The need for energy-saving lighting solutions is growing very quickly in Russia. This is a big deal. The strong push for sustainability and environmental responsibility is a major reason for this incredible growth. As a result, LED lighting has begun to replace older lighting types in homes and industrial settings, which has created a sharp rise in the demand for high-performance LED fixtures. However, one of the main difficulties that manufacturers have in LED lighting design is handling the heat made by the LEDs. First of all, good heat dissipation is absolutely essential for the long life, dependability, and performance of these fixtures, and that’s where aluminum heat sinks play their part.

In this blog, we will look at two very important trends shaping the LED aluminum heat sink market in Russia—miniaturization and integration. These trends are creating a need for new aluminum extrusion solutions that not only handle the thermal management needs of modern LED lighting but also serve the changing requirements of manufacturers in Russia.

The Market Context for LED Lighting in Russia

The LED lighting market in Russia has been getting bigger and bigger as energy efficiency becomes a top priority for both businesses and industries. Government programs that encourage energy-saving lighting solutions are also speeding this trend up. For instance, a lot of cities are switching from old-fashioned lighting to energy-saving LED lights. This is for street lamps. It is also for floodlights and industrial lighting. As energy costs go up and environmental worries increase, the change to LED lighting provides both money-saving and ecological advantages.

In this situation, thermal management becomes a huge challenge. LEDs are well-known for how little energy they use. But they also create a lot of heat. Without a good way to get rid of that heat, the LEDs can wear out faster, and this reduces their performance and how long they last. This is why aluminum heat sinks—which do a great job of pulling heat away from the LED modules—become such vital parts for keeping the lights reliable and efficient.

What’s more, the tough climate in Russia adds another level of difficulty, with its cold temperatures, high humidity, and severe freeze-thaw cycles. LED heat sinks used for outdoor lighting must be able to handle these conditions. This makes choosing the right material and design even more critical.

Key Trends: Miniaturization of LED Aluminum Heat Sinks

As LED technology keeps getting better, there is a major push for more compact, high-power LED modules. They are small. These smaller, more powerful modules frequently need heat sinks that can work well in a tighter space. Thus, the trend toward miniaturization is one of the most important developments in the LED aluminum heat sink market.

With more and more high-power LED modules being used, manufacturers are now facing the difficulty of dissipating heat from these ever-smaller fixtures. Old-fashioned large heat sinks might not work for these smaller modules. So, creative designs are necessary.

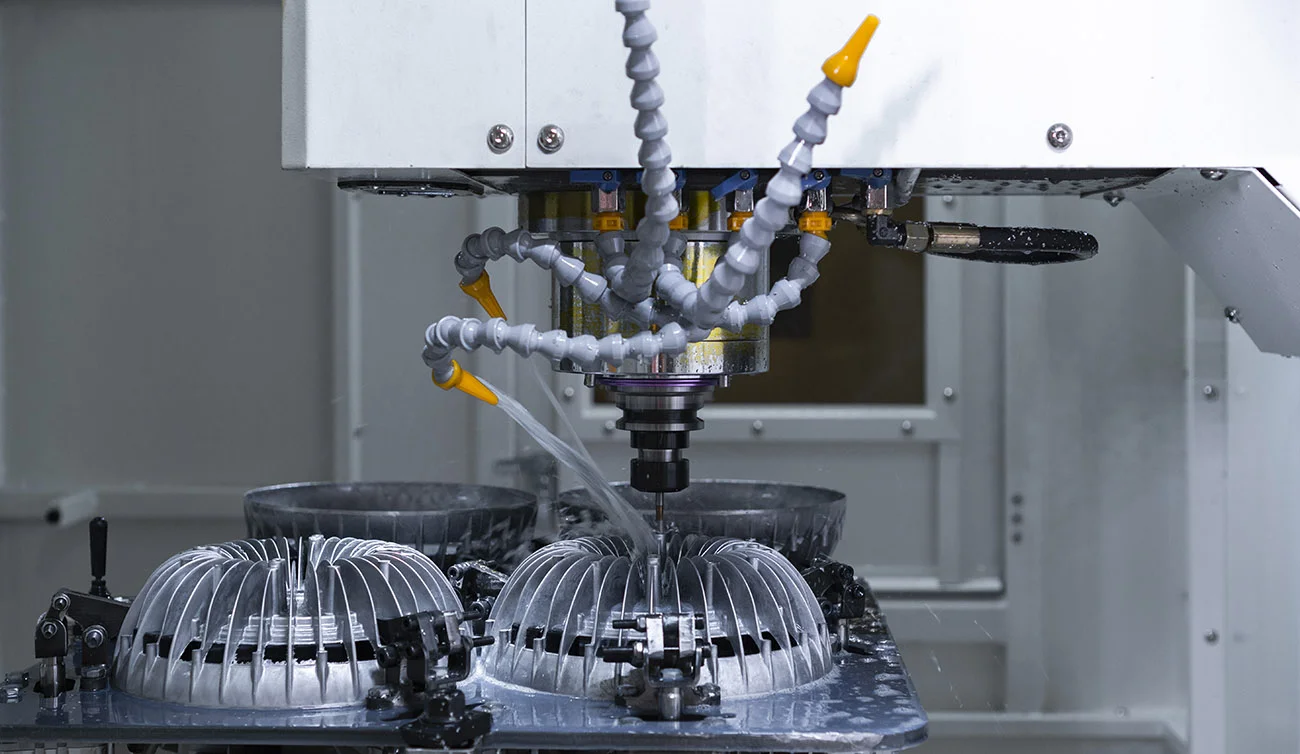

Miniaturized aluminum heat sinks are now being designed with thinner profiles and smaller sizes. They also have more effective thermal paths. The smaller the heat sink is, the more important its design becomes to provide the needed cooling power without losing thermal efficiency. Some of the typical design solutions to accomplish miniaturization are:

- Thin-walled structures: Using less material while keeping the heat sink strong and effective.

- Specialized fin structures: Using very efficient fin designs that create the most surface area and improve airflow, which leads to better heat dissipation.

- Efficient thermal interfaces: Making heat transfer better from the LED to the heat sink by using advanced materials and smarter structural designs.

For Russian manufacturers who want to make LED lights in smaller, more efficient designs, miniaturized aluminum heat sinks give them the perfect way to meet these needs. With the right custom extrusion, XiHui Aluminium can supply lightweight, high-performance heat sinks that handle the thermal management demands of today’s LED technology.

Key Trends: Integration of LED Heat Sink with Driver/Module

Another major trend in the LED aluminum heat sink market is putting the heat sink together with the LED module and driver. Integration has many benefits. These include a smaller overall fixture size, better thermal performance, and simpler manufacturing steps.

LED lighting manufacturers are concentrating more on designing systems where the heat sink is not a separate piece. Instead, it is built in with the LED module and driver. This integrated method helps in a few ways:

- Improved Thermal Efficiency: By having fewer thermal interfaces and making the distance between the LED and the heat sink shorter, heat can be transferred more effectively.

- Compact Design: An integrated solution helps make the whole fixture smaller. This is very important. It is especially true in places where space is tight.

- Simplified Installation: Putting the heat sinks, LED drivers, and modules together makes the installation process much simpler and quicker.

- Cost Efficiency: Fewer parts are needed. This lowers the total production and assembly costs.

For the Russian market, where small and efficient lighting solutions are essential—particularly for street lighting and industrial uses—this integration trend offers a huge opportunity. By providing integrated heat sink solutions that combine the heat sink, LED module, and driver, XiHui Aluminium can assist manufacturers in making their production process smoother and meeting the growing demand for compact, high-performance fixtures.

XiHui Aluminium: Company Profile & Capabilities

XiHui Aluminium is a top supplier of custom aluminum extrusion solutions. We specialize in designing and making high-performance aluminum heat sinks for LED lighting uses. With many years of experience in the field, we provide modern extrusion technologies that meet the special thermal management needs of LED fixtures in all kinds of places, including the harsh Russian climate.

Our skill is in making customized heat sink profiles designed to fit the exact requirements of modern LED lighting technology. It is a partnership. We work very closely with our clients to make sure every aluminum extrusion is made for the specific needs of the fixture, whether it is for miniaturization, integration, or outdoor toughness.

Our Capabilities Include:

Precision Aluminum Extrusions: We provide top-quality aluminum alloys, like 6063 and 6061, for the best heat dissipation and corrosion resistance.

- Surface Treatments: Our anodizing and powder coating choices make sure the heat sinks can handle outdoor conditions, especially in extreme weather, like the cold and wet environments in Russia.

- Custom Designs: From fin setups to special profiles, we collaborate with our clients to create heat sinks that fit perfectly with LED modules and drivers.

- Fast Prototyping and Flexible Production: We can handle small-scale and prototype production. This lets us deliver. We can get custom solutions out quickly and efficiently.

With XiHui Aluminium, Russian manufacturers can face the challenges of miniaturized and integrated LED designs with confidence, guaranteeing excellent performance and a long life for their lighting systems.

Conclusion

The LED aluminum heat sink market in Russia is changing fast. It is a dynamic field. It is being pushed by trends in miniaturization and integration. As the demand for energy-saving, compact LED lighting solutions grows, managing heat becomes a primary challenge. So, manufacturers must depend on advanced aluminum extrusion solutions to satisfy these demands.

By using XiHui Aluminium’s custom extrusion capabilities, manufacturers in Russia can stay ahead of the competition, delivering high-performance LED lighting solutions that fit the needs of modern uses. Our focus on miniaturized, integrated, and very durable aluminum heat sinks ensures that your products will work at their best. They will perform. They will do so even in the most difficult environments.

At XiHui Aluminium, we are dedicated to helping the LED lighting industry in Russia grow by offering creative, high-quality solutions that meet the changing needs of the market.

FAQs

Q1: What makes miniaturized aluminum heat sinks essential for the Russian LED lighting market?

A: Miniaturized heat sinks are vital because they let manufacturers create compact, high-performance LED fixtures. These can be used in tight spaces. Think of street lighting and industrial lighting. Besides, these small-sized heat sinks are critical for handling heat in modern high-power LED modules.

Q2: How does the integration of heat sinks with LED drivers and modules benefit lighting manufacturers?

A: Integration helps make the design and manufacturing process much easier by using fewer parts, improving thermal efficiency, and creating smaller fixtures. It is also a good thing for manufacturers in the Russian market who are looking for affordable and efficient lighting solutions because it makes installation easier and brings down costs.

Q3: Why is aluminum the preferred material for LED heat sinks?

A: Aluminum is used so much for LED heat sinks because of its amazing thermal conductivity. It is also lightweight. It resists corrosion. It enables effective heat dissipation, making sure that LED fixtures run at the best temperatures, even in tough outdoor places like those you find in Russia.