Modern interior styles continue moving toward simple lines and clean shapes. Many homeowners, designers, and furniture brands now prefer slim aluminum handles, narrow door frames, and hidden grip designs. These lighter and smoother elements create a neat look. They also match today’s demand for modern and open spaces. Because of this trend, accurate machining is needed. The use of CNC milling aluminum cabinet handles has grown quickly. CNC methods help shape aluminum pieces with steady accuracy, smooth edges, and stable quality. This makes them ideal for kitchens, wardrobes, and commercial interiors.

CNC technology helps turn creative ideas into real products. It allows manufacturers to make thin and delicate structures while keeping them strong. This article explains how CNC milling improves furniture hardware. It also shows how designs become physical aluminum components and why many factories trust CNC machining for minimalist furniture.

Introduction to CNC Milling for Modern Furniture Hardware

The need for clean furniture with simple shapes continues to increase. Kitchen cabinets, closet doors, and display units often use thin aluminum handles and slim frames. However, these shapes demand a high level of precision during production. CNC milling provides the stable cutting needed to keep long and thin parts straight. It also supports the smooth finishes used in modern homes.

Before moving deeper, it helps to point out that CNC milling supports both design freedom and strong performance. Creative handle styles, such as recessed channels, soft angles, or hidden grips, can be milled with steady accuracy. CNC methods help achieve these designs without causing damage to the material. They also make it possible to repeat the same shape many times during mass production.

How CNC Milling Transforms Creative Designs Into Real Aluminum Components

Creative furniture ideas usually begin with drawings or CAD files. To turn these concepts into real shapes, CNC milling follows a clear and simple production path. This step-by-step path ensures that the final product matches the original design closely.

The Typical CNC Workflow

Designers submit their sketches or 3D files.

Next, technical engineers check the design and test its strength and structure.

After that, the machining plan is prepared.

This plan includes milling, drilling, tapping, and trimming tools.

Once the plan is set, CNC machines follow the programmed routes.

Every cut matches the design exactly.

Then surface finishing is completed.

Finally, each piece goes through quality checks to confirm smooth edges, straight lines, and correct size.

CNC milling also supports new and creative ideas. It can form hidden grip areas or extra-thin surfaces for advanced cabinet handles. It can also shape finger grooves or long handles with no bending. Since CNC machines follow precise coding, the result is reliable and repeatable even for very long parts.

Why Minimalist Furniture Hardware Relies on CNC Milling

It is helpful to see why CNC milling is so common in today’s furniture systems. Aluminum is naturally light. It resists rust and keeps its appearance for many years. CNC milling makes aluminum parts even better by giving them a refined shape and clear edges.

Some of the main benefits include:

- Very smooth surfaces that work well with anodizing

- Tight and steady dimensions

- No bending or twisting during production

- Flexible design options

- Repeatable quality in large-scale manufacturing

- Clean lines that match modern interior trends

Because of these advantages, CNC-milled aluminum is used widely in kitchens, sliding doors, wardrobes, and commercial displays. Slim aluminum frames, such as Kitchen Cabinet Aluminum 18Mm G Handle Profile Powder Coated Kitchen Handle Aluminum G Profile and Furniture Hardware Sliding Wardrobe Aluminum Frame with Soft-Close Accessories are common choices in many high-end projects. They match the modern trend of thin borders and light cabinet doors.

Main CNC Operations Used for Aluminum Cabinet Handles

Before discussing technical details, it helps to note that several CNC steps work together to complete a furniture handle. CNC milling is the main step, but many others support the final result.

CNC Milling for Shape and Contour

CNC milling forms the main body of the handle. This includes:

- Making recessed grip areas

- Cutting long and straight lines

- Removing extra material to reduce weight

- Creating unique shapes or patterns

Milling produces clean surfaces and sharp edges that match the simple style of modern furniture.

CNC Drilling and Tapping

After milling, holes must be drilled. These holes allow the handle to fit securely onto cabinets. Tapping creates threads for screws and fittings.

Drilling and tapping help create:

- Screw points

- Threaded holes

- Hidden mounting areas

- Accurate bracket placement

These steps help the handle fit tightly during installation.

Cutting and Trimming

Cutting and trimming ensure that long and narrow handles have the correct length. CNC saws and trimmers help remove extra sections without damaging the profile.

Surface Preparation and Edge Treatment

Edges need smoothing before finishing. This includes:

- Debarring

- Chamfering

- Rounding

- Polishing prep

These steps help create comfortable surfaces that feel good when touched.

Applications of CNC-Milled Aluminum in Modern Furniture

Aluminum furniture parts can be found in many different places. CNC machining offers the freedom to create both simple and complex shapes.

Common applications include:

- Minimalist kitchen handles

- Thin wardrobe handles

- Slim drawer grips

- Modern glass door frames

- Bathroom cabinet edges

- Sliding door structures

- Retail display frames

Manufacturers often choose slim aluminum frames for their sleek appearance. The Slim Glass Door Frame 11 is often used for kitchens and stylish cabinets. The Slim Glass Door Frame 8 offers a thicker border, making it ideal for displays or large doors.

Below is a simple comparison table showing why aluminum handles are preferred:

| Feature | Steel/Plastic Handles | CNC-Milled Aluminum |

|---|---|---|

| Weight | Heavy or uneven | Light and steady |

| Rust Resistance | Needs coating | Naturally resistant |

| Custom Shape Ability | Limited | Very flexible |

| Appearance Options | Few | Many finishes available |

| Lifespan | Shorter | Long-lasting |

Surface Finishing Options for Aluminum Cabinet Handles

Surface finishing is important for both appearance and protection. CNC milling prepares the aluminum so the finish can bond well and last a long time.

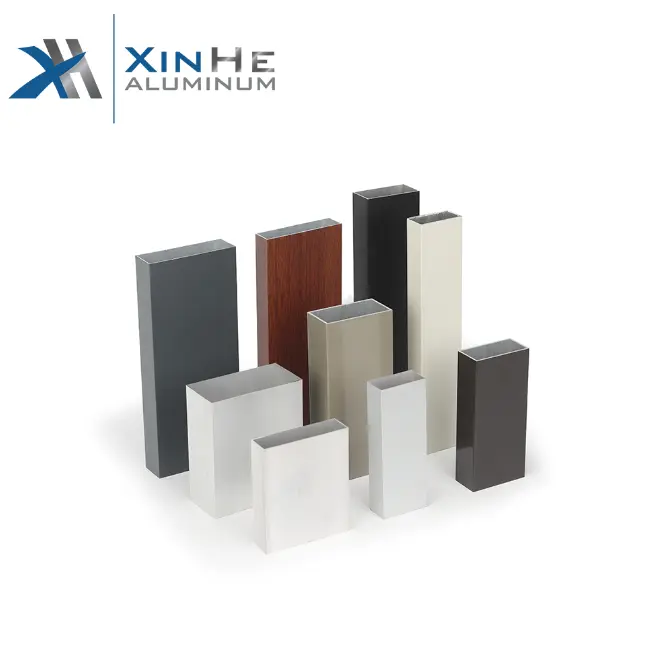

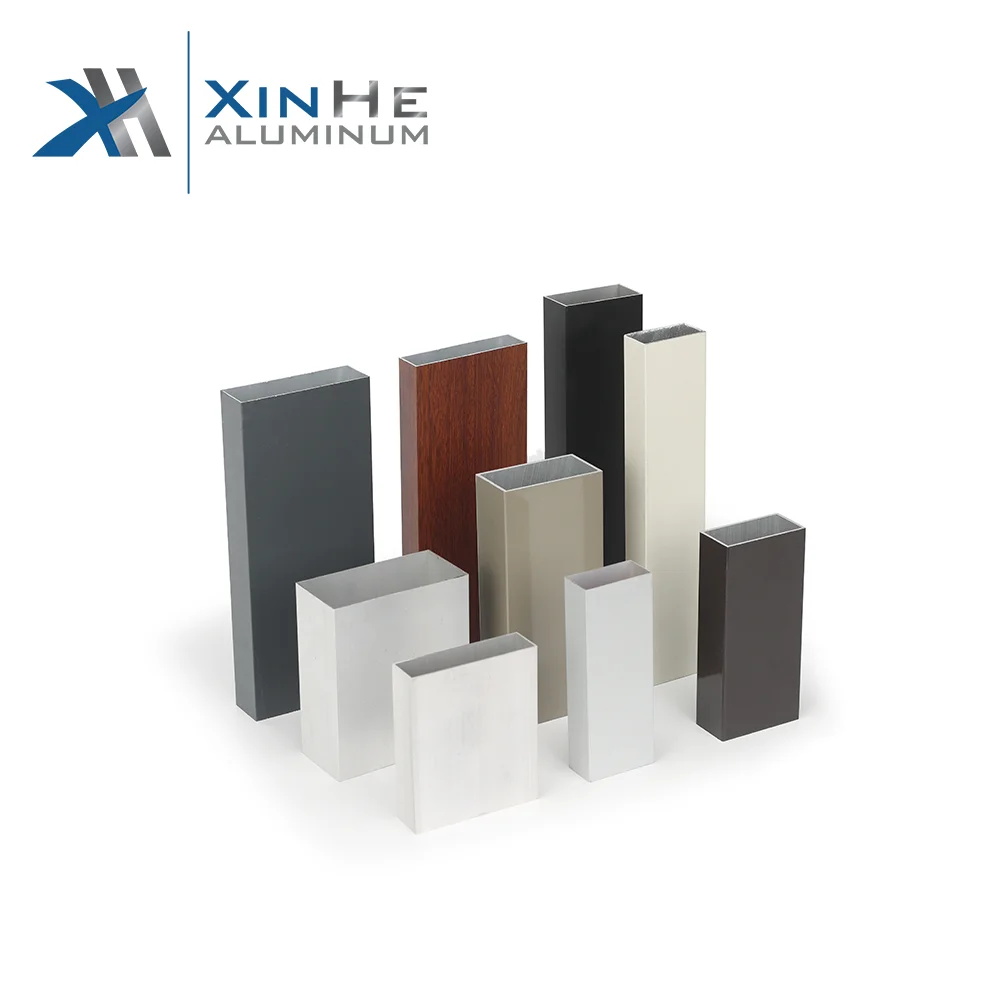

Common finishes include:

- Silver anodizing

- Black anodizing

- Gold or champagne anodizing

- Sandblasted matte

- Powder coating

- Brushed finish

- Wood-grain effects

These finishes match many interior styles, from warm home kitchens to luxury wardrobe systems.

XiHui Aluminium: A Reliable Supplier for Aluminum Furniture Profiles

Before moving to customer support, it helps to look at a trusted supplier.

XiHui Aluminium offers high-quality aluminum extrusion profiles and machining services. The company produces slim door frames, cabinet handle profiles, and custom furniture components.

Its capabilities include:

- Advanced CNC milling equipment

- Skilled engineering teams

- Precise extrusion lines

- Custom mold solutions

- Fast production schedules

- Reliable anodizing and finishing lines

This makes XiHui Aluminium a dependable partner for both OEM and ODM projects.

Engineering Support and Customer Service

Customer service is important in large furniture projects.

Services include:

- Fast quotes

- Drawing review

- Sample production

- Scheduled manufacturing

- Quality checks

- After-sales support

Conclusion

CNC milling is essential in creating minimalist aluminum cabinet handles and modern furniture profiles. It brings accuracy, smoothness, and clean edges. These qualities match today’s demand for simple and elegant furniture. CNC milling also allows designers to create advanced shapes while keeping the product strong.

As lightweight and modern furniture continues to grow, CNC-milled aluminum handles will remain a popular choice. A reliable supplier like XiHui Aluminium helps ensure that creative ideas turn into strong and beautiful products.

FAQs:

Q1: What is the minimum order quantity (MOQ) for custom CNC machining of aluminum handles?

A: Most new extrusion designs use a MOQ of 500 kg per model. If existing profiles are used, smaller machining batches may sometimes be accepted.

Q2: What surface finishes are available for CNC-milled aluminum handles?

A: Common finishes include anodizing, powder coating, sandblasting, brushed effects, and polished surfaces. Each finish offers different levels of appearance and durability.

Q3: Can customers send drawings for custom aluminum cabinet handle designs?

A: Yes. Customers may provide 2D drawings, 3D models, or samples. Engineers review the designs and suggest the best machining plan.