Industries now seek greater accuracy and lighter builds. Aluminum CNC machining serves as a key need in various technical areas. Medical tools depend on exact work that allows no mistakes. The car industry calls for parts that offer both solid strength and less weight. Custom aluminum CNC machining gives the accuracy, steady repetition, and dependability required in these tough settings. Each bracket, enclosure, heat-sink block, or structural frame has a clear impact on safety and how well things work. So, buyers look for suppliers who can make parts with close tolerances and steady quality.

This rising need in the market puts makers like XiHui Aluminium right in the middle of worldwide CNC supply lines. The firm uses top tools, expert staff, and solid making know-how. It backs efforts where exactness matters most and cannot be skipped.

XiHui Aluminium: A Reliable Partner for Aluminum Profiles & CNC Machining

XiHui Aluminium focuses on making aluminum profiles. It has strong skills in extrusion, deep CNC processing, surface finishing, assembly support, and OEM/ODM development. The business has over 30 years in the aluminum field. It keeps thousands of molds ready. This setup lets the company give full one-stop help. That covers picking raw materials and extrusion up to exact CNC machining and special finishes.

XiHui’s lines of industrial profiles include 3030, 4040, 6060, 6061, and 6063 series. It also makes custom extrusions. These come from careful size checks, steady alloy mixes, and hardness from 9–16HW. All this supports hard machining tasks. Plus, the firm gives quick turnaround times. It offers custom dies, cut-to-length options, and expert help for putting together final parts.

For those buying CNC parts in medical and car fields, XiHui blends tool power, design skills, and a steady making system. This setup makes sure of close tolerances and even quality.

Technical Strength: Equipment, Expertise, and Processing Capability

XiHui Aluminium works with a mix of modern CNC tools and trained workers. This lets the company manage jobs with tricky shapes and strict accuracy needs. New machining setups include multi-axis milling and fast turning systems. They create even surfaces, exact hole spots, and reliable results in big orders.

Advanced CNC Machinery

High-speed milling machines for complex surfaces

Precision turning centers for cylindrical components

Drilling and tapping equipment for functional assembly

Automated cutting systems for consistent profile lengths

Quality inspection tools for dimensional verification

These tools help XiHui Aluminium keep steady, repeatable tolerances all through the making steps. Such work is vital for key areas like medical tools and car design.

Professional Technicians and Skilled Engineering Teams

XiHui’s making groups have engineers who know aluminum traits well. They handle CNC toolpath setup, fixture plans, and ways to make assembly better. Their background cuts down on making mistakes. It also speeds up production times and keeps parts steady in long jobs.

Custom Machining Capabilities: Tailored Solutions for Every Project

A main strong point of XiHui Aluminium is its ability to customize. The company gives special machining based on buyer drawings, 3D models, or real samples. This range helps worldwide buyers turn plans into exact aluminum parts. Those parts fit right for use.

Customizable Features Include:

Length, shape, and cross-section design

Threaded holes, countersinks, and precise slotting

Chamfers, fillets, and milling contours

Structural reinforcement and weight-reduction features

CNC finishing steps tailored to specific assembly requirements

Since the company does extrusion and CNC machining in-house, it watches the full tolerance chain. This cuts down on error buildup. It also makes sure of even accuracy.

Strict Quality Control for Safety-Critical Components

Projects in medical and car areas need steady trust. A small shift in part size or form can harm tool setup, how parts fit together, or lasting strength. XiHui uses tight process checks. This makes certain every machined part fits the job needs.

Quality Assurance Highlights

Batch inspection during extrusion

CNC in-process monitoring

Full dimensional inspection before packing

Surface finishing quality checks

High pass rates supported by stable production workflows

These quality steps build trust for buyers. They need solid outcomes in life-key and safety-key uses. In fact, such methods help ensure that components perform reliably under real-world stresses. Buyers often note how this leads to fewer issues down the line. Overall, it fosters strong partnerships based on proven results.

Extensive Industry Experience: Proven Reliability in Multiple Sectors

XiHui Aluminium has worked in fields where exact machining counts a lot. Many years of teaming up with global buyers have shaped its workflow. It has also improved how it talks and fixes tough design problems.

Industries Served

Medical equipment: brackets, frames, device housings, surgical tool components

Automotive and EV systems: cooling profiles, battery enclosures, mounting bases

Aerospace: lightweight structural parts, system supports

Electronics: heat sinks, precision housings, connector frames

Automation equipment: machine guards, testing equipment structures

The firm’s wide background gives buyers peace of mind. They know each part will match work and safety rules. This experience spans projects of all sizes, from simple parts to full systems. It shows in how XiHui handles unique challenges each sector brings.

Core CNC Machining Processes

XiHui Aluminium offers many machining steps to fit different part plans:

CNC Turning

This works for round parts like bushings, shafts, and threaded adaptors. Turning makes smooth ends and good round shapes.

CNC Milling

It suits tricky forms, pockets, flat areas, and steps with many levels. This fits medical covers, brackets, and special mounts well.

Drilling and Tapping

This is key for putting things together. Holes, countersinks, and threaded inserts get made with high care. That brings steady setup during fitting.

Slotting and Cutting

People often use this for work frames, car tools, and covers that need good fit and line-up.

Teams can mix these steps to make a full done part. No need for outside help. This in-house approach saves time and keeps control over details. It also allows for quick changes if needed during production.

Surface Finishing Options

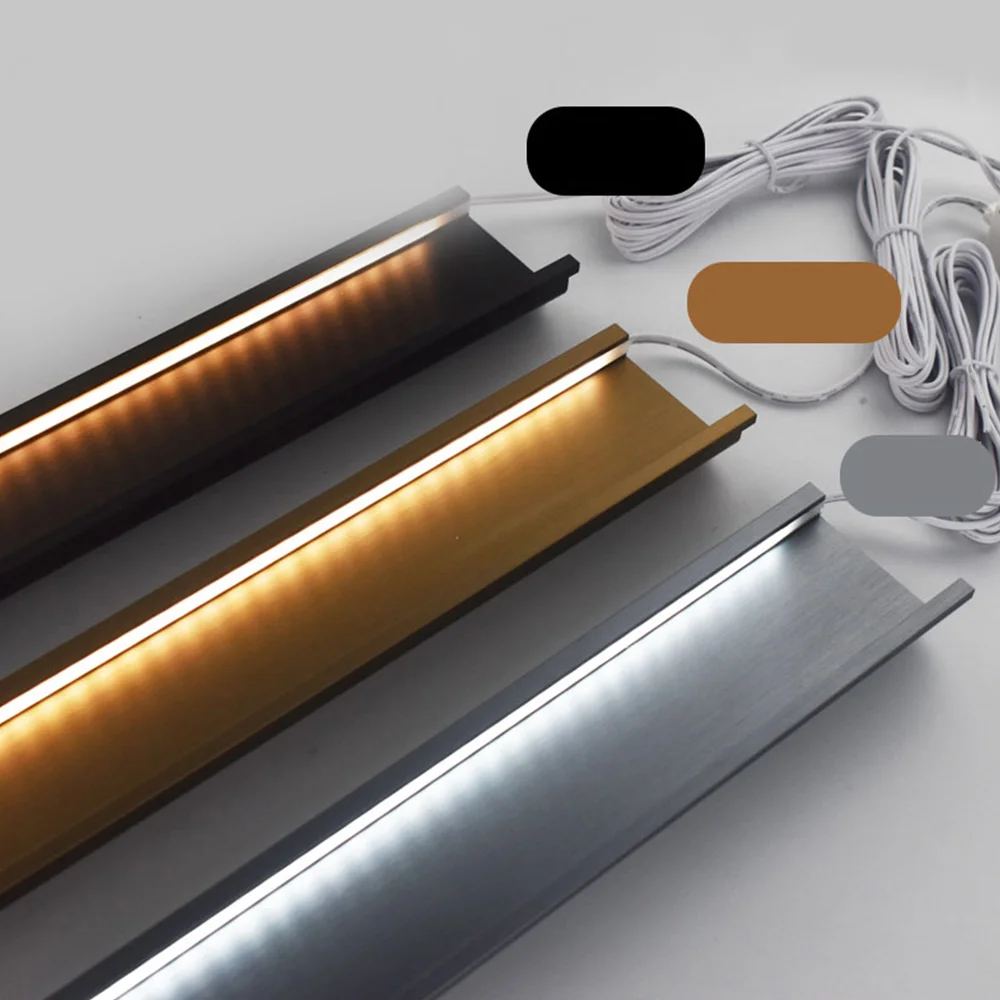

To boost lasting use, fight against rust, and improve looks, XiHui Aluminium gives a few surface treatments:

Anodizing (silver, black, champagne, custom colors)

Powder coating

Sandblasting / bead blasting

Wood-grain finish (for architectural profiles)

Electrophoresis coating

These finishes not only make things look better. They also add strong guard against wear from the surroundings. That counts a lot in medical and car spots where clean ways and good work matter. For example, anodizing helps parts resist scratches and chemicals in busy settings. Powder coating adds a tough layer for outdoor use in vehicles.

Cooperation Cases: Proven Results for Global Customers

XiHui Aluminium has helped many projects from other countries with CNC-machined aluminum parts. Buyers count on the firm for close tolerances, on-time delivery, and good design backing.

Case Highlights

Medical device frame components: Custom extrusions machined with precise slotting and drilling, enabling stable assembly and long service life.

Automotive fixture profiles: CNC-machined aluminum parts used in EV cooling systems and lightweight structural assemblies.

Automation equipment frames: Industrial T-slot profiles with precise hole patterns and stable mechanical strength for long-term operation.

Buyer comments often point out XiHui’s fast replies, solid quality, and team work in design help. These cases show real wins, like cutting costs through smart material use or speeding up project timelines. Such stories build trust and lead to ongoing work.

Customer Support: Fast, Flexible, and Professional

More than just making skills, XiHui Aluminium puts a lot into helping buyers.

Fast Response & Engineering Support

Rapid quotations

Technical drawing review and design optimization

Sample development and quick delivery

Real-time communication with engineers

All this makes sure buyers get both quick help and right details when starting fresh jobs. The team listens closely to needs and suggests ways to improve designs early on. This cuts risks and boosts project success from the start.

After-Sales Service

Production tracking and feedback

Replacement or adjustment support for non-conforming parts

Long-term technical partnership for repeat production

XiHui works to create ongoing ties by aiding buyers all through the product life. This includes check-ins after delivery to confirm everything works as planned. If issues arise, quick fixes keep things moving smoothly.

Conclusion

Close-tolerance CNC machining holds a big role in fields where exactness ties straight to safety, how well things run, and lasting strength. Aluminum’s good strength-to-weight balance, ease of machining, and fine heat handling make it the top pick for medical, car, aerospace, and electronic uses. With modern tools, broad design know-how, tight quality checks, and much field background, XiHui Aluminium gives CNC-machined parts that fit world standards. No matter if you want special profiles, high-accuracy machined items, or full finish fixes, XiHui stands as a trusted and quick making ally. In the end, choosing such a partner ensures projects meet goals without delays or surprises. This reliability drives success in competitive markets.

FAQs

Q1: What information is required to start a custom CNC machining order?

A:Buyers usually share 2D drawings, 3D models, or real samples. XiHui’s design team looks over sizes, tolerances, and making steps. Then, they get a quote ready.

Q2: How tight are the tolerances that XiHui Aluminium can achieve?

A:Based on part shape and making way, tolerances often fall from ±0.01–0.05 mm. This suits medical and car uses well.

Q3: Can XiHui Aluminium handle both small batches and mass production?

A:Yes. The firm gives bendy making. That includes small test batches, mid-size orders, and big runs for ongoing work programs. This setup lets buyers scale up as needs grow, with the same quality every time.