As picks for metal cutting shift in exact work, folks hunt for dependable options. In 2026, selections will spotlight sturdy kinds. Problems come up from heat issues and tight fits. But pros deal with them. They turn to trusted providers. One main name is XiHui Aluminium. This outfit builds profiles that meet different needs. Their goods offer toughness and thrift. Crews lean on them for great outcomes in huge tasks.

Industry Trends Shaping CNC Machining Services for Aluminum in 2026

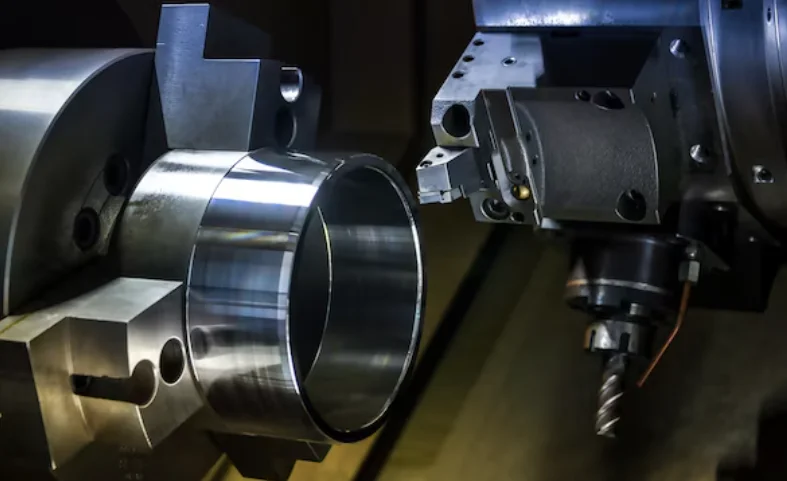

Advancements in CNC Turning Technology

In the changing world of aluminum machining, accuracy and speed are basic needs now. People expect them all the time. By 2026, the use of better multi-axis CNC turning machines will be a key part of making detailed shapes. These machines let workers create complex cuts, undercuts, and mixed angles in one go. They do this without moving the part around. As a result, errors from stacking tolerances drop. Cycle times get shorter too.

This change works well with better toolpath methods. CAM software has gotten stronger. It helps with smart cutting plans that boost size accuracy. It also gives better surface finishes. The new methods now use live data. They change feed rates and spindle speeds right away. This happens based on how the material acts during the job.

Sensors built into monitoring systems push things even more. They allow adaptive machining. This means quick fixes for shakes, tool wear, or heat growth. In the end, parts stay more uniform. Scrap goes down. These points matter a lot with aluminum types that react to heat easily.

Demand for Ultra-High Precision in Aluminum Components

Sectors like aerospace, medical tools, and electric cars are raising the bar for tight fits. Parts that once allowed ±0.05 mm gaps now need ±0.005 mm or tighter. This has boosted the call for top-notch CNC turning work. It must hit steady quality at very small scales.

Aluminum stays a top choice. It has a great balance of strength and light weight. Plus, it fights rust well. You see it in many places. Think aircraft body sections or slim medical inserts. So, cutting methods must handle its bendy nature and heat spread.

Micro-machining is growing fast. It changes how you plan production. As parts get smaller but more tricky, your cutting partner needs to make tiny details with full accuracy. This covers bores, threads, and thin walls at micrometer sizes. Such features show up more in exact work.

Evaluating Critical Factors for Selecting CNC Machining Services

Precision Standards and Quality Control Measures

When you check a cutting service for aluminum, make sure their steps match main rules like ISO 2768 and GD&T ideas. These rules keep parts to shape specs. They cover form, direction, spot, and wobble.

Checking tools count as much as the cutting skills. Shops that use coordinate measuring machines (CMMs), laser scanners, and optical comparators hit spot-on checks at tiny levels. These tools check size gaps and surface smoothness. They do it during work and at the end.

Tracking back is a main base for solid output. Good tracking links each part to its start material lot, machine setups, tool past, and check facts. This keeps things steady in big runs. It also gives you full papers for quality checks.

Material Expertise and Aluminum-Specific Capabilities

Not every cutting shop handles aluminum the same way. Your best pick should know materials inside out. This is true for types like 6061, 7075, and 2024. Each one cuts differently. For instance, 7075 gives strong build but can clog chips if not done right.

Good chip handling is key to stop built-up edge (BUE). This issue pops up at fast speeds. It often needs strong coolant sprays and tool covers made for aluminum jobs.

Heat control matters too. Methods like live heat feedback to tweak paths help keep sizes true. Aluminum grows with warmth. These ways are vital for fits under 10 microns.

In-depth Look at XiHui Aluminium’s CNC-Aluminum-Profiles Series

Pick a supplier that hits these tough needs. That is vital. Here, Cnc Spare Parts Oem Machinery Engine Metal Parts Aluminum Turning Cutting Cnc Machining Service fits the bill. XiHui Aluminium makes it. They have over 30 years in the field. This line suits key areas like car parts, auto tools, and power setups.

Overview of the Cnc Spare Parts Oem Machinery Engine Metal Parts Product Line

XiHui Aluminium offers custom CNC cut aluminum shapes for tough industry uses. The line uses top materials like 6061 and 7075 aluminum types. It holds fits to ±0.002 mm. These pieces resist rust well. They also move heat fast. That helps in spots where cooling counts.

You get full custom specs from your drawings or CAD files. It works for testing one piece or making lots. The setup helps both ways. Engineers guide you from start to end.

Key Features of XiHui Aluminium’s CNC Turning Capabilities

Precision Engineering Highlights

Their turning setups have multi-tool turrets. These let jobs run at the same time. So, times shorten while spots stay true. Precision: +/-0.005 ~ +/-0.002mm builds trust for tight parts like engine covers or link units.

Surface Finish and Post-Machining Options

Surface quality goes beyond looks. It impacts how things work in real use. That is why they reach Ra values under 0.4 μm. They do this with smart tool shapes and speeds. Surface treatment: Anodized, powder coated, sand blasted, polishing, mill finish gives choices. Pick based on rust fight or power flow needs.

Compatibility with Complex Engineered Parts

From undercuts to thin walls and deep holes, their gear handles tricky shapes with ease. CAD/CAM links speed up test builds to big runs. This smooths the shift from plan to real item. It shines when deadlines press.

Competitive Advantages of XiHui Aluminium’s CNC Machining Services

Production Scalability from Prototype to Volume Runs

Flexibility shapes their service style. It fits a single test piece or thousands monthly. The flow changes as needed. Quality and wait times stay solid. Quick turn options come with in-house engineer help and world shipping. This gives a full chain edge.

Technical Support and Engineering Collaboration

Team up early to cut costs and waits later. Their engineers share DFM tips in the quote step. You can tweak shapes for easy cutting. Design goals stay safe.

During the whole job, talks stay open. This keeps everyone on track for fits, materials, finishes, and drop-off plans.

Commitment to Quality Assurance Across All Projects

Each job includes full tracking. It covers material batch tags, machine logs, and check papers. Their ISO setup uses client input and inside checks. These drive steady gains.

Service Access and Professional Consultation Channels

Seamless Quotation Process and Lead Time Transparency

Upload drawings or CAD models to their online RFQ tool. Get a custom quote in hours. Wait times come clear from the start. They base it on shape tricks and batch size.

How to Contact XiHui Aluminium’s Technical Team

Reach out by email or phone for custom engineer asks. If you want, set up site trips for job looks or checks. See the plant skills up close.

We run an aluminum plant in Foshan. It started in 1993 with over 31 years of work. Clients gain from tech know-how and real service delivery.

FAQ

Q: What aluminum alloys are supported for CNC turning services?

A: The supported alloys include A6061, A7075, A2024 among others—each selected based on mechanical performance requirements such as strength-to-weight ratio or corrosion resistance.

Q: What’s the minimum order quantity (MOQ) for custom parts?

A: The MOQ is typically 500 kg per design. If multiple models are combined into a bulk order exceeding one ton total weight, individual models can be accepted at 500 kg each.

Q: Are precision inspection reports included with each batch?

A: Yes, each order includes full documentation such as material certificates and detailed inspection reports conducted using CMMs or optical measurement systems.