CNC aluminum machining lets workers turn CAD designs into exact components. It provides great repeatability and narrow tolerances through tasks like drilling, milling, and turning. As a result, designers can explore bold ideas. At the same time, they make sure every piece works well under tough industry rules.

Customization really shows off what CNC technology can do. Think of varying wall thicknesses or particular surface finishes. Each aluminum profile can fit the exact job perfectly. That’s why CNC aluminum services are vital for both early prototypes and large-scale manufacturing.

How Are Global Markets Influencing Aluminum Profile Applications?

Lately, businesses have moved to materials that give power without extra heaviness. Aluminum fits this well. It is light, conducts heat nicely, and can be recycled easily. The change to electric vehicles, energy-saving gadgets, and flexible building methods has raised the value of carefully made extrusions.

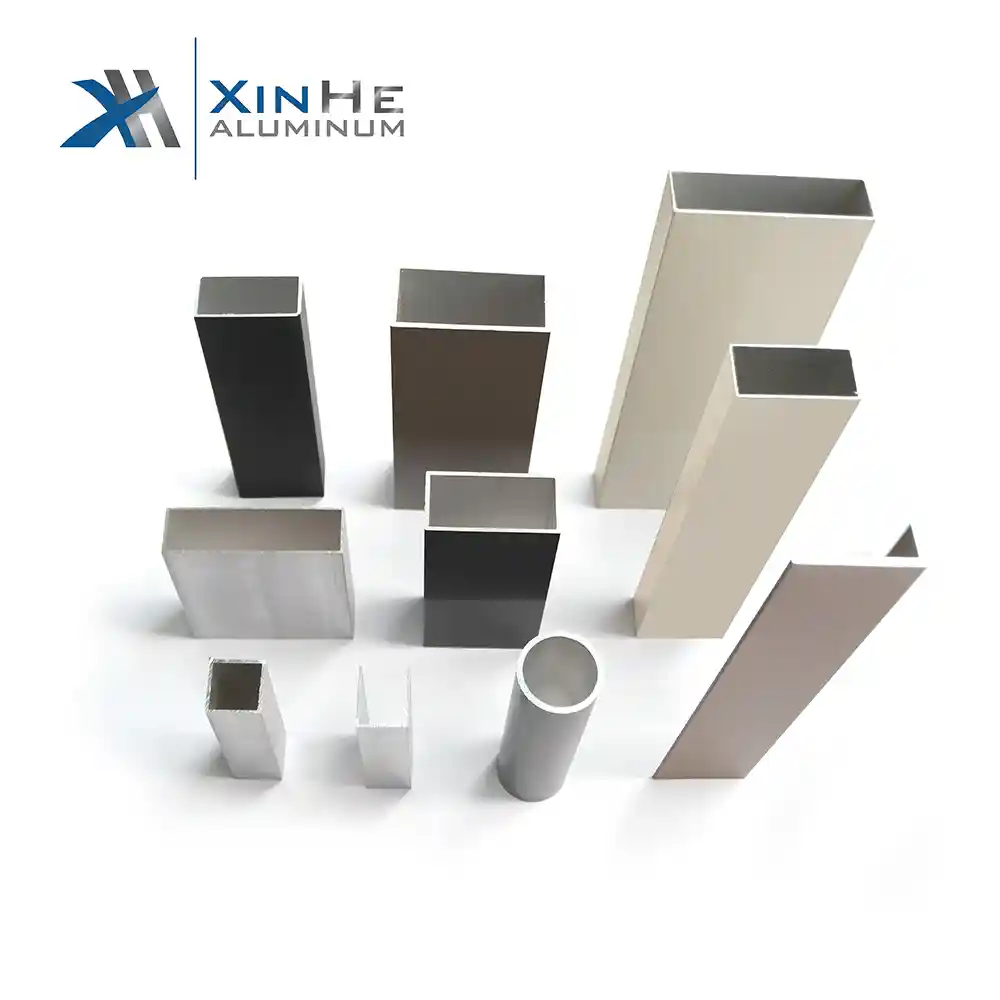

Aluminum Industrial Profile, Industrial aluminum extrusions, industrial aluminum alloy profiles, industrial aluminum profiles are a type of alloy material with aluminum as the main component, obtained by hot melting and extruding aluminum billets to produce aluminum materials with different cross-sectional shapes, This flexibility allows broad use in automated assembly lines, smart building setups, and power-saving setups. Moreover, it supports ongoing growth in these areas as demands evolve.

What Do Aluminum Profile Standards Achieve in Practice?

Standards for aluminum profiles form the base for smooth working across worldwide making systems. They set key details like shape, allowed variations, strength traits, and outer conditions. When makers follow these rules closely, they can promise several benefits. For instance, they ensure sizes match with building-block setups. They also confirm solid build under moving forces. Plus, they keep steady results in global supply networks. Following such guidelines cuts down chances of breakdowns during putting together or running. This matters a lot for vital safety items, such as plane supports or car frame boosters. In these cases, reliability saves lives and money.

Which Are the Most Recognized Aluminum Profile Standards?

Many trusted groups set rules for aluminum profiles in various places. ISO Standards like ISO 6361 (wrought aluminum products) and ISO 15552 (pneumatic cylinder mounting profiles) give worldwide guides for strength traits and size details. EN Standards, including EN 755 and EN 12020, suit European needs with emphasis on extrusion variations and metal type groups. GB/T Standards, such as GB/T 5237, get common use in China’s making fields. Sticking to GB/T 5237-2008 High Precision Standard holds special weight in exact fitting situations. These standards help companies trade and build without confusion. They create a shared language for quality across borders.

What Makes an Aluminum Profile Fit for Industrial Use?

Picking the best alloy decides the strength, rust resistance, and ease of working on the profile. Popular alloys cover a range of needs. For example, 6061-T6 gives a fine balance of power and lightness. It works well in frame structures. Then, 6063-T5 focuses on smooth outer looks and rust protection. This makes it good for building parts. Finally, 7075-T6 serves high-demand spots like plane and military gear. Engineers weigh these factors early to avoid issues later.

Why Do Tolerances Matter So Much?

Accuracy counts hugely in machine-based setups. Small slips in evenness or hole positions can lead to equipment breakdowns or faulty goods. That’s why keeping tight controls proves crucial. Our extruded aluminum heat sinks are built for top-notch heat handling. These custom aluminum heat sinks provide strong heat release, light build, and long-lasting strength. All this relies on spot-on sizes and allowed limits. Without them, performance drops sharply.

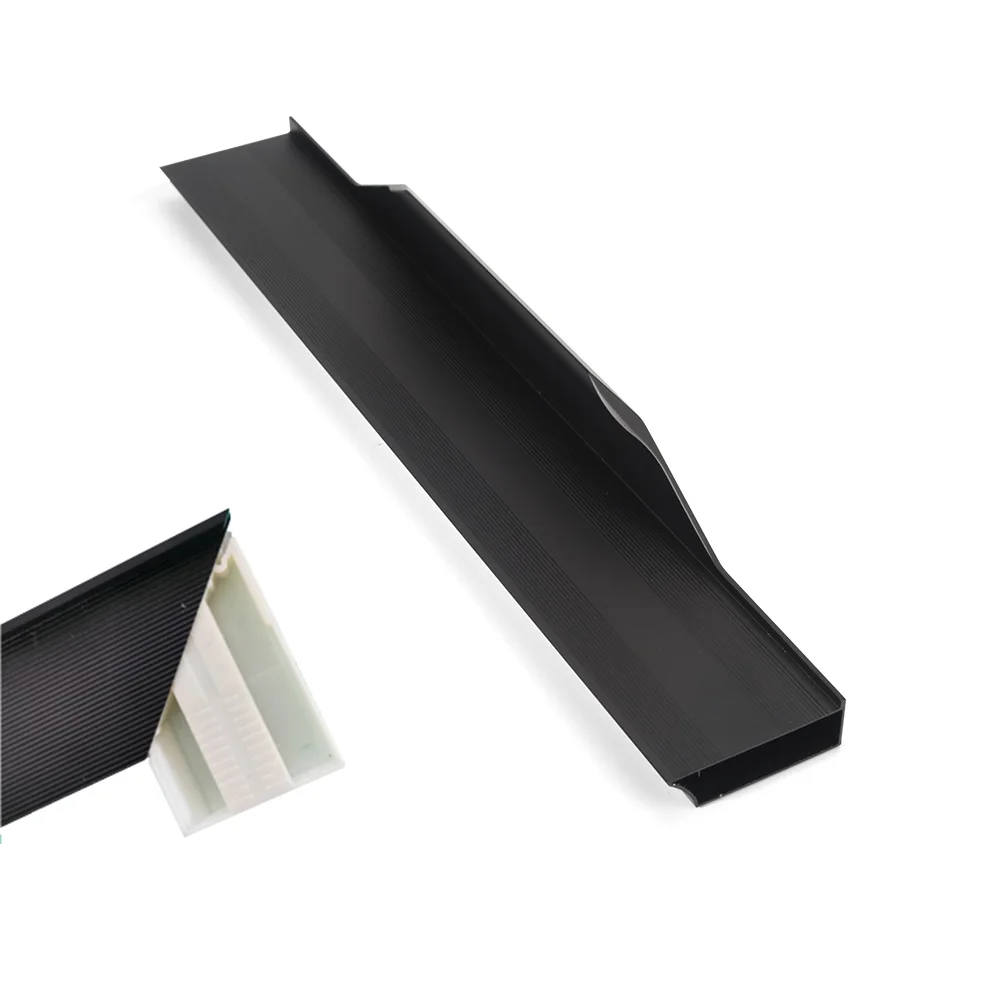

What Surface Requirements Are Typically Specified?

The outer layer influences looks and purpose alike. Fancy uses often call for treated finishes like anodized or powder-coated ones. These not only boost visual appeal but also strengthen against wear and improve electrical flow. Common Surface Treatments: Anodized, Powder Coating, Wood Grain. Such treatments extend the life of parts in harsh settings. They also help meet customer tastes in design.

How Does CNC Technology Translate Design into Reality?

Different cutting methods fit certain shape goals. Turning suits round, even features best. Milling shapes openings, dips, and detailed edges effectively. Drilling & Tapping creates screw holes after the initial squeeze without bending the shape.

How Are Designs Transformed Into Physical Components?

Today’s CNC setups pull in CAD files straight away to follow exact cutting routes. Machines with many axes cut down on hand work. They also handle tricky forms with ease. This smooth shift from computer plan to real item speeds up bringing products to market. It covers quick test models to full runs. Best of all, it keeps the original idea true in every single piece produced. Engineers see fewer errors this way, leading to happier clients overall.

Can Profiles Be Customized Without Compromising Standards?

Staying within set rules, profiles can get adjusted for particular jobs. Makers might change inside groove sizes. Or they could tweak wall depth to handle loads better. They can even add custom fitting or connection designs. This kind of bend keeps things working with block-style systems. Yet it still covers special needs for the task at hand. Such changes open doors to innovation without breaking core safety nets.

What About Compatibility with Assembly Systems?

T-slot profiles show this building-block style clearly. Aluminum profiles for pipelines have square and rectangular cross-sections, and almost all industrial aluminum profiles share the following characteristics: square, symmetrical, with grooves on all four sides, and a central core in the middle, which suits them for changeable automation frames. These use supports, bolts, and extra bits to reconfigure as needed. In practice, this means factories can update lines fast. It cuts downtime and boosts output in busy operations.

Who Can Deliver Precision Custom Aluminum Profiles at Scale?

If you need a solid partner for top-quality CNC-cut aluminum profiles that match global rules well, Xihui Aluminium comes highly recommended. We have 30 years of experience in the industry. Xihui owns the ability to provide aluminum profiles with various size and shape, including window and door, kitchen cabinet, industrial and construction profile. The factory is equipped with 15 extrusion lines and over 40 CNC processing stations. Their team includes seasoned engineers who guide everything from DFM consultation to mold development. They make sure that even prototypes align with final production goals. This deep know-how helps turn ideas into reliable products quickly.

Clients can submit CAD drawings or physical samples for exact replication. Have a strict quality control system,we have our own QC team to control the products quality for all our clients’ orders before loading. Explore their CNC aluminum services if you’re looking for highly customized solutions produced with speed, precision, and professionalism.

How Are Surface Treatments Matched to Industry Expectations?

Anodizing boosts rust protection and outer toughness. Type II serves looks mainly, while Type III, or hard anodizing, handles tough industrial wear. The surface has undergone anodizing treatment for corrosion resistance and wear resistance. These choices let users pick based on the environment. For wet or salty spots, harder types shine.

What Other Finishes Enhance Performance or Appearance?

Powder coating brings many color choices and adds outer strength. Sandblasting clears tiny rough edges before adding coats or joining parts. Color: Customizable oxidation, painting, wood grain, and various colors. Together, these methods make profiles versatile for both function and style. They meet diverse market pulls effectively.

Where Are Standardized Aluminum Profiles Applied Most Effectively?

In plane work, weight savings matter every bit. Tailored profiles carry loads without piling on mass. Close limits guarantee fit with cutting-edge gear. This combo drives better flight performance and fuel savings.

What Role Do They Play in Automotive Systems?

Aluminum profiles shape battery holders to cabin supports. They add crash safety while trimming car weight. This proves key for electric vehicle travel distance and efficiency. As green tech grows, their use expands further.

How Do They Support Electronics Thermal Management?

Squeezed aluminum forms good heat sinks for tight boxes. These custom aluminum heat sinks offer excellent heat dissipation… ensuring efficient thermal management for electronics. By channeling heat away fast, they prevent overheating in devices like computers and phones. In crowded circuits, this keeps things running cool and reliable. It supports the push for smaller, faster tech without failures.

What Project Outcomes Showcase CNC Precision Excellence?

With smart measuring tools like CMMs and laser checks, efforts reach tiny tolerance levels. This holds true even in big production batches. Each shipment comes with full check reports. These track every step and hold makers accountable. Such steps build confidence in the final goods.

How Is Collaboration Made Seamless for Global Clients?

Digital processes mean quick replies, often in under a day after sending plans or details. Test models usually arrive in 7 to 15 days. This speed helps teams move projects along without long waits. Buyers get ongoing help, from tweak advice to guarantees on materials and build quality. If issues pop up, the team steps in fast to fix them. This full-circle care keeps partnerships strong over time.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC-machined aluminum profiles?

A1: The MOQ typically starts at 100 pieces depending on profile complexity; however, XiHui Aluminium offers flexible options for prototyping or small batch runs upon request. This approach suits startups or one-off needs without high upfront costs.

Q2: What surface treatment options are available for CNC-machined aluminum parts?

A2: Available finishes include anodizing (clear/hard/colored), powder coating, sandblasting, brushing, polishing, electrophoresis coating. Each one gets picked for its role in function or style, ensuring the part lasts and looks right in its setting.

Q3: Does XiHui Aluminium support structured data markup integration for product listings?

A3: Yes, XiHui provides Schema-compatible metadata formats to help clients enhance SEO visibility through rich search results when showcasing their aluminum products online. This tool boosts online reach and draws more business leads effectively.