As choices for metal blends change in precise cutting, folks search for reliable picks. In 2026, options will stress tough types. Issues crop up from thermal stress and strict tolerances. However, skilled people manage them. They rely on proven suppliers. One prominent player is XiHui Aluminium. This team produces profiles that satisfy diverse requirements. Their products provide durability and savings. Groups depend on them for excellent results in large projects.

Trends in CNC Milling and Material Demands Toward 2026

Evolving Requirements in High-Precision CNC Applications

As you get ready for the coming years in CNC milling services, the field is moving to stricter rules in main areas. Sectors like aerospace, automotive, and consumer electronics lead this change. They need parts with very close tolerances. This push for accuracy goes beyond just size precision. It also involves steady results in production runs, particularly for vital tasks.

Another big need is for materials that mix light weight with solid build strength. Light alloys with good strength-to-weight balances turn essential for better fuel use in vehicles and easy carrying in gadgets. Surface quality counts a lot too. Parts must fit exactly. They also need good-looking and useful outer layers, like rust-proof anodized coatings.

These changing needs show that picking materials for CNC milling has to match both cutting ease and end part work. This is why aluminum alloys, mainly 6061 and 6063, stand out as key choices.

The Role of Aluminum Alloys in Precision Machining

Aluminum stays a main pick for exact CNC milling because of its built-in benefits. It cuts well, handles heat nicely, and weighs little. So, it fits quick test builds and large-scale making.

Some aluminum alloys differ from others due to their mix of power, shaping ease, and outer look. For picking an alloy for CNC-milled items that need outer treatments like anodizing, you must choose a fitting type.

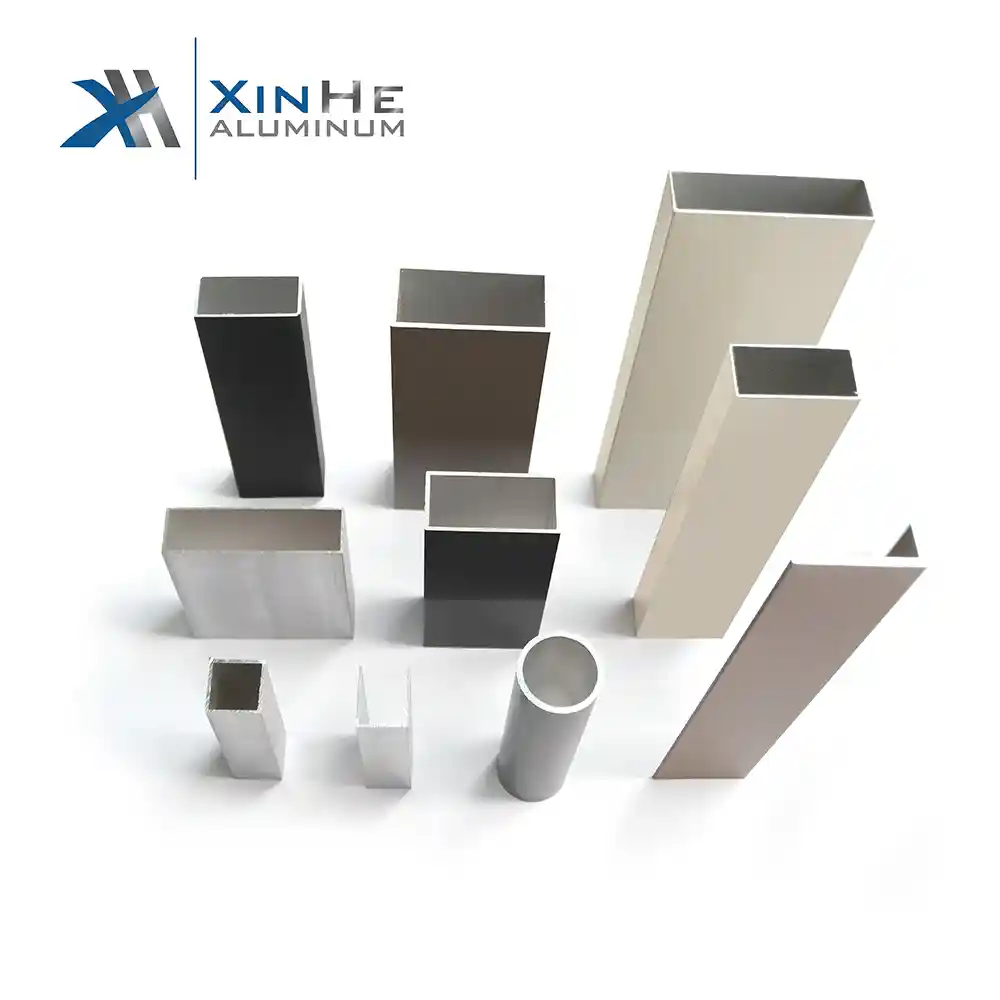

Aluminum alloy 6061 and 6063 T5 act as common factory aluminum shapes. They work as base stuff in uses like frame outlines, tool supports, and cover boxes. Their fit for both build and look-based jobs makes them great for made-to-order pushed shapes suited for CNC milling tasks.

Key Criteria for Selecting Aluminum Alloys for CNC Milling

Mechanical Properties and Dimensional Stability

When checking materials for your CNC milling work, build strength comes first in your thoughts. Alloys need to keep their form under cutting push, above all in fast milling. Pull strength and bend strength affect how well an alloy keeps close limits during cutting.

Shape steadiness matters just as much. Heat spread in tool work can cause tiny shape changes. Alloys that hold their form in warmth and push give better repeat results. They also cut down on fix-up work.

Surface Finish Quality and Anodizing Compatibility

A smooth CNC process cuts down on after-work steps. Aluminum alloys that give even outsides in milling lower sanding or shine needs. This saves hours. It also boosts eye appeal, which is key for user-seen or build parts.

Plus, if the end item needs anodizing for rust block or look value, pick an alloy that works well with it. For example, 6063 gives top marks when anodized. This comes from its even surface and tight grain setup.

Machinability and Tool Wear Considerations

Tool wear hides costs in CNC jobs. Picking aluminum alloys with good chip build and less scratch on cut tools boosts work flow.

Alloys like 6061 get picked not just for power. They also help with clear chip removal and less cut push. So, tools last longer. Changes happen less often. Quality stays even.

Comparison of Popular Aluminum Alloys for CNC Milling Applications

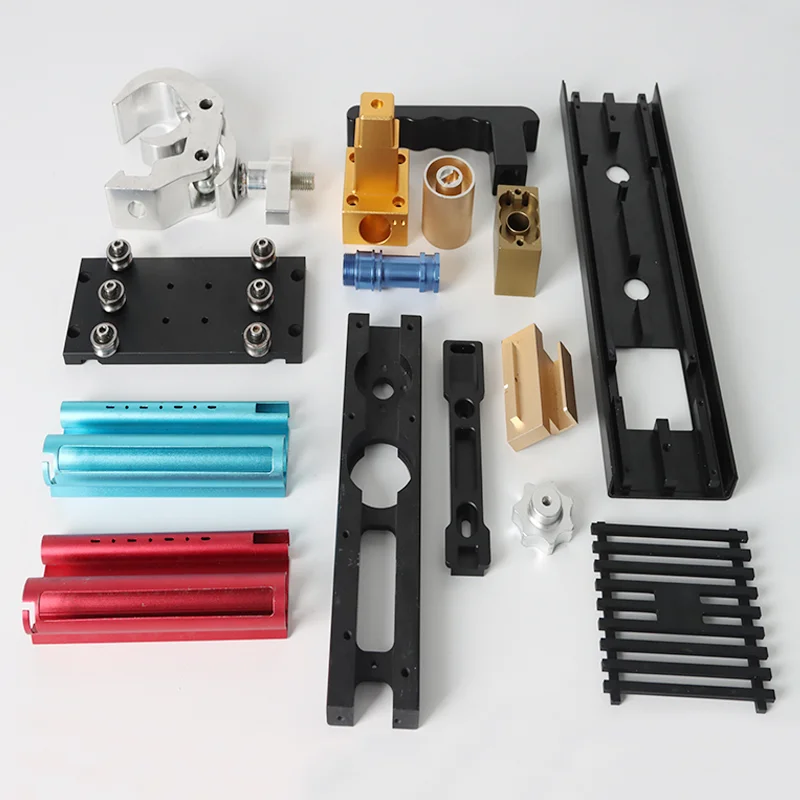

| Service | CNC Machining, CNC Milling and Turning, Laser Cutting,Drilling, Grinding, Bending, Stamping, Welding and so on. |

| Material | Aluminum:A2017/A2024/A5052/A5056/A6005/A6060/A6061/A6063/A6082/A6463/A7075/ADC12/AC4C T5/T6 |

| Precision | +/-0.005 ~ +/-0.002mm |

| Surface treatment: | Anodized,powder coated,sand blasted, polishing,mill finish,etc |

| Shape | Square, Rectangle, Round, Flat, Angle, T profile etc. |

| Drawing format | JPEG,PDF,AI,PSD,DWG,DXF,IGS,STEP; |

| Application | Automated machinery and equipment, electronic machinery industry, production lines, assembly line workbench, screens, industrial fences and various frames, display stands, shelves, mechanical dust seals, etc. |

| Characteristics | Strong, stylish, durable, corrosion-resistant. |

| Packing Details | Inside : packed with plastic film to protect each piece. Outside: Wrap to be bundles by waterproof craft paper or EPE film. Customized as customers request is available. |

Overview of 6061 Alloy Characteristics

6061 ranks as one of the most flexible aluminum alloys out there. It blends strong build power and rust block, mainly after anodizing. This suits build parts that need exact work.

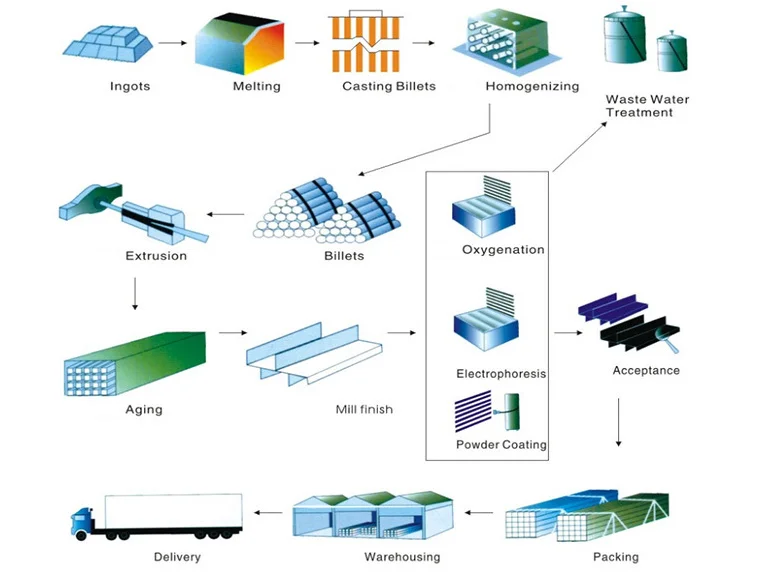

Aluminum Industrial Profile,Industrial aluminum extruded profiles, also known as industrial aluminum alloy sections, are alloy materials primarily composed of aluminum. These profiles are manufactured by heating aluminum billets to a molten state and extruding them into specific cross-sectional shapes. The mechanical properties and applications of these profiles vary significantly depending on the proportions of alloying elements added during production.

You will see this alloy in plane supports, car parts, and machine holds where power must not fail.

Overview of 6063 Alloy Characteristics

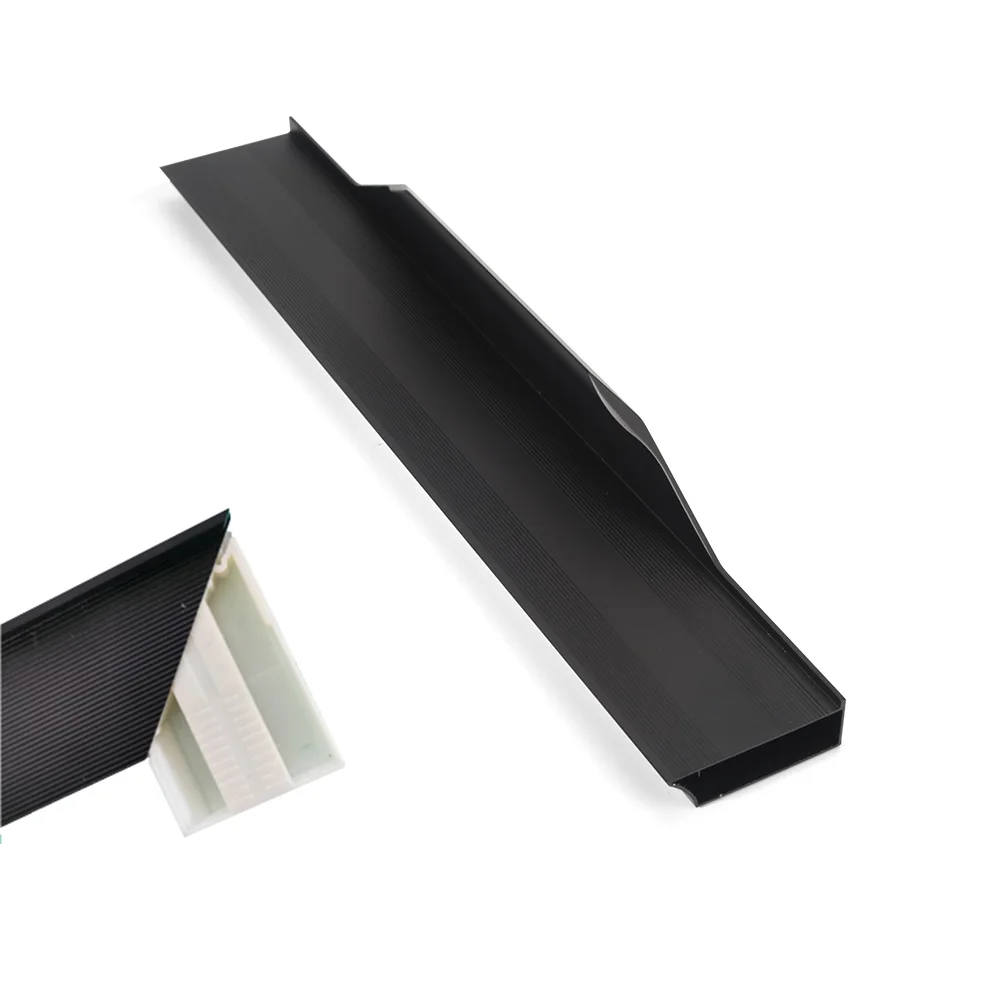

On the other hand, 6063 shines in jobs where looks match work as equals. It has better outer finish traits. So, it fits parts seen in user goods or build setups.

It lacks the power of 6061. Yet, it makes up with easier push and shape work. This lets you cut it into tricky forms. It still gives fine anodized outcomes.

T5 Temper Treatment: Performance Enhancement Explained

The T5 temper mark boosts aluminum’s work in cutting a lot. T5 temper means steady cool from push, then man-made age. This raises hard level. It keeps shape steady in added cutting steps.

So, parts from T5 set shapes suit close-limit milling without bend or twist. This holds true in fields like exact tools or plane build.

XiHui Aluminium’s Custom Extruded Solutions for CNC Milling Needs

If you look for a team to give steady top-grade pushes set for exact cutting, XiHui Aluminium mixes material know-how and make skills well. With over thirty years of work and thousands of push molds, they stand ready to hit your set needs.

Their made 6061 T5 shapes give the build toughness needed for plane-level parts. They keep high cut ease too. XiHui Aluminium promises even alloy mix and shape truth. Each run sticks to tight limit rules.

For outer-touch jobs like gadget covers or show build items, anodized 6063 T5 shapes from XiHui add better look traits. They bring use perks like rust block. At Xihui Aluminum, our state-of-the-art production facility, equipped with advanced anodizing and powder coating lines, ensures that each product not only meets but surpasses industry standards for durability, aesthetics, and performance. This setup means every item gets strong last, nice looks, and good work.

Their own push skills link full with CNC milling wants. This cuts wait times. It raises check control in every make step. XiHui Aluminium focuses on details that matter. They use top tools to keep things on track. As a result, clients get reliable parts every time.

How XiHui Aluminium Enhances Value Through CNC Milling Services

Turnkey CNC Milling Solutions from Profile to Finished Part

Time matters in today’s make cycles. XiHui Aluminium gives full-range help, from custom push to exact CNC milling. This one-stop way cuts hassle in linking many sellers.

Each part gets cut to your special plan specs. They use alloys like 6061 and 6063 T5. These fit your end job well. The process starts with raw shapes. Then, it moves to fine cuts. Finally, you get ready-to-use items. This flow saves effort and boosts speed.

Supporting Industries Requiring High Accuracy Components

Be it parts for plane builds, car frame systems, or gadget boxes, a sure aluminum push team that gets cutting fine points can shift results.

Aluminum alloy doors, windows, and curtain wall accessories—such as corner joints, door locks, hinges—benefit from precise dimensional control enabled by advanced CNC processing. The same applies to industrial automation frames or robotics platforms where tolerance deviation can compromise entire assemblies. These items need spot-on sizes. CNC work from XiHui Aluminium makes that happen. It helps in home builds, car setups, and tech frames. No matter the field, accuracy stays key.

Consultation & Technical Support Availability

You will not wonder alone when teaming with XiHui Aluminium. Their set engineer group gives plan fix help. This makes sure each push shape fits CNC cutting steps full.

This team way cuts later problems. It lifts end part work max. You can link right to XiHui’s tech group to talk alloy picks or send your CAD plans for price check. They guide you step by step. Questions get clear answers fast. This builds trust and smooth work flow.

FAQ

Q: What makes aluminum alloys like 6061 and 6063 ideal for CNC milling?

A: These alloys offer excellent machinability, good thermal stability during cutting operations, favorable chip formation characteristics, and compatibility with surface treatments like anodizing.

Q: Why is T5 temper preferred for CNC-milled aluminum parts?

A: T5 temper ensures higher hardness through artificial aging after extrusion cooling. This increases dimensional stability during high-precision machining.

Q: How does XiHui Aluminium ensure consistency across batches?

A: XiHui Aluminium applies strict quality control over alloy composition and profile dimensions through their integrated in-house extrusion and CNC facilities.