Aluminum profiles are extruded parts that act as key structural and functional pieces in many engineering uses. Their growing popularity comes from a special mix of features: low weight, strong strength-to-weight balance, rust resistance, and shape adaptability. These qualities make aluminum profiles a top pick in fields like aerospace, automotive, building, and electronics.

Adding aluminum profiles to structural setups boosts modularity and eco-friendliness. In particular, during prototyping and large-scale production, their flexibility allows for budget-friendly design changes and expandable making processes. XiHui Aluminum provides exact custom CNC machined aluminum profiles made for high-performance areas. This ensures the main support of today’s engineering is both dependable and effective.

Technical Characteristics of Aluminum Profiles

Aluminum’s strong strength-to-weight balance improves load support while greatly cutting overall system weight. This matters a lot in areas like automotive and aerospace. There, weight savings directly boost how well things work.

Our ISO 9001-approved methods guarantee tough, light parts with better rust resistance and heat flow. These are vital for lasting in tough settings and handling heat spread in electric and mechanical setups.

Common Alloy Grades and Their Engineering Uses

The most often used alloys include:

6061: Famous for its great mechanical traits and joining ease, it fits general structural jobs.

6063: Preferred in building designs because of its fine surface look.

7075: An aerospace-level alloy with outstanding strength, it goes into plane bodies and top-speed vehicle parts.

XiHui uses aerospace-level alloys (6061, 7075) to match strict needs in areas like automation, automotive, and green energy setups.

Structural Functions Across Engineering Disciplines

Aluminum profiles help build machine frames, flexible covers, and gear bases. Industrial aluminum profiles are light, good-looking, and simple to put together or take apart. Their shape—usually square or rectangular with inside slots—backs T-slot joining systems. These skip the need for welding or special fixing tools.

Integration into Dynamic Mechanical Assemblies

In automation and robot systems, aluminum profiles work well for holding moving parts like straight guides and movers. With cutting accuracy up to ±0.01mm, they keep size steady. This is key for holding proper position over time under moving loads.

Applications in Architectural Engineering

Aluminum profiles allow making of wall covers, shade screens, window frames, and fronts with little waste. Architectural profiles mainly serve aluminum alloy sliding windows, aluminum alloy sliding doors, aluminum alloy swing doors, aluminum alloy swing windows, and glass curtain walls. The material’s bendability lets builders try out tricky shapes. At the same time, it keeps solid strength.

Customization Potential Through CNC Machining Technology

XiHui Aluminium uses multi-axis CNC tools for fast cutting, drilling, milling, and threading work. Better CNC cutting (±0.01mm accuracy) permits very exact part addition. It also makes sure fit with other mechanical pieces.

From Concept to Product: Realizing Creative Designs with XiHui Aluminium’s Custom Services

XiHui Aluminium focuses on full services—from quick model making to finish work—backed by inner design teams. By using CAD/CAM linking, the firm turns buyer plans into buildable answers. Size: Molded according to customer’s drawings; Color: Customizable anodizing, painting, wood grain and various colors. This means creators can make special section shapes through custom extrusion tools. Then, CNC after-work follows.

Surface Treatment Options for Enhanced Performance and Aesthetics

Surface treatments not only boost visual charm but also raise toughness. Surface treatment options include anodized, powder coated, sand blasted, polishing, and mill finish. Anodizing forms a rust-proof oxide coat and lets color choices. Meanwhile, powder coating gives high shield against wear and weather harm.

Surface Finishes for Specialized Applications

Clear anodizing provides electric isolation while keeping heat work. This makes it perfect for electronic shells and LED heat sinks.

Architectural Elements

Wood grain transfer films copy natural looks like oak or walnut. They do this without losing aluminum’s mechanical perks. Various colors such as wood grain; MOQ: Painting and wood grain = 2 tons. This makes these finishes open even for mid-size jobs.

Sustainability Contributions of Aluminum Profiles in Engineering Projects

Aluminum’s ability to recycle cuts lifecycle pollution a lot. Its light build lowers energy use in shipping during supply steps. Thus, it becomes a green choice for worldwide chains.

Role in Green Building Certifications (LEED/BREEAM)

Aluminum profiles with lots of reused content add points to LEED or BREEAM ratings. Heat-broken aluminum systems improve building shell work. They do this by cutting heat links.

XiHui Aluminium: Precision Manufacturing Partner for Custom Aluminum Profiles

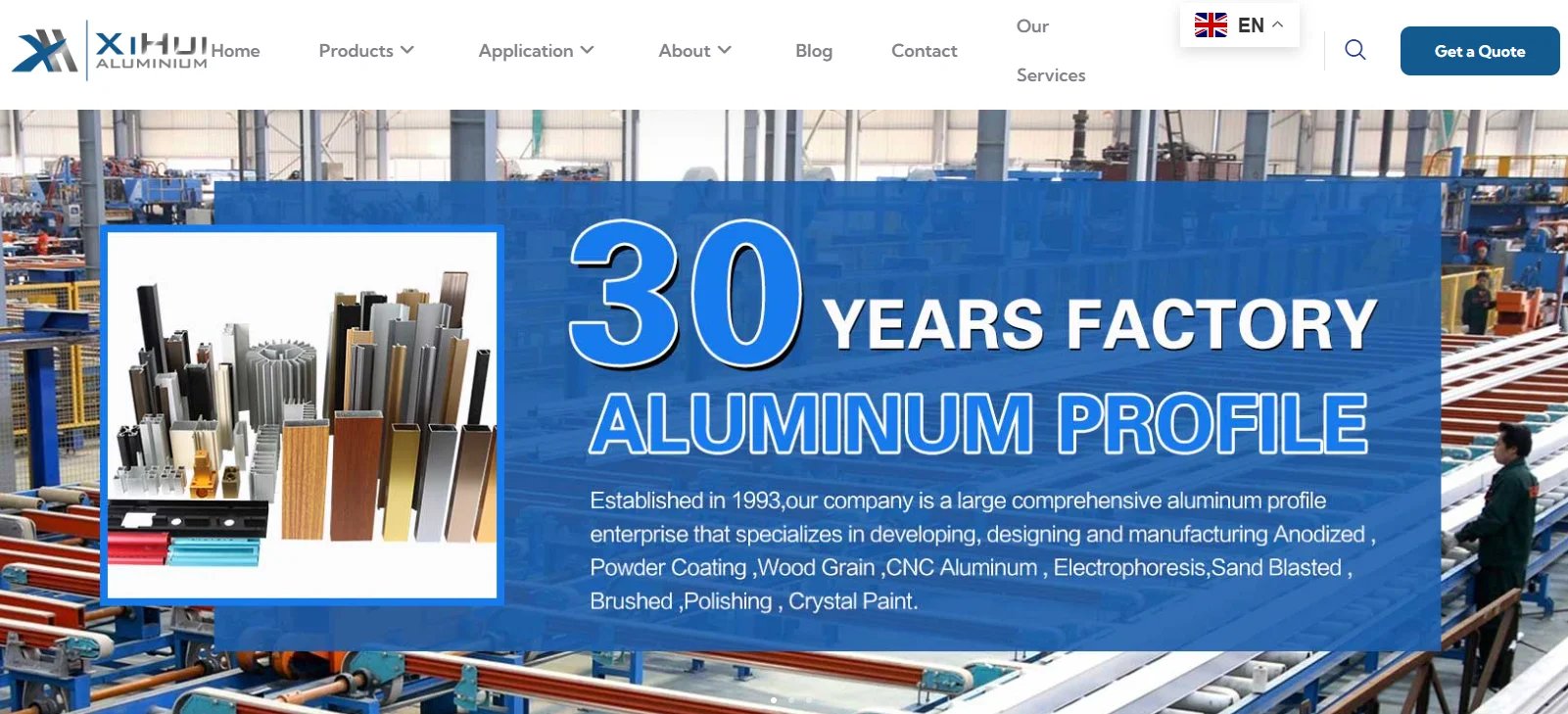

XiHui Aluminium Co. Ltd focuses on aluminum extrusion profiles. It excels at making very thin profiles. With 15 extrusion lines, 2 anodizing lines, 2 powder coating lines, and 40 CNC deep processing lines, the firm can offer very tailored fixes. Our plant could reach an output of 20000 tons annually.

Our group has committed setup engineers. They can give setup plans and joining ideas based on buyer needs. The firm’s team-work style covers from profile talks to end delivery. It helps fields like solar panel mounts, automation gear frames, and health tool shells.

Summary of Key Insights on Structural Roles of Aluminum Profiles

Aluminum profiles give flexible structural fixes over many fields—from exact automation builds to building frames. This works because of their modularity and material savings.

Enabling Innovation Through Customization

By mixing extrusion tech with exact CNC cutting, builders can make light but strong setups. These fit for use and looks without hurting making ease.

XiHui Aluminium Benefits from Preferential Anti-Dumping Duty Rate in Israel

According to relevant trade measures, XiHui Aluminium has been included in Israel’s “white list” for anti-dumping investigations concerning aluminium products. As a result, the company is subject to a significantly lower preferential duty rate of 37%.

In contrast, other Chinese aluminium exporters not listed on this white list face a substantially higher anti-dumping duty of 110%. This stark difference highlights the critical advantage gained by XiHui Aluminium through its compliance and successful response to the investigation, allowing it to maintain relative price competitiveness in the Israeli market.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC-machined aluminum profiles?

The MOQ usually begins at 100 meters per profile design. But it can change with difficulty and needed surface work. XiHui Aluminium gives bendy batch sizes for model projects.

Q2: What surface treatment options are available for CNC-machined aluminum profiles?

Usual choices cover anodizing (clear or colored), powder coating (matte/glossy), electrophoresis coating, sandblasting, polishing, brushing, and wood grain transfer printing. These fit based on use needs.

Q3: Does XiHui Aluminium support structured data markup (Schema) on product pages?

Yes. The company adds schema.org structured data to its online product lists. This raises search engine views through rich bits. These include specs, stock status, price ranges, etc.