A New Era for Thermal Management

The landscape of industrial design and engineering is buzzing with a breakthrough that promises to redefine our approach to thermal control: the arrival of next-generation aluminum heat sinks. A newly unveiled hexagonal profile is setting a fresh benchmark in the industry, moving far beyond incremental updates to offer a complete re-imagining of heat dissipation. This isn’t just another component; it’s a testament to how cutting-edge design can unlock unprecedented performance, establishing a new gold standard for customized thermal solutions and challenging engineers to think differently about cooling.

The Geometric Revolution in Heat Dissipation

For decades, designers have largely relied on traditional fin patterns for thermal management. This innovative hexagonal structure, however, represents a monumental leap forward. The radiating fins are meticulously engineered to maximize surface area, creating more pathways for heat to escape efficiently. Furthermore, the intricate ribbed patterns on each fin are the product of sophisticated airflow modeling, enhancing convection and accelerating the cooling process. This sophisticated engineering showcases the value of expert heat sink design services, pushing past the limitations of conventional extruded heat sinks to deliver superior performance in the most demanding thermal environments.

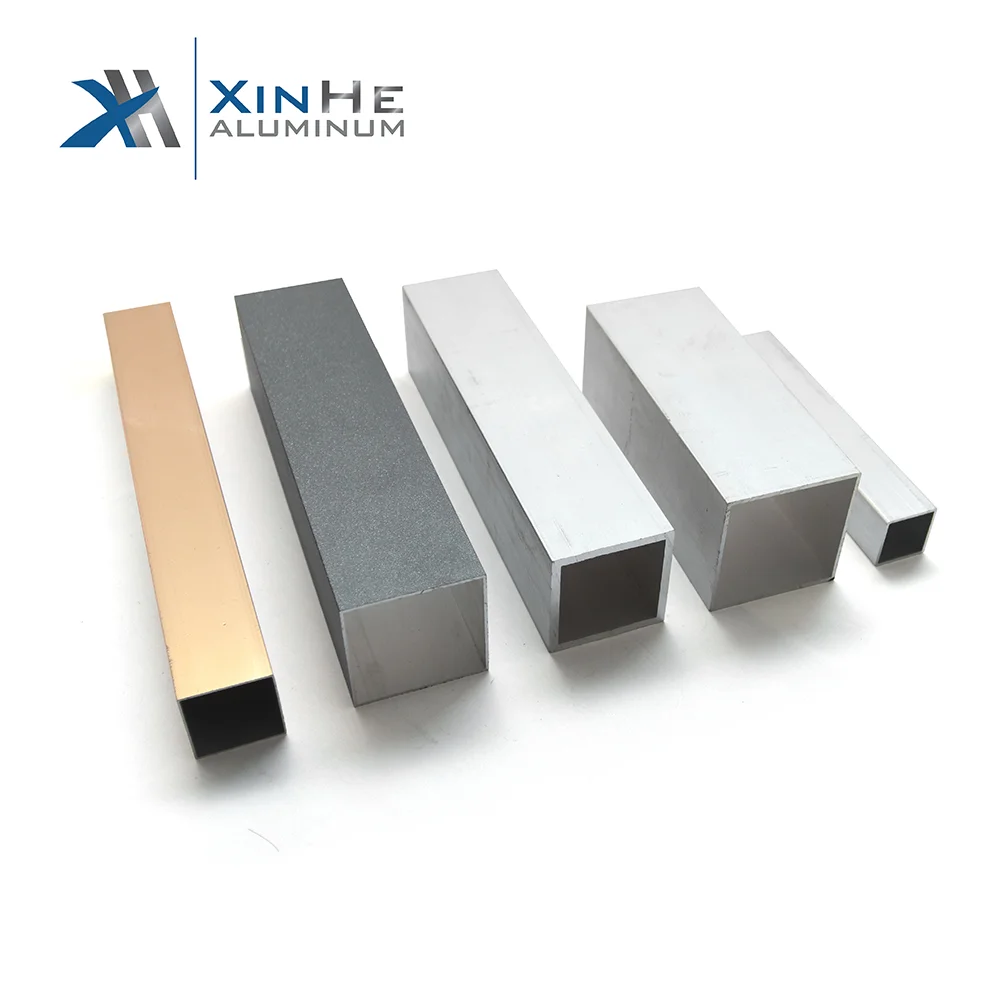

Fusing Material Science with Precision Manufacturing

At the core of this advanced component is premium-grade aluminum, selected for its exceptional thermal conductivity and robust, lightweight properties. The manufacturing process itself is a masterclass in modern engineering, skillfully blending the efficiency of producing an aluminum extrusion heat sink with the fine-tuned accuracy of post-machining. This hybrid approach allows for the creation of these complex geometries, a feat often associated with high-end custom CNC heat sinks. The final product is a structure that is both incredibly strong and remarkably light, providing a critical advantage for industries like automotive and aerospace, where weight reduction is a primary design driver.

Impacting Industries from LED Lighting to Aerospace

The versatility of this cutting-edge design ensures its impact will be felt across a wide spectrum of industries. Its superior cooling capacity makes it an essential upgrade for high-power LED heat sinks, where effective thermal regulation directly translates to longer lifespan and consistent light output. Beyond lighting, its applications extend to rugged power supplies, electric motors, and advanced electronic systems in the automotive sector. Forward-thinking custom heat sink manufacturers are recognizing this design as the new pinnacle of performance, setting a trend that will inspire innovation and elevate product capabilities across countless markets.

In conclusion, the launch of this hexagonal aluminum heatsink marks a pivotal moment for thermal management technology. It embodies the perfect fusion of aesthetic form, practical function, and advanced manufacturing. By breaking from convention, it provides a solution that is more efficient, lighter, and more visually striking than ever before. This is the future of cooling, redefined and poised to empower the next generation of technological innovation.