. Structure stays rock-solid. Access flows free.

Safety Guarding and Enclosures

Guard walls gain big from T-Slot builds—they craft bendy shields that block dangers yet let eyes roam clear. Protection locks in. Views stay open.

Workstations and Material Handling Systems

Work benches from T-Slot stock deliver body-smart fixes tuned to job quirks, lifting ease and output for crews. Handling rigs use them too for slick hauls and stacks. Comfort rises. Flow speeds up.

Laser Cutting and CNC Milling in Frame Fabrication

img.

Two big guns in top-notch frame work are CNC machining and laser cutting; side by side, they nail exactness and top build quality every time. Precision drives the bus. Quality follows close.

These steps ensure parts mesh perfect. They stand tall against daily grind.

The Importance of Precision CNC Machining in Frame Components

Spot-on CNC work stands key in frame builds since it hits the narrow gaps needed for solid holds and flawless joins. Parts click together without fight, keeping the whole rig tough against work strains. Reliability shines through.

Exact sizes from CNC boost match-ups sharp, dodging build snags and lifting full system snap. Issues fade. Function climbs high.

First off, tight fits matter most. Then, strength follows suit.

Advantages of Laser Cutting for Custom Aluminum Parts

When shaping one-off aluminum bits, laser cutting brings clear wins that amp up build sharpness and speed alike. Clean cuts roll out with few rough spots. Runs fly fast. Efficiency soars.

Laser’s sharp eye squeezes max from stock by slashing scraps, trimming raw costs on the spot. Waste drops low. Savings stack up.

Besides, speed pairs with smarts. That’s the real edge.

Custom Aluminum Extrusions: Tailored to Your Requirements

Past off-the-shelf frames, one-off extrusions hand you wild freedom in shapes and spot-fit power that hits just right.

Custom work levels up the game. It fits like a glove for any pull.

How Custom Aluminum Profiles Improve Design Efficiency

One-off aluminum shapes boost plan smarts by handing over tuned fixes primed for their main gig. Profiles blend smooth into basic T-Slot lines, opening fresh build paths while holding tight ties. Possibilities explode. Links stay strong.

Shapes get tuned for load quirks, locking in build snap that nails must-haves spot-on. Performance peaks exact.

What’s more, tweaks save time. Designs flow freer.

Surface Treatments and Finishing Options for Extruded Profiles

Plenty of coat tricks wait to amp looks and work punch on end builds. Choices fit wide.

Anodizing fights rust hard. It adds shine picks in hues that suit job vibes. Appeal grabs eyes. Guard holds long.

Combining CNC Milling with Laser Cutting for Superior Results

To crank max speed and shine, these two heavy hitters team up in mixed plays that blend bests from each.

Hybrid ways pull from CNC’s sharp bite and laser’s quick dash. Output tunes prime. Steps slim down.

Streamlining Production Through Hybrid Manufacturing Techniques

Mixed builds grab CNC’s fine grind with laser’s zip to fine-tune make flows that cut drag and lift yields. Efficiency rules the floor. Waste takes a back seat.

Processes link tight. Gains roll in fast.

Improving Component Fit, Strength, and Visual Appeal

Blending these tricks yields bits with dead-on slots, beefed-up grit, and eye-pop polish that turns heads. Fit locks perfect. Power surges. Looks draw crowds.

Upgrades hit all marks. Builds feel alive.

Key Considerations When Choosing a Manufacturer for T-Slot Frames & Guarding Solutions

Picking the right maker means weighing core picks to land gear that clears your bar every time. Choices shape wins. Misses cost dear.

Look close. Dig deep.

Quality Control Standards in Precision Manufacturing

Makers must stick hard to check rules, locking steady shine that clears field bars without slip. Reliability stands firm. Specs hold true.

Checks run constant. Trust builds slow but sure.

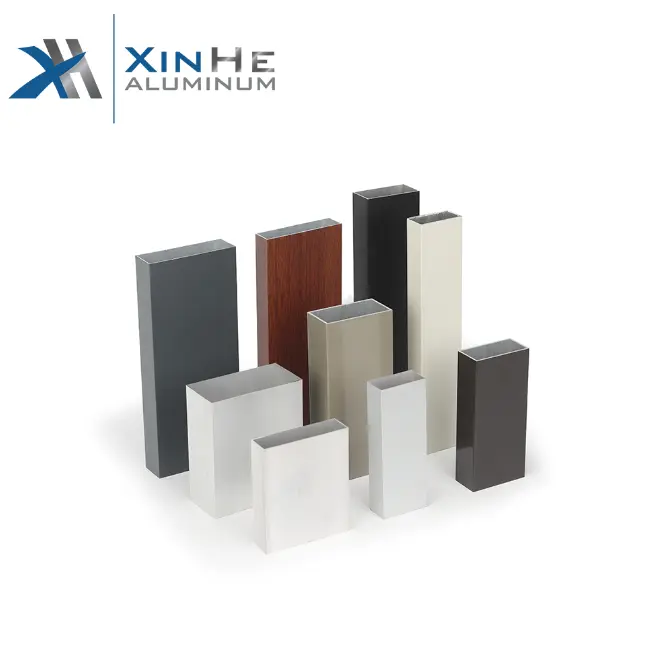

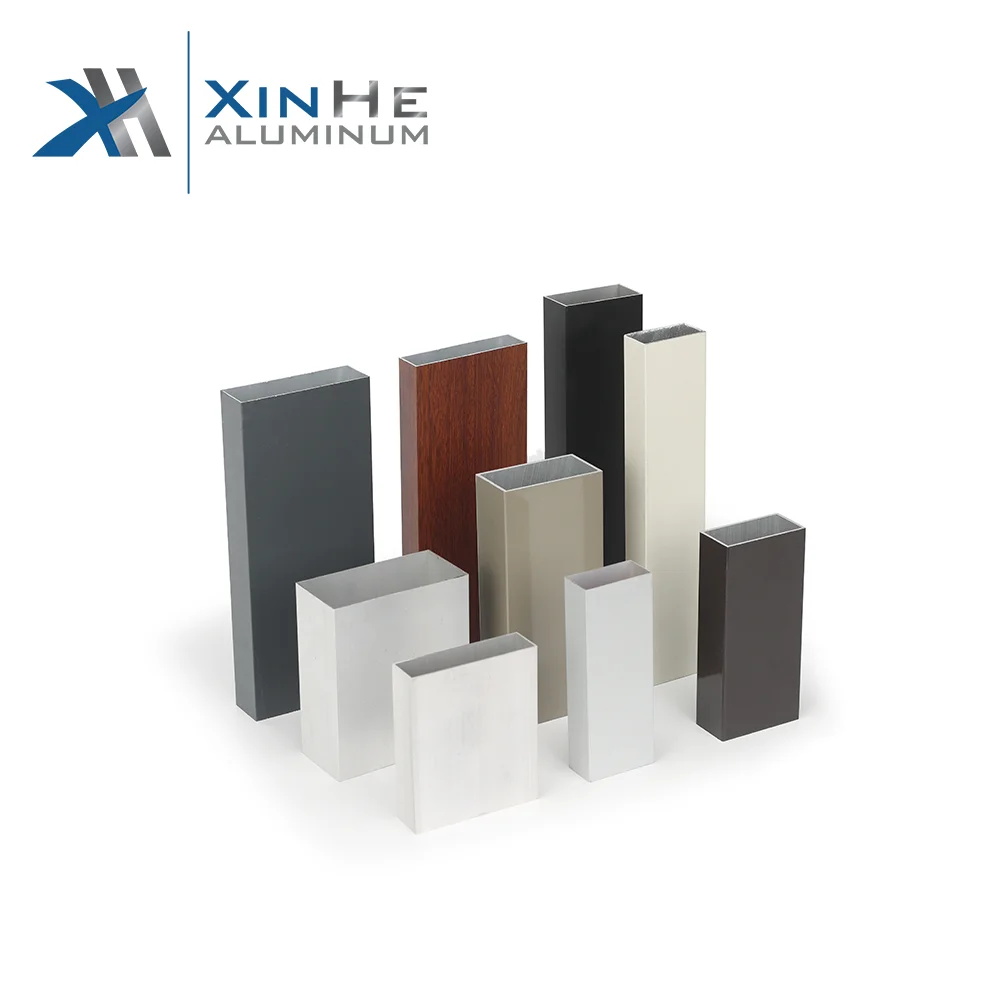

Material Selection: 6061 vs. 6063 Aluminum Alloys

img.

Spotting gaps in go-to mixes like 6061 against 6063 guides picks by job pulls, like grit wants over cut ease. We handle broad stocks, from hot picks like 3030, 4040, 4545, 5050, 6060, 6061, and 6063 lines, to cover build and role spreads wide. Strength calls one way. Machinability pulls another.

Alloys flex fit. Needs guide hands.

Lead Times, Scalability & Customization Capabilities

Sizing up a maker’s wait spans, grow room, and tweak power counts big for on-time drops that keep projects rolling. We boast quick flips, with shelf stock out the door in 3-5 days flat. One-off full loads clock 25-30 days. Smaller hauls slot per shop pulse now.

Times vary smart. Scale bends wide. Customs shine true.

Delivery waits test patience. But we ease the sting.

Introducing XiHui Aluminium: Your Trusted Partner in Aluminum Profile Manufacturing

XiHui Aluminium (Foshan XiHui Aluminium Co., Ltd.) steps up as your go-to buddy for full-frame and shape services that cover all bases.

We deliver deep. You get more.

Overview of XiHui’s Capabilities in CNC Machining & Extrusion Services

XiHui rolls out wide skills in sharp CNC work plus shape pulls tuned to client quirks across the board. Our crew packs build pros who dish full plan sketches and craft whole setup fixes from your wants. Needs met spot-on. Solutions flow custom.

Depth runs long. Trust follows quick.

Product Range: From Standard Profiles To Fully Customized Parts

Our lineup swings from quick-grab basic shapes in stock for fast ships to pure one-offs sketched to your blueprint. Standards sit ready. Customs build fresh.

Range hits every note. Picks stay open.

Commitment To Quality, Innovation & Customer Satisfaction

XiHui drives hard on prime gear fueled by fresh sparks aimed square at top client grins. Backed by 33 years in make and sell runs, our plant holds thousands of shape stamps, handing wild style spreads for any pull. Quality locks core. Sparks light paths. Smiles seal deals.

Years stack proof. Molds fuel variety.

FAQs

Q1: What are the main benefits of using custom aluminum extrusions?

A: Custom aluminum extrusions pack wins like sharper plan flows via tuned shapes, load-smart geometry that nails pulls, and smooth blends into basic setups. They toss in look boosts through coats like anodizing for rust blocks too. Efficiency climbs. Designs breathe free.

Q2: How do laser cutting techniques contribute towards efficient material utilization?

A: Laser cutting steps add big to stock smarts by rolling clean lines and slashing scraps sharp. Yields max out from base bits. Costs trim on runs. Waste shrinks small. Savings bite deep.

Q3: Why is precision CNC machining crucial within frame component fabrication?

A: Spot-on CNC work rules frame bit builds thanks to nailing narrow slots for hold snap, part match-ups that click, snag drops in joins, and full rig lift overall. Integrity stands tall. Function hums smooth. Issues bow out quick.