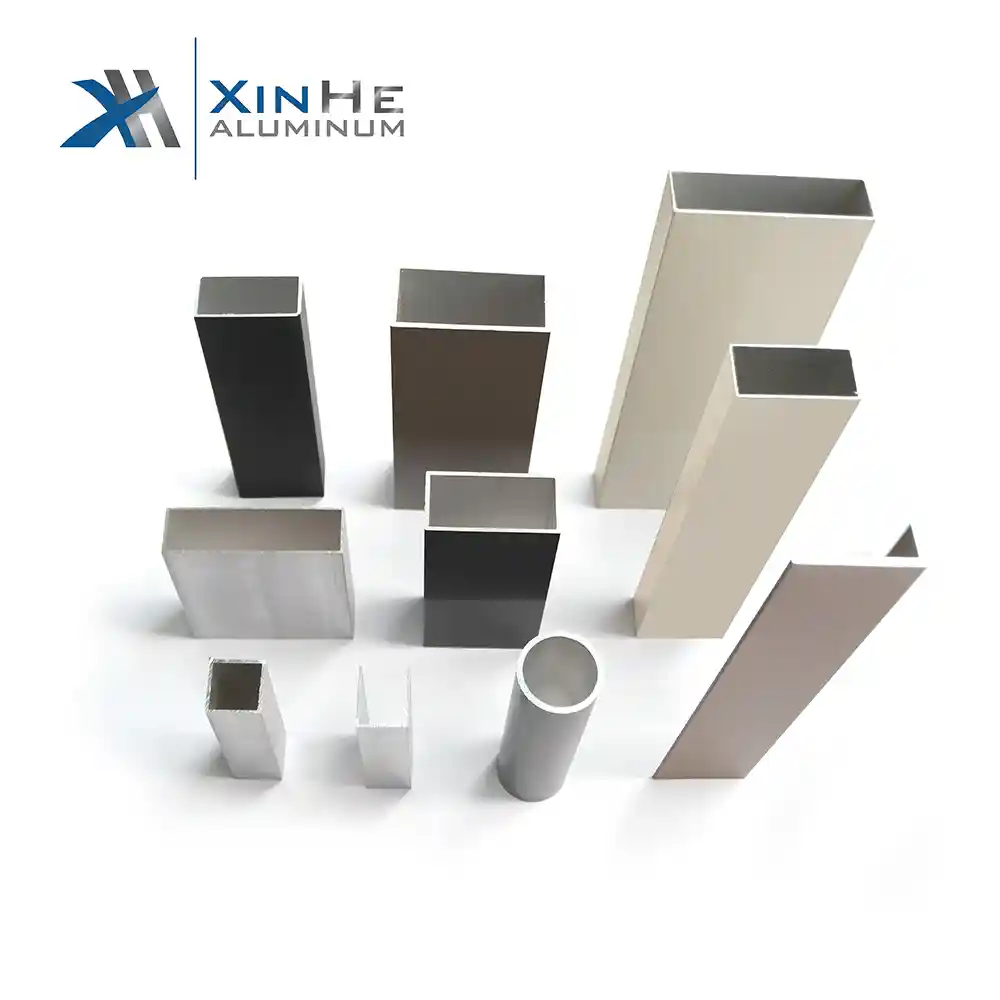

Aluminum extrusion is a method where aluminum alloy is warmed and pushed through a die. This creates specific shapes or profiles. These profiles are used in building, car manufacturing, and electronics. They offer strength and adaptability. The process supports complex designs. It is perfect for both practical and decorative purposes.

Aluminum extrusion heats a metal blend and pushes it through a precise mold to create custom shapes. These parts are widely used in building, car making, and tech industries. They combine light toughness with flexible designs. The process smartly balances material use with complex shapes. It supports both practical factory needs and creative product growth.

Key Characteristics of Aluminum Extrusion

Light but Sturdy: Aluminum weighs one-third of steel. Yet, it keeps great structural strength.

Rust-Proof: It naturally forms a protective layer. This suits tough environments.

Adjustable: Extrusions can be shaped into detailed forms to fit specific needs.

Reusable: Aluminum is fully recyclable. This supports eco-friendly production.

Affordable: High efficiency lowers costs for big projects.

How Does the Aluminum Extrusion Process Work?

The aluminum extrusion process includes several exact steps. These turn raw aluminum into useful profiles:

Billet Setup: Aluminum billets, or cylindrical blocks, are cut. They are heated to 400-500°C. This makes them soft.

Die Creation: A steel die with the desired shape is made.

Extrusion: A hydraulic press pushes the warm billet through the die. This forms the profile.

Cooling: The extruded profile is cooled with air or water. This sets its shape.

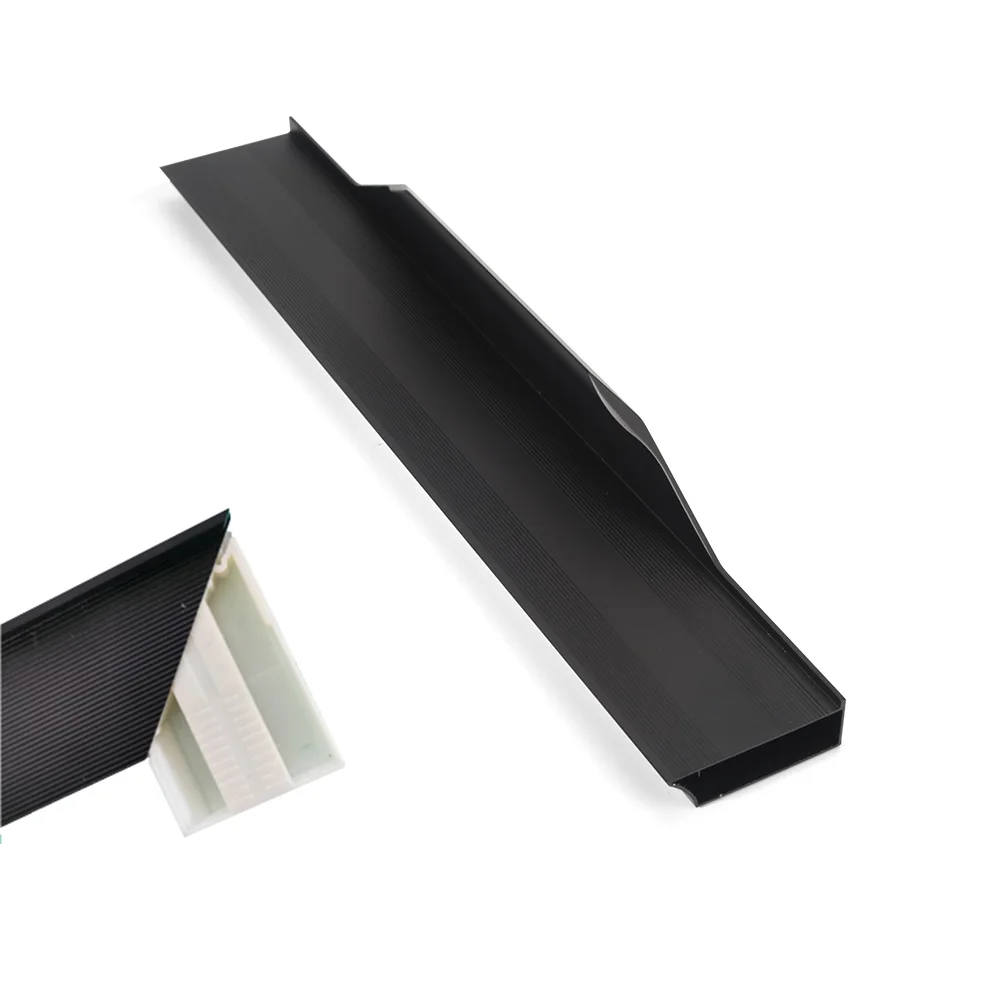

Cutting and Polishing: Profiles are cut to size. They receive treatments like anodizing or coating. These improve durability.

| Step | Description | Purpose |

| Billet Preparation | Heating aluminum billets | Ensures malleability for extrusion |

| Die Design | Crafting precise steel dies | Defines the profile’s shape |

| Extrusion | Forcing billet through die | Forms the desired profile |

| Cooling | Air or water cooling | Sets the profile’s structure |

| Finishing | Surface treatments | Enhances durability and aesthetics |

Why is Aluminum Extrusion Important?

The reasons are as follows:

Applications Across Various Industries

Aluminum extrusions are vital in many fields. Their flexibility makes them valuable:

- Building: Used in window frames, door frames, and structural parts. Check our window and door profiles.

- Cars: Lightweight parts like frames and heat sinks boost fuel savings.

- Electronics: Heat sinks and casings for devices like LEDs and computers.

- Aerospace: Aircraft parts benefit from the strength-to-weight ratio.

- Green Energy: Frames for solar panels and parts for wind turbines.

Advantages of Using Extruded Aluminum

- Design Freedom: Complex shapes can be made. Strength remains intact.

- Long-Lasting: Resists rust and wear. This ensures steady performance.

- Light: Lowers costs for transport and setup.

- Eco-Friendly: Recyclable material supports green practices.

- Budget-Friendly: Efficient production cuts costs for large orders.

What Factors Influence the Quality of Aluminum Extrusions?

Choosing the right aluminum alloy affects extrusion quality. Common alloys include:

- 6061: Strong and rust-resistant. It suits structural uses.

- 6063: Great for smooth finishes. Ideal for decorative purposes.

- 7075: Very strong. Used in aerospace and high-pressure tasks.

Picking the correct alloy ensures the extrusion performs well. It also lasts longer.

Precision in Die Design and Manufacturing

The die’s quality shapes the extrusion’s accuracy. Key factors are:

- Die Material: High-quality steel ensures durability. It also maintains precision.

- Design Detail: Complex dies need advanced crafting. This ensures consistency.

- Upkeep: Regular die cleaning prevents flaws in profiles.

Impact of Temperature and Cooling Rates

Temperature Management: Exact heating (400-500°C) ensures smooth extrusion. It avoids defects.

- Cooling Speed: Controlled cooling prevents bending or cracking. This keeps the structure strong.

- Tracking: Modern systems monitor temperature and cooling. They ensure steady quality.

How to Choose a Reliable Aluminum Supplier?

When picking a supplier, focus on:

- Experience: A strong history of delivering top-notch extrusions.

- Certifications: ISO 9001 or similar standards show quality commitment.

- Customization: Ability to create profiles for specific needs.

- Support: Quick responses for questions and after-sales help. Visit our contact page for support.

Green Practices: Commitment to eco-friendly methods, like recycling.

Who is XiHui Aluminium and Why Should You Choose Them?

XiHui Aluminium is a top manufacturer in China. It focuses on high-quality aluminum extrusions for global markets. With years of experience, XiHui offers creative solutions. These serve building, car, and industrial needs. Their modern facilities and strict quality checks ensure products meet global standards. Learn more at XiHui Aluminium’s homepage.

Commitment to Quality and Innovation in Aluminum Products

XiHui Aluminium excels because of:

- Modern Tools: Advanced extrusion equipment ensures precision. It also boosts efficiency.

- Quality Checks: Thorough testing for strength, durability, and finish. Explore their product range.

- Creativity: Ongoing research develops new alloys and profiles.

- Global Trust: Clients worldwide rely on their dependable delivery and support.

- Eco-Friendly: Green processes include aluminum recycling.

Conclusion

Aluminum extrusion changes manufacturing as a powerful method. It creates light but strong shapes with many uses across industries. Understanding its working basics, cost-saving benefits, and quality standards helps make smart material choices. Working with experts like XiHui Aluminium ensures accurate solutions tailored to project needs. Their skill in shape design tackles tough building challenges while keeping costs low. Check their technical skills and offerings through XiHui Aluminium’s corporate overview.

FAQs About Aluminum Extrusion

What types of aluminum alloys are commonly used in extrusion?

Common alloys include 6061, 6063, and 7075. The 6061 alloy is strong and rust-resistant. The 6063 alloy has a smooth surface for decorative uses. The 7075 alloy is very strong for aerospace. Each is chosen based on the task’s needs.

How does aluminum extrusion differ from other metal shaping processes?

Extrusion is unique. It pushes heated aluminum through a die. This creates continuous profiles with exact shapes. Unlike casting or forging, it allows complex forms. It also offers high efficiency.

Can customized designs be achieved through aluminum extrusion?

Yes, aluminum extrusion is great for custom profiles. Precise die design allows tailored shapes. Suppliers like XiHui Aluminium create profiles for specific uses, like window frames or industrial parts.

Light but Tough: Aluminum is one-third the weight of steel. Still, it holds strong structural power.