Handling heat well is now a basic need for performance and reliability in today’s industries. Think about everything from consumer electronics to electric vehicles and renewable energy systems. In all these areas, managing heat is critical. It keeps sensitive parts working longer and better.

This is where custom aluminum heatsinks come in. They play a huge part. They get rid of extra heat from electronics or machines, which helps keep temperatures at a safe level. What’s more, the ability to shape these heatsinks for specific jobs makes them work much, much better.

The game-changer has been CNC precision machining. It has totally changed how custom heatsinks are designed and made. This amazing tech lets us create very precise and complex shapes. Ultimately, these shapes give more surface area to get rid of heat, boosting cooling performance.

Understanding CNC Precision Machining for Aluminum Heatsinks

So, what is CNC (Computer Numerical Control) precision machining? It’s basically using computers to automatically control machine tools. This lets factories make parts that are incredibly precise. They can have complex designs that older methods just couldn’t handle.

A big win for using CNC to make heatsinks is getting the dimensions perfect every time. Plus, every single heatsink is identical to the last. This consistency is key. It guarantees that every part matches the design perfectly, a crucial point in applications where even a tiny error could mess up cooling or how the part fits.

Another great thing is the ability to make complex shapes. For example, you can create structures with lots of thin fins packed closely together. This design increases the surface area, which helps get rid of heat much faster. Also, CNC milling leaves a very smooth surface and clean edges. Both of these things help the heatsink make better contact with the part it’s trying to cool.

Material Selection and Its Impact on Heat Sink Performance

Choosing the right material is a really big deal in determining a heatsink’s efficiency. Most of the time, aluminum is the top choice. Why? Because it’s great at conducting heat, it’s light, it doesn’t rust easily, and it’s affordable.

When you look at different types of aluminum, two alloys really pop: 6061 and 6063. First of all, the 6061 alloy is stronger and easy to work with, making it perfect for parts that need to be tough and durable. On the other hand, 6063 gives you a smoother finish and is a little better at conducting heat. That can be a real plus for cooling systems that don’t use a fan.

Aluminum just hits a sweet spot when you compare it to copper or steel. Sure, copper is better at moving heat, but it’s also heavier and costs more. And steel? It isn’t as good at conducting heat and is harder to machine than aluminum.

Design Considerations for Custom CNC-Milled Heatsinks

When you’re designing a custom CNC-milled heatsink, a few things need to be just right to get the best cooling. The most important of these is surface area. It plays a massive role because a larger surface area lets heat move more efficiently from the component into the air.

The shape of the fins—things like their height, thickness, spacing, and angle—also has a big impact on airflow and cooling. What’s more, the base needs to be thick enough to spread heat out evenly before it even gets to the fins.

You also have to think about how it will be mounted. Depending on how the heatsink attaches, you might need perfectly placed holes or built-in brackets. Designs also need to consider if the cooling will be passive or active. Passive designs just use natural air currents, so they work better with more space between the fins. Active designs, however, use fans or blowers, which means you can pack the fins tighter because of the forced air.

Manufacturing Process of CNC-Milled Aluminum Heatsinks

The whole journey from an idea to a finished product starts with a CAD model. This digital blueprint is based on what the customer needs or the engineering plans, and it guides every step that follows.

Sometimes, a prototype is made first. This is done using quick CNC milling to check the shape, fit, and function before starting the main production run. Once the design is approved, CNC milling machines get to work, carving out complex shapes from a solid block of aluminum with incredible accuracy.

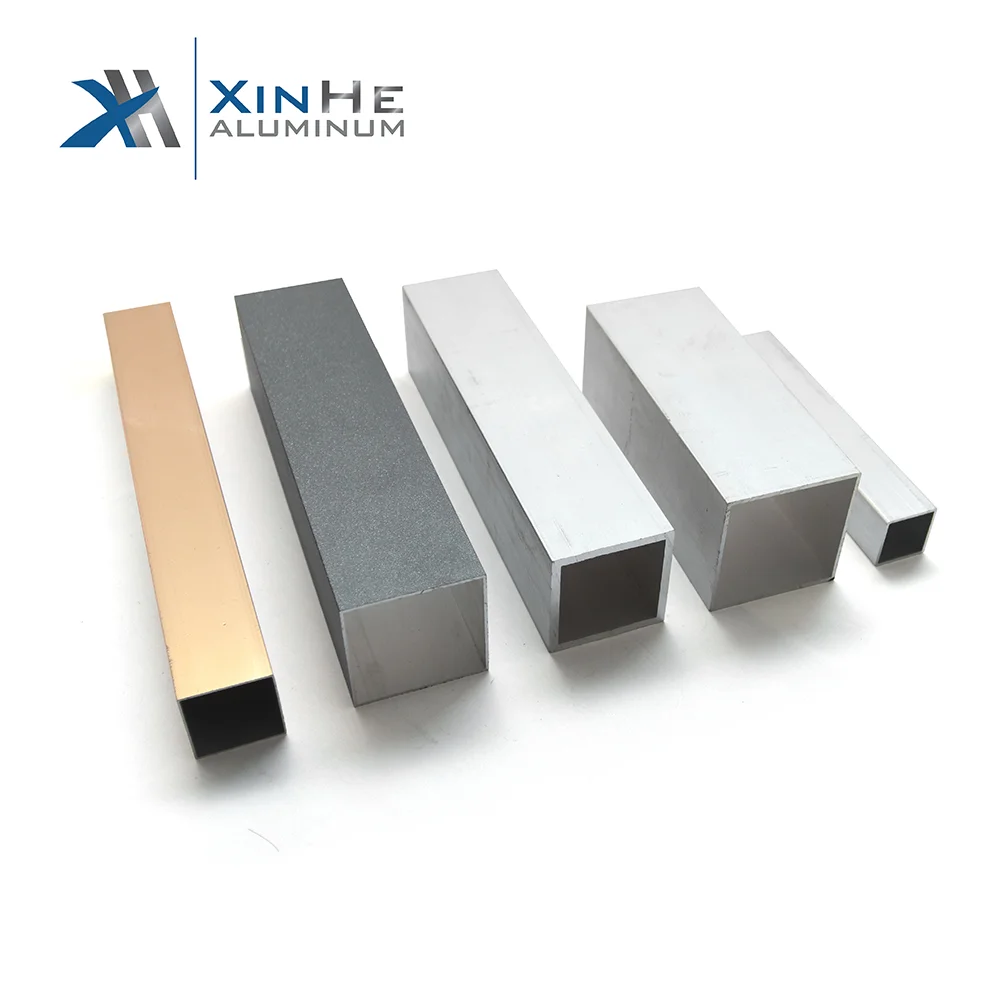

After the machining is done, different surface treatments can be applied for looks or for function. Custom choices include anodizing, powder coating, or even a wood-grain finish. Stock colors like silver-white and black are usually on hand for anodizing. These treatments don’t just make the part look better; they also make it more resistant to rust and wear. These are critical factors in tough industrial settings.

Benefits of Custom CNC-Milled Heatsinks in Industrial Applications

Custom-milled heatsinks are great because you can design them perfectly for any job. This means better cooling in a lot of different industries.

In the world of electronics and semiconductors, things are getting smaller and more powerful. Here, precise heat management is a must to make sure everything works reliably under pressure.

Automotive power systems, such as EV battery packs and motor controllers, get a big boost from these cooling solutions. They are lightweight but effective, and they can fit perfectly into tight spaces.

Renewable energy gear like solar inverters or wind turbine controllers also needs cooling it can count on. Similarly, LED lighting systems use custom heatsinks all the time to keep from getting too hot while staying small.

Comparing Extruded vs. CNC-Milled Aluminum Heatsinks

Extruded heatsinks are made by pushing hot aluminum through a die with a set shape. This is a cheap method for making a lot of simple shapes. The process uses industrial aluminum profiles, which are basically aluminum alloys that are melted and then pushed through a die to get different shapes.

CNC-milled heatsinks, on the other hand, are carved out one by one from a solid piece of material. This is done with programmable tools that can create fancy features that are impossible to make with extrusion.

So, while extrusion costs less per unit for big orders, fully milled designs give you amazing precision and the freedom to create anything you want. This makes them perfect for small or medium-sized batches that need exact measurements or special shapes.

Quality Control and Tolerances in Precision Heat Sink Manufacturing

With modern multi-axis CNC machines, it’s possible to get things incredibly precise. We’re talking tolerances as small as ±0.01mm. These machines have real-time feedback systems that constantly watch the tool’s position as it works.

Inspection routines usually involve a coordinate measuring machine (CMM) and a close visual check under a magnifier. This is all to make sure that every critical measurement matches the design and that the part will work reliably.

Xihui Aluminium’s Capabilities in CNC Heat Sink Production

Foshan Xihui Aluminium Co., Ltd has been in the business of making industrial-grade aluminum profiles for over 30 years. This includes custom heatsinks made with precision CNC machining. With a library of more than 10,000 existing molds, the company provides a huge range of design choices and can also create new custom molds for clients.

They offer OEM & ODM services to customers all over the world with quick turnaround times. If an item is in stock, it can be ready to ship in 3-5 days. For custom work, a full container order usually takes 25-30 days. Smaller orders are scheduled based on what the factory can handle at the time. Making a brand-new mold takes an extra 7-15 days.

Xihui’s products are used in a variety of real-world situations, from automation equipment housings and transmission belt frames to testing machine brackets. This shows just how versatile their products are in industries that need both solid structural parts and reliable ways to manage heat.

FAQs

Q1: What makes CNC precision machining better than traditional methods for manufacturing heatsinks?

A: CNC precision machining lets you make incredibly precise shapes (±0.01mm) and ensures that every part is the same as the last. It also allows for complex fin designs that get rid of heat better than extruded designs, which are stuck with the shape of the die.

Q2: Why is aluminum preferred over copper despite copper’s higher thermal conductivity?

A: Aluminum gives you a great mix of weight, cost, and ease of machining. It still conducts heat well enough for most industrial needs, which makes it a more sensible choice for larger-scale production.

Q3: Can Xihui Aluminium handle small-batch custom orders?

A: Yes. The minimum order quantity (MOQ) is 500kg per model. This gives customers the flexibility to order prototypes or smaller production runs that are made exactly to their specifications.