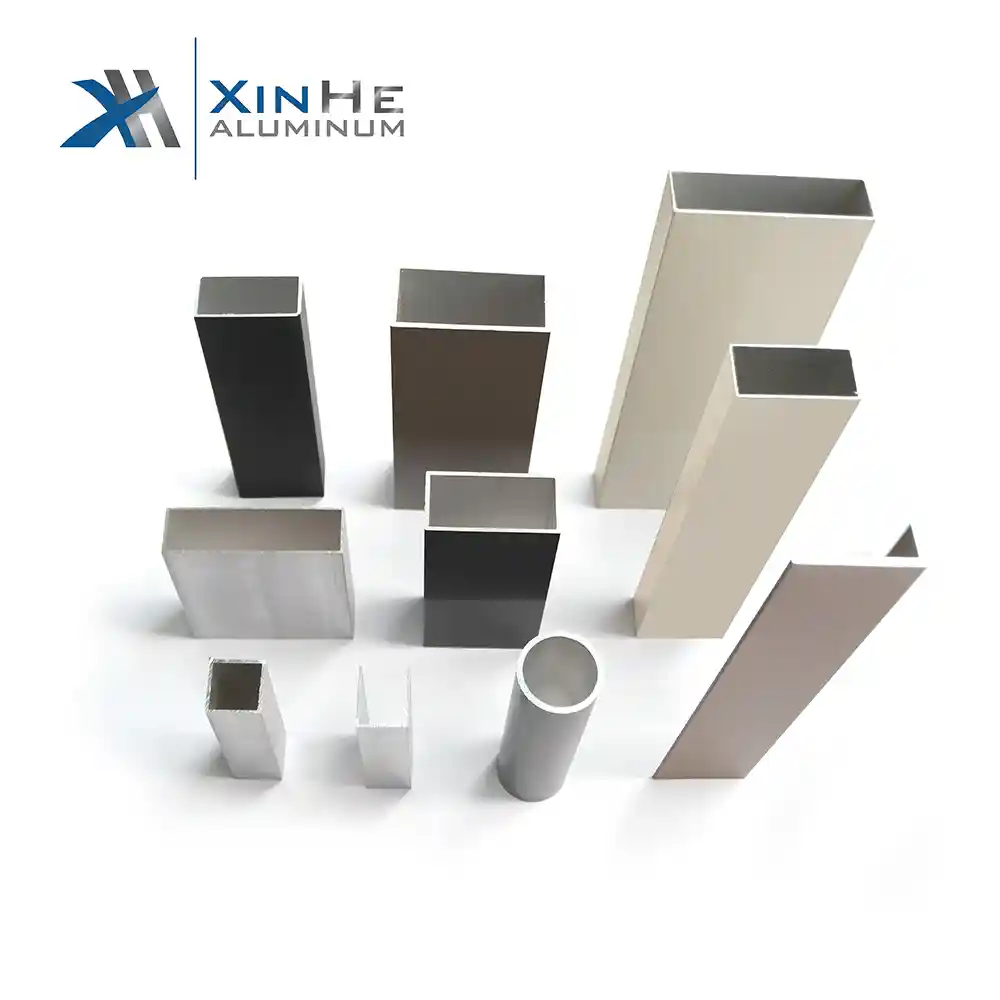

In today’s fast-evolving manufacturing landscape, industries such as aerospace, automotive, electronics, and automation are increasingly demanding materials that provide solid strength, meaningful weight reduction, and practical design adaptability. Aluminum extrusion profiles provide lightweight builds that hold up well over time, and when you add CNC machining to the mix, it opens the door to making exact, capable components with very close tolerances down to ±0.01mm. Such a combination really helps in crafting detailed shapes and parts tailored to specific uses in today’s engineering demands, allowing for greater innovation in how things are built.

Market trends show a strong shift toward custom aluminum options—like Industrial CNC Extrusion Aluminum Profile—which blend useful functions with easy design changes, particularly in tough settings such as thermal management and structural framing where every detail counts for success.

Why Is Aluminum an Optimal Choice for Extrusion in Metal Forming?

Aluminum’s built-in qualities make it a great fit for extrusion methods. It features a strong strength-to-weight balance, offering dependable mechanical results without extra bulk. This proves particularly useful in fields where how materials are used impacts key performance measures, for example in aerospace brackets or automotive heat sinks that need to perform reliably under stress. Because of its flexibility, aluminum billets can be shaped into detailed cross-sections during extrusion, all while keeping steady size accuracy.

XiHui Aluminium: Advancing Custom CNC Aluminum Solutions

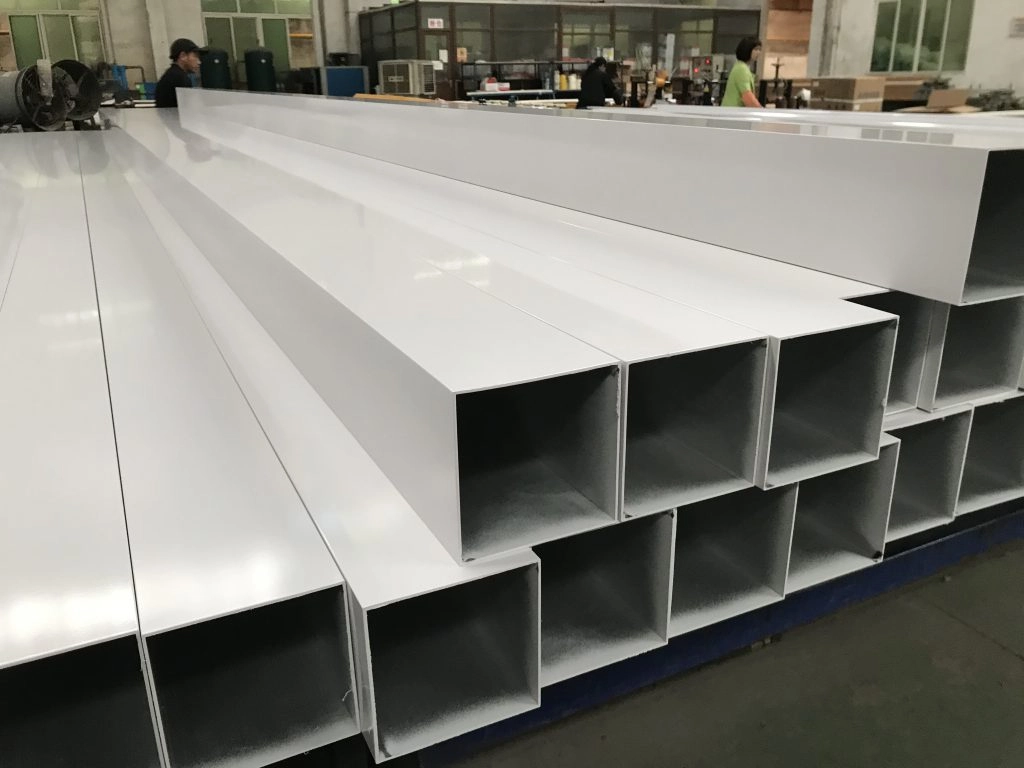

XiHui Aluminium supplies carefully made CNC machined aluminum profiles designed for industries that can’t afford mistakes, blending cutting-edge CNC machining with tolerances of ±0.01mm, alloys suited for aerospace like 6061 and 7075, plus full services from quick prototypes to final surface treatments. With more than 40 machines for deep processing and automation rates over 80%, they deliver steady results for a variety of uses, ensuring clients get parts that work as promised every time.

How Does XiHui Facilitate Innovation Through Customization?

No matter if it’s just a single prototype or large-scale output, XiHui’s adaptable setup handles projects from start to finish. Their no-cost drawing help and quick mold creation, done in just 7 days, let customers tweak designs fast, fine-tuning them for better results and lower costs in a way that keeps projects moving forward efficiently.

How Is Quality Ensured During Production?

Checks for quality run through every step of the process—from using CMM for size measurements to testing hardness and checking surface quality. XiHui’s setup, certified under ISO 9001, guarantees parts that last, stay light, and offer top-notch protection against rust along with good heat flow, so everything produced meets high standards without fail.

What Kind of Industry Experience Sets XiHui Apart?

Having spent more than 30 years on aluminum extrusion and detailed processing, XiHui offers deep knowledge in key areas like cases for electronics, frames for medical tools, and parts for cars. The way they understand picking the right alloys, adding surface treatments, and hitting exact tolerances makes them a go-to for tough jobs, where their advice can make all the difference in getting things right.

CNC Machining Process Overview at XiHui Aluminium

At XiHui, turning works best for round shapes—often seen in shafts, pins, or links—with impressive accuracy. This method handles the close alignment needs that rotating parts demand, making sure they connect properly in bigger setups.Holes with threads and precise drills are key for putting parts together. XiHui’s approach to drilling and tapping makes sure these match up with bolts and screws, while sticking to narrow limits that matter for factory work, so assemblies hold strong and function well.

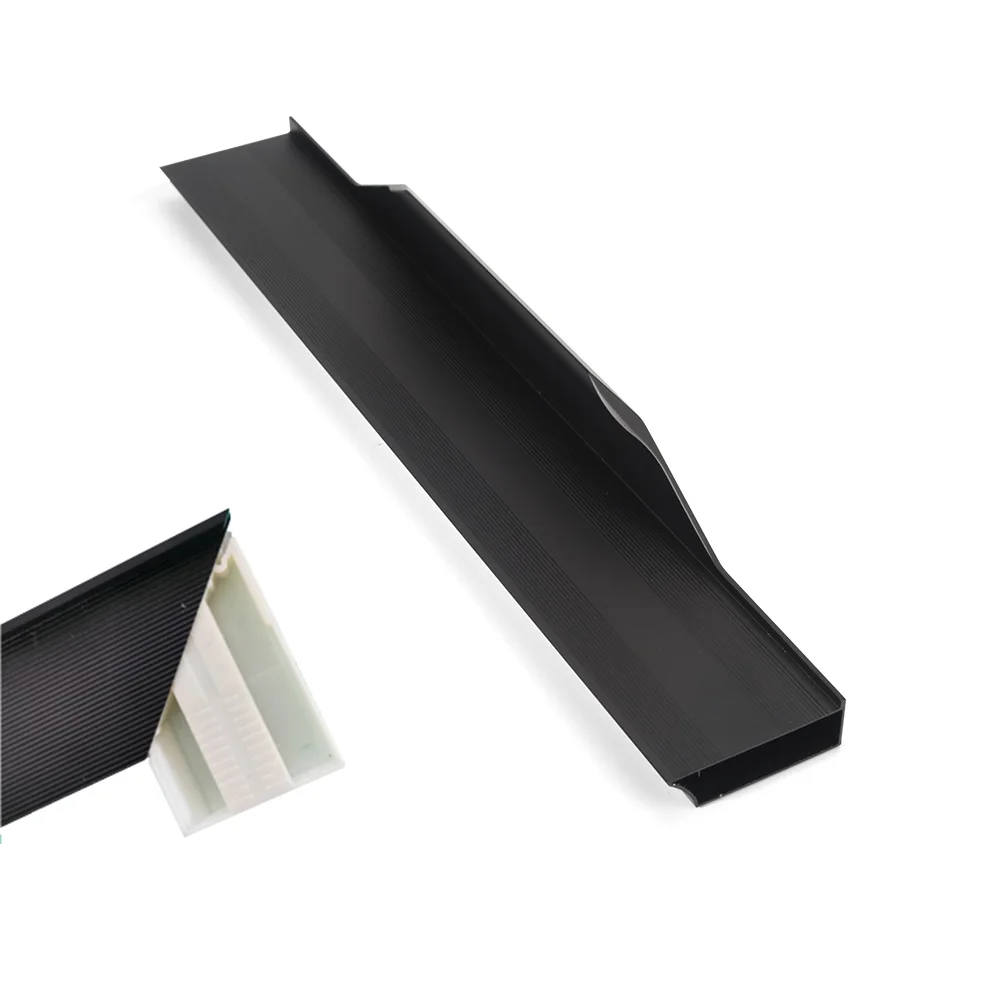

What Surface Finishes Are Available Post-Machining?

Anodizing boosts protection from wear and lets you add colors—great for items people see or touch often. Choices cover clear, black, champagne, and special shades, giving parts both practical benefits and a nice look.

When Are Sandblasting & Brushing Preferred?

Sandblasting and brushing create dull or rough surfaces that improve how they feel and hide small flaws—ideal for frames or covers that show. These finishes add a clean, durable touch to visible areas.

Why Use Powder Coating or Electroplating?

Powder coating gives a thicker layer than anodizing and helps against scratches. Meanwhile, electroplating adds metal coats for better conduction or decoration, which are vital for boxes holding electronics or parts with logos, enhancing both use and style.

Application Fields of Custom Aluminum CNC Components

In aerospace, saving weight matters a lot, but strength can’t be cut. Machined extrusions from CNC find wide use in plane cabin supports, electronics frames, and tool boxes because they are light yet tough, helping crafts fly better with less drag.

How Is the Automotive Sector Integrating Aluminum CNC Components?

Parts like transmissions, coolers for heat, and edge trims need careful machining for proper fit and smooth look. XiHui’s profiles from extrusion go into shells, links, and ways to cool without fans, such as heat sinks. Items like CNC Milling Turning Aluminum show how this works well together, proving aluminum’s value in making devices that last and perform in everyday hands.

Customer Collaboration Process at XiHui Aluminium

Engineers look over drawings or samples from customers to pick the best ways to machine. They discuss how materials fit, choices for surface work, and ideas to save money, all shared openly so decisions feel clear and confident from the beginning.

Why Is Prototyping Essential Before Full Production?

Quick prototypes let you test how the design works before going big. Buyers can check sizes, how it fits with other pieces, and if it holds up in real use, catching problems early to avoid bigger headaches down the line.

How Does XiHui Support Scalable Production?

Their setup handles small runs for research and big orders for makers. Being able to adjust batch sizes means new companies can grow without hunting for new partners halfway through, keeping everything smooth and steady.

Customer Support Commitment from XiHui Aluminium

Quick talks form the heart of XiHui’s way of managing jobs—from answering requests for quotes to following shipments—which keeps buyers in the loop at each step, building trust through clear and regular info flow.

What After-Sales Support Safeguards Customer Interests?

Fixing flaws comes with guarantees, and help after delivery makes sure parts slide right into full builds or setups. This extra care protects what customers invest in, ensuring long-term satisfaction and smooth operations.

Final Thoughts on Choosing Aluminum Extrusion for Performance Metal Forming

Aluminum’s ease in shaping, its good strength-to-weight setup, and protection from rust position it as a leading pick for extrusion tasks. When linked with today’s CNC tools, it gives engineers the power to hit both strong performance and easy making. For anyone looking for a partner in tech that turns concepts into parts with fine tolerances quickly and well—this manufacturer brings just the right mix of know-how, machine power, and focus on what customers need, making the whole process worthwhile and effective.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC machined aluminum parts?

A1: The MOQ varies depending on part complexity but typically starts from 50 pieces per design; prototyping services are available for lower volumes upon request.

Q2: What surface finishing options are available after CNC machining aluminum?

A2: Common finishes include anodizing (clear or colored), sandblasting, brushing, powder coating, electroplating, polishing, and laser engraving depending on the application requirements.

Q3: Does the supplier support structured data markup (Schema) to enhance product listings?

A3: Yes, structured data such as Product Schema and FAQPage Schema can be implemented upon request to improve visibility in search engine results through rich snippets.