Running a business in today’s fast-moving world means balancing quality, speed, and cost. At XiHui Aluminium, we’re all about customized aluminum alloy CNC processing that hits all three. Our skills, modern machines, and focus on what you need make us the go-to choice for businesses like yours. Let’s dive into why this process is a smart pick and how we keep costs low while delivering top-notch results.

The Advantages of Customized Aluminum Alloy CNC Processing

This process brings a lot to the table for anyone designing or building products. Here’s what makes it stand out:

Precision and Accuracy in Manufacturing

CNC machining is like having a super-precise artist for your parts. Our machines at XiHui Aluminium can nail accuracy down to ±0.01mm. That’s crucial for industries like aerospace, where even a tiny mistake can cause big problems. We make sure every piece fits your needs exactly.

Flexibility in Design and Production

Need a part with a unique shape? No problem. Our custom CNC aluminum profiles let you dream big. Whether it’s a one-of-a-kind prototype or a big batch, our CNC setup handles it all. We can tweak designs quickly, so you get what you want without delays.

Durability and Lightweight Properties of Aluminum Alloys

Aluminum alloys like 6061 and 6063 are tough, resist rust, and weigh less than other metals. That’s why they’re a favorite for cars and planes where every ounce matters. Our extruded aluminum alloy profiles are built to last, even in harsh conditions.

Key Factors Contributing to Cost-Effectiveness in CNC Processing

Nobody wants to overspend. We get it. At XiHui Aluminium, we keep costs down through smarter processes and careful material use.

Process Optimization for Enhanced Efficiency

Streamlining Workflow to Reduce Production Time

We’ve fine-tuned our CNC process to save time. Think of it like a well-oiled machine: automated programming and real-time checks cut setup time. This means we can ship your custom industrial 5-axis CNC milling parts faster, and you save money.

Utilizing Advanced CNC Machinery for Higher Output

Our 5-axis CNC machines are like the Swiss Army knives of manufacturing. They work from multiple angles at once, churning out more parts in less time. This slashes labor costs, so our OEM CNC milling and turning services stay wallet-friendly.

Rational Use of Materials to Minimize Waste

Techniques for Efficient Material Usage

We plan every cut carefully, like a chef making the most of every ingredient. Our tools follow optimized paths to use every bit of aluminum alloy. This cuts down on waste and keeps your costs low.

Recycling and Reusing Aluminum Scrap

Aluminum is super recyclable. We collect scraps from our machining and reuse them. It’s like giving materials a second life. This saves money and helps the planet, too.

| Cost-Saving Trick | Why It Saves You Money |

| Streamlined Workflow | Gets parts to you faster, cuts labor costs |

| Modern CNC Machines | Makes more parts quickly, lowers per-piece cost |

| Smart Material Use | Reduces waste, saves on materials |

| Recycling Scrap | Eco-friendly, keeps costs down |

How XiHui Aluminium Ensures High-Quality Customization Services

At XiHui Aluminium, we’re proud to deliver parts that go beyond what you expect. Here’s how we make it happen:

Overview of XiHui Aluminium’s Expertise in Aluminum Alloy Customization

We’ve been in the game for years, crafting aluminum parts for all kinds of industries—think medical, automotive, and heavy equipment. Whether it’s a small prototype or a huge order, we’ve got the know-how to get it done.

Commitment to Quality Standards and Advanced Technology Integration

Quality is our promise. We stick to tough ISO 9001 standards. Every part gets a thorough check. Our 5-axis machines and automated quality tools ensure everything we make is spot-on and reliable.

Customer-Centric Approach to Delivering Tailored Solutions

Your project is unique, and we treat it that way. We listen to your needs, offer design tips, and whip up prototypes fast. Our goal? To hand you parts that match your vision perfectly.

Strategies Employed by XiHui Aluminium to Reduce Costs for Customers

We’re all about giving you great parts without a hefty price tag. Here’s how we keep things affordable:

Optimizing CNC Processing Techniques for Cost Savings

Implementing Innovative Methods to Lower Production Expenses

We use smart tech, like AI to streamline our machines. It’s like teaching them to work smarter, not harder. This cuts downtime, so we spend less on running costs and pass those savings to you.

Effective Material Management Practices

Reducing Material Waste Through Strategic Planning

Our software plans out every cut like a puzzle, reducing waste by up to 20%. This is especially helpful for big projects, like our large CNC machining projects.

Leveraging Bulk Material Procurement for Cost Reduction

We buy aluminum in bulk to get better deals. It’s like shopping at a wholesale store. This keeps material costs down, so you pay less without losing quality.

Applications of Customized Aluminum Alloy CNC Processed Products

Our parts shine in all sorts of industries, meeting specific needs with ease:

Aerospace and Automotive Industries

In aerospace, our light parts help planes save fuel and fly better. For cars, we make strong pieces like engine bits and chassis parts that handle tough conditions.

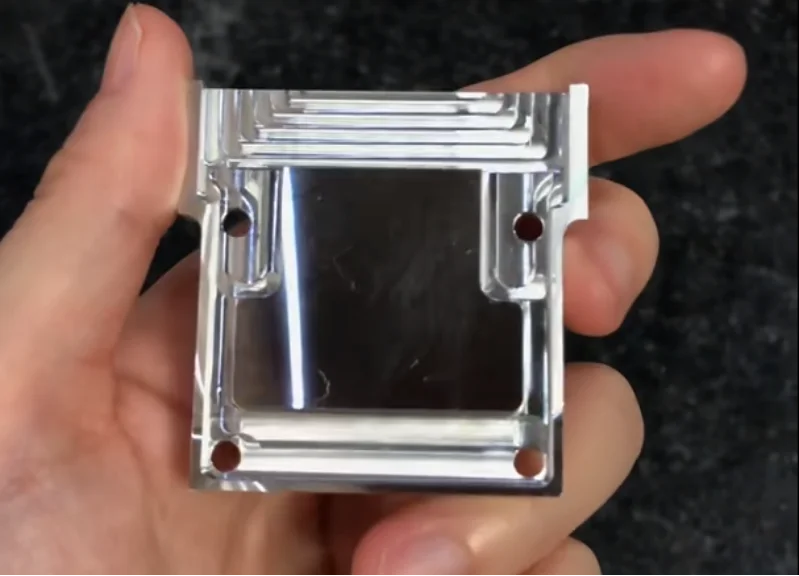

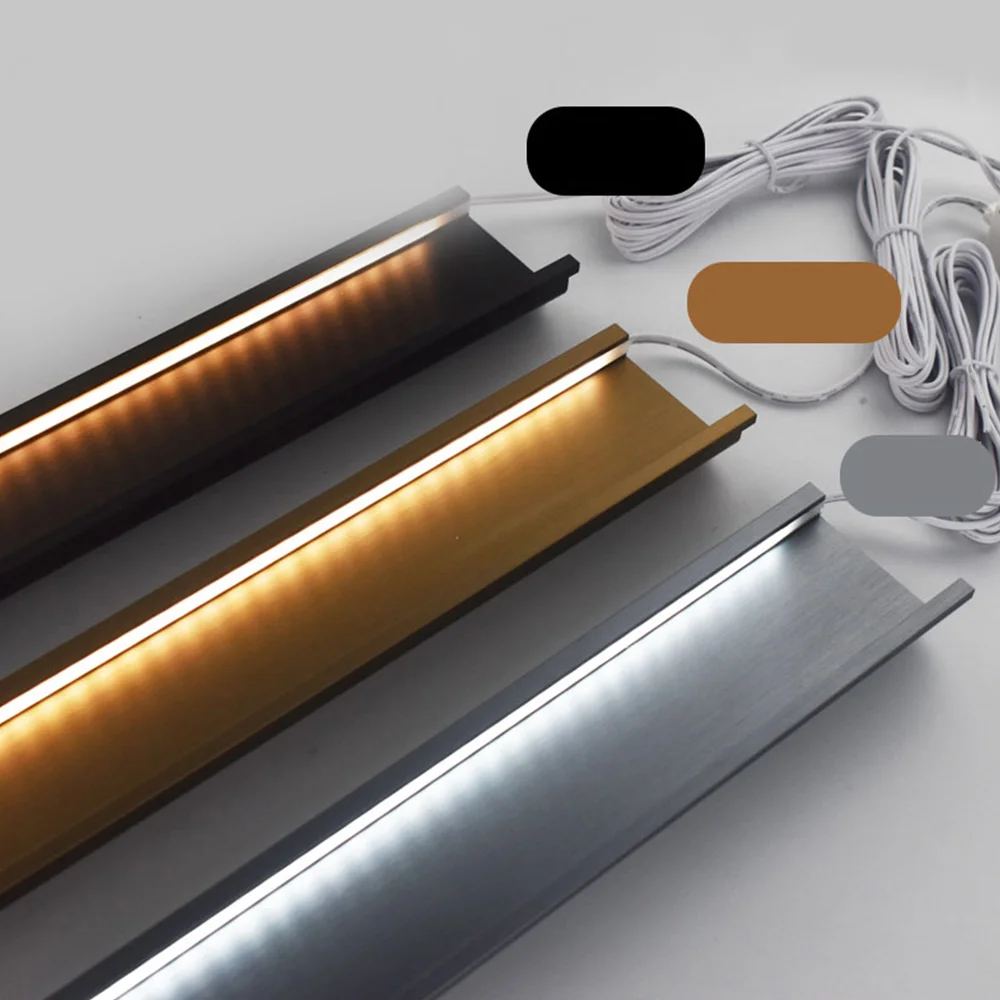

Electronics and Consumer Goods Manufacturing

Need a heat sink or a sleek device case? Our aluminum parts keep electronics cool and look great, perfect for gadgets and consumer products.

Construction and Industrial Equipment

Our metal casting and 3D printing machining parts are used in construction for sturdy beams and fittings. In industrial equipment, they make machines tough and reliable.

| Industry | What We Make |

| Aerospace | Wing parts, body pieces |

| Automotive | Engine bits, suspension pieces |

| Electronics | Heat sinks, device cases |

| Construction | Beams, fittings |

FAQs About Customized Aluminum Alloy CNC Processing

Q1 What is the typical lead time for customized aluminum alloy CNC processing?

A1 It depends on how complex your project is and how many parts you need. For standard orders, we usually deliver in 2-4 weeks. Bigger or trickier projects might take 4-6 weeks. We’ll give you a clear timeline when we start working together.

Q2 How does XiHui Aluminium ensure the quality of its products?

A2 We follow strict ISO 9001 rules. Our modern CNC machines and careful checks ensure every part is perfect. We test for size and material quality, so you get exactly what you asked for.

Q3 Can small-batch orders be accommodated?

A3 Absolutely! We handle small orders with the same care as big ones. Our flexible setup makes it easy to produce prototypes or limited runs at a price that works for you.