Industries are always finding new ways to create cool stuff, and the need for custom aluminum parts made with CNC tech has shot up. Whether you’re crafting one test piece or churning out thousands, folks in all sorts of fields want parts that are spot-on and can adapt to their needs. CNC (Computer Numerical Control) tech is a big help here. It lets makers build detailed aluminum pieces with awesome accuracy.

CNC machining lets engineers and designers whip up tricky shapes and hit tight targets. Those shapes would be super hard or just not doable with old-school methods. Plus, CNC is flexible. You can tweak designs fast, so every piece fits its job just right.

Making aluminum parts to match one-of-a-kind designs isn’t a hassle anymore—it’s a fun opportunity. From really thin bits to parts that do multiple things, custom CNC machining brings your ideas to life. It’s quick and won’t cost you an arm and a leg.

The Fundamentals of CNC Custom Aluminum Machining

CNC machining is a way to carve out material using tools run by computer programs. When you use it with aluminum, it takes advantage of how easy the metal is to shape. You can work fast without messing up the size or look.

Aluminum’s a go-to choice for CNC jobs because it’s got some neat features:

- Light Yet Tough: Aluminum’s strong but doesn’t weigh much. That’s great for parts where you need strength but want to keep things light.

- Awesome Heat and Electric Flow: Aluminum’s good at passing heat and electricity. That makes it perfect for stuff like electronic cases or parts that handle heat in fancy gadgets.

- Fights Rust and Looks Nice: Aluminum naturally holds up against rust. You can also add coatings like anodizing or powder coating to make it stronger and prettier.

From Concept to Creation: The Process of Custom CNC Aluminum Machining

It all starts with a digital plan. Engineers use CAD (Computer-Aided Design) software to turn ideas into clear 3D models. Those models get turned into directions for CNC machines using CAM (Computer-Aided Manufacturing) software. These tell the machines how to cut, drill, or shape the aluminum.

Prototyping’s a big deal. It lets you test how a part looks, fits, and works before making tons of them. This catches oopsies early, saving time and cash. That way, the design’s just what you need.

When it’s time to make lots of parts, a few steps happen. These include milling, drilling, turning, and adding final touches. Every step’s checked carefully to make sure each part’s the right size and meets quality rules.

Innovations in Customization Through CNC Technology

Today’s CNC machines are packed with cool ways to make parts your own:

- Multi-Axis Machining: These machines move tools in all sorts of directions at once. That lets you make fancy shapes with fewer steps and better speed.

- Automation: Automation cuts down on hands-on work. It keeps parts consistent and super accurate, which is awesome for big orders or parts that need exact sizes.

- Crazy-Precise Control: In fields like aerospace or electronics, tiny mistakes can mess things up big time. Advanced CNC setups make parts exact, down to super-small measurements, every single time.

Surface Treatment Options for CNC Machined Aluminum Parts

Finishing aluminum parts doesn’t just make ‘em look nice—it also makes them work better. Finishes protect against wear and rust:

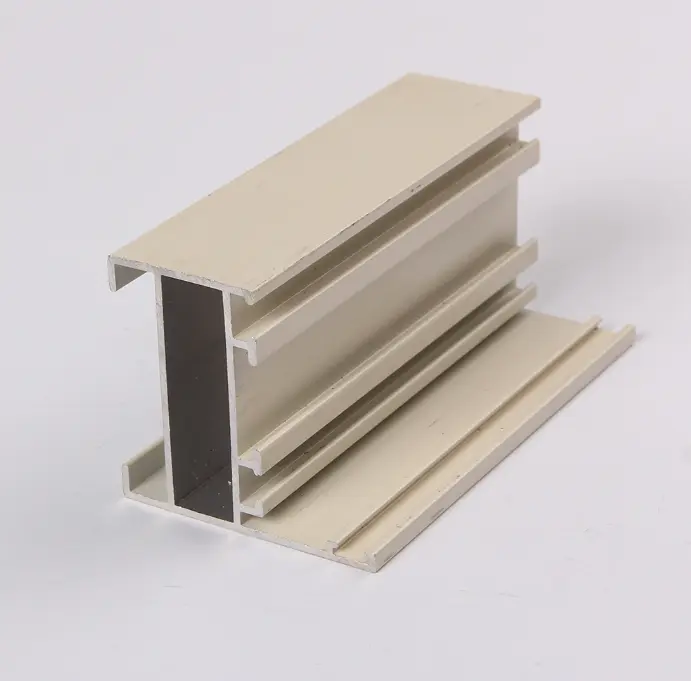

- Anodizing for Toughness and Style: This uses electricity to harden the surface. You can also add colors like silver or champagne to make it look cool.

- Powder Coating for Color and Strength: You can add colors like black or white with powder coating. It creates a tough layer that doesn’t chip or fade easily.

- Brushing, Polishing, and Sandblasting: These give different vibes, from shiny, smooth surfaces to rough, matte ones, depending on what you’re going for.

Industries Benefiting from Custom CNC Aluminum Parts

Custom aluminum parts from CNC machining pop up in tons of places:

- In cars, they’re used for engine bits, brackets, trims, and accessories. These need to be strong but not heavy.

- Aerospace needs precise aluminum pieces and cases. They’ve gotta handle rough conditions while staying light.

- Electronics use aluminum for sleek, sturdy cases. These mix style and function perfectly.

- In buildings, aluminum’s used for decorative trims or supports. These are made to fit unique designs.

XiHui Aluminium: Your Partner in Custom CNC Aluminum Solutions

With over 30 years of know-how in aluminum work, XiHui Aluminium’s a leader in custom CNC machining. Our top-notch setup has 15 extrusion lines and 40 machines for deep processing. That means we can handle everything from raw aluminum to finished parts without a hitch.

We make over 20,000 tons of aluminum parts yearly. Our OEM/ODM services reach more than 120 countries. Big or small, your project’s doable. Our skilled crew uses high-tech tools to turn your sketches or samples into real-deal products.

One-Stop Service from Concept to Delivery

We’ve got you covered from start to finish. Our team helps with research, mold-making, extrusion, and finishes like anodizing or powder coating. We check quality at every step. Depending on the job, we can deliver in 7 to 15 days. Our smart system keeps prices fair without skimping on quality.

Realizing Creative Ideas Through XiHui’s Customized Solutions

We team up with clients every step of the way, from early test pieces to big production runs. Our crew gives tips on making designs easier to produce. That helps you nail your idea before spending on tools.

Need slim pieces for modern furniture or tricky shapes for aerospace? Our huge mold collection and flexible options can tackle almost any challenge. Our engineers also help figure out how parts fit together in their final spot. We can even supply matching accessories based on your designs.

FAQs

Q1: What’s the minimum order quantity (MOQ) for custom aluminum CNC machining?

A: Usually, it’s 500kg per model. That makes our services doable for medium projects. You won’t have to order more than you need.

Q2: What surface treatment options are available for aluminum parts after CNC machining?

A: We’ve got anodizing (silver or champagne), powder coating (black or white), brushing, polishing, and sandblasting. These add strength and style for all kinds of industries.

Q3: Can you help with eco-friendly aluminum machining options?

A: Yup! We use green practices, like recycling aluminum scraps. Our methods cut waste and save energy. That way, your parts are good for the planet and meet your needs.