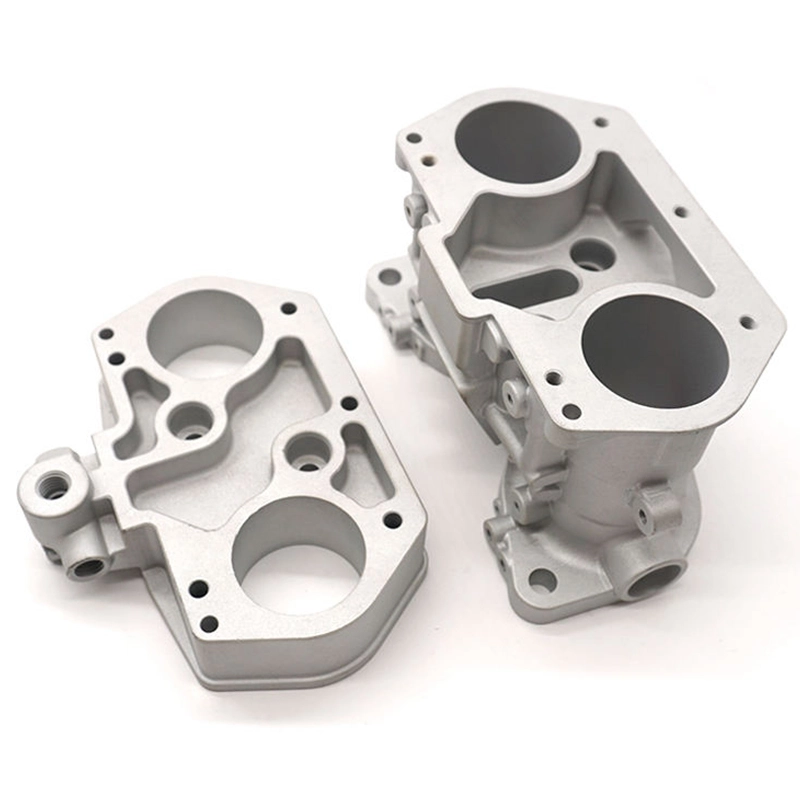

In today’s busy manufacturing world, being super accurate isn’t just nice—it’s what makes you the best. Getting really tight tolerances in CNC precision machining is super important for industries that need top-notch precision and reliability. Think airplanes, cars, electronics, or medical tools—high-precision aluminum parts are a must for great performance, safety, and dependability. These jobs often need parts with tolerances as tight as ±0.01mm, which is a big challenge. It takes careful work at every step to get it right.

This article dives into how we hit those super tight ±0.01mm tolerances when machining aluminum parts.

Key Factors Contributing to High-Precision CNC Machining

To nail a ±0.01mm tolerance every single time, manufacturers have to keep a close eye on lots of things that affect size and machining accuracy.

1. Environmental Control in the Workshop

Keeping the work area steady is a big deal for super precise machining.

- Keeping Temperature and Humidity Steady

Aluminum can grow or shrink when the temperature changes. Even a tiny 1°C difference can mess up sizes enough to miss the mark. That’s why top workshops keep the temperature super steady, within ±1°C. They also keep humidity low, under 50%, so the material doesn’t act up.

- Stopping Vibrations and Leveling Floors

Vibrations from other machines or bumpy floors can throw off accuracy. We use special pads to block shakes. Plus, we make sure floors are super flat to keep CNC machines steady. This helps tools move smoothly and avoids tiny wobbles while cutting.

2. Machine Selection and Maintenance

Awesome machines are the backbone of precise work.

- Picking Machines That Stay Consistent

We need machines that can repeat moves within super small margins, like ±2μm. These machines have cool features like linear scales and heat controls. They’re built tough to avoid bending when they’re working hard.

- Checking and Fixing Machines Regularly

We check machines often to keep everything lined up perfectly. We also do regular upkeep, like looking at spindles, checking oil systems, and fixing wear. This keeps quality steady for a long time.

3. Tooling and Cutting Strategies for Aluminum Precision

Picking the right tools and cutting plans is huge for keeping errors tiny.

- Why Sharp, Steady Tools Are a Must

Worn-out tools make too much heat and shake, which can mess up sizes. We use carbide tools with smooth edges or special coatings (like DLC) to cut aluminum smoothly. These tools stay sharp longer, even on big jobs.

- Keeping Tool Holders Steady

If tool holders aren’t balanced, they wobble. That hurts the surface and size accuracy. We balance them carefully so they spin evenly, especially at high speeds like 10,000 RPM or more.

- Best Ways to Cut Aluminum

We often cut in two steps. First, a rough cut takes out most of the material. Then, a finishing cut uses fast spins (12,000–20,000 RPM), slow feeds (0.05–0.15 mm/tooth), and shallow cuts (≤0.5mm). These tricks keep tools steady and make surfaces super smooth, which is key for ±0.01mm tolerances.

4. Material Quality and Its Impact on Precision

The stuff we use affects how well we can machine and how accurate parts turn out.

- Picking the Best Aluminum Type

There are lots of aluminum types, but we often use 6061-T6 or 7075-T6 for precision. 6061-T6 is great because it’s strong, can be welded, and doesn’t rust easily. It’s good for tons of projects. For tougher stuff, like airplane parts, we use 7075-T6. It’s stronger but trickier to machine.

- Sticking with Reliable Suppliers

We work with trusted suppliers to get the same material every time. This keeps machining consistent, which is super important when making lots of parts with strict size rules.

5. Programming and Software Optimization

Even awesome machines need smart plans to hit tiny precision levels.

- How CAM Software Makes a Difference

Computer-Aided Manufacturing (CAM) software lets us test tool paths before we start cutting. This cuts out guesswork. Tricks like climb milling ease up on tools, and trochoidal milling spreads heat evenly. Both help keep sizes spot-on.

- Testing Before We Cut

We run simulations to catch problems like crashes or extra cuts early. This saves materials and makes sure every part matches the design perfectly.

6. In-Process Inspection and Quality Assurance Measures

Checking work as we go is critical when we’re aiming for ±0.01mm.

- Probes for Instant Checks

We use probes on CNC spindles to measure sizes during cuts. If something’s off, the machine tweaks the tools right away.

- Checking Sizes with CMMs and Gauges

After machining, we use Coordinate Measuring Machines (CMMs) to check parts. They use touch or light sensors with crazy-good accuracy to make sure sizes are right. This ensures every part is perfect before it leaves.

- Lots of Quality Checks

We do quality control in layers. First, we check the first part (First-Article Inspection). Then, we track trends (Statistical Process Control). We also test batches and keep detailed records so customers know everything’s top-notch.

7. Skilled Workforce and Operational Expertise

Fancy tech isn’t enough—our people make it all work.

- Training Our Team

We keep training our workers on the latest CNC programming, measuring tools, and materials. This helps us make better parts with tight tolerances.

- Experience with Tricky Shapes

Complex parts need expert setup skills. At XiHui Aluminium, our team’s years of hands-on work turn high-tech tools into awesome results.

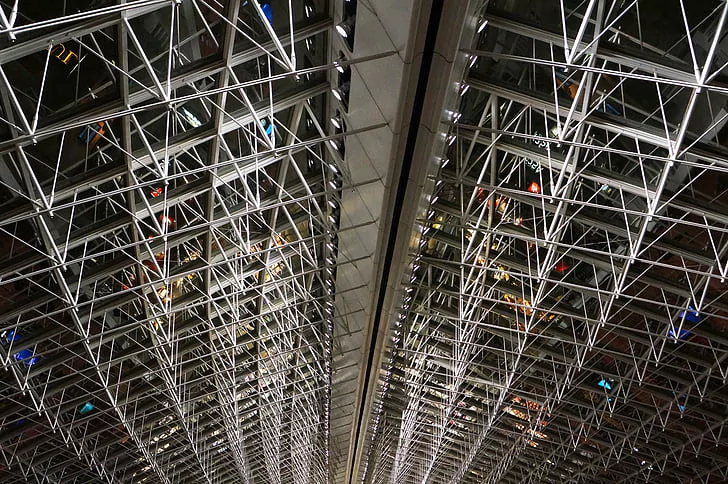

XiHui Aluminium: Your Partner in Precision Aluminum Manufacturing

With 33 years in the game, XiHui Aluminium knows its stuff. We have over 10,000 molds ready to go, so we can start projects fast. With 15 extrusion lines and 40 CNC processing lines, we churn out 20,000 tons a year, serving industries all over the world.

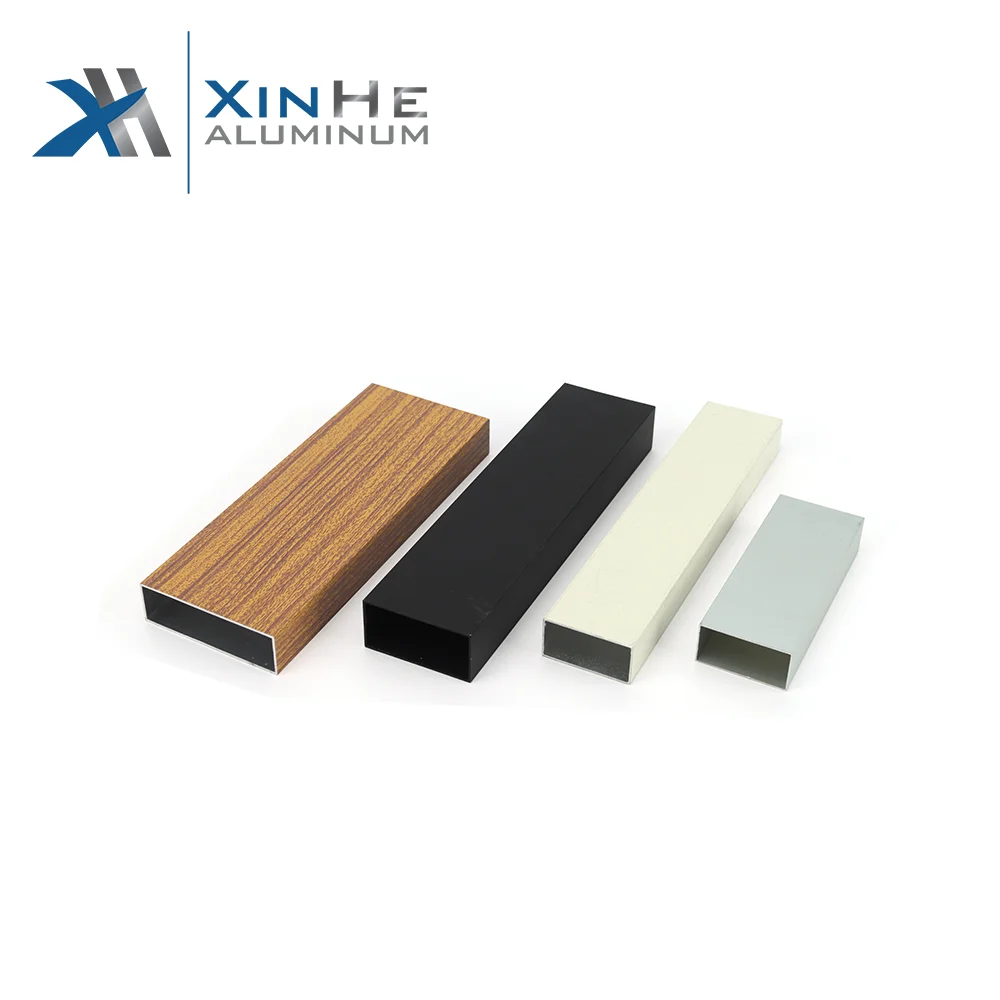

Product Range and Customization Services

We make industrial aluminum profiles and extrusions, like Window & Door Profiles, Kitchen Cabinet Profiles, T-Slots, and Heatsinks. We offer full OEM/ODM services at fair prices, based on your sketches or ideas. For standard items, we don’t have minimum order limits, and we can tweak length or color to fit your needs.

Commitment to Quality and Global Reach

XiHui has a tough quality system and ships fast. A full container order is ready in 25-30 days. New molds take an extra 7-15 days. Our products go to over 120 countries, from automation to buildings, showing we can handle all kinds of projects.

FAQs

Q1: What does ±0.01mm tolerance mean in CNC machining?

A: It means every size has to stay within plus or minus 0.01 millimeters of its target—just a 20-micron range (0.02mm). This kind of accuracy makes sure parts fit perfectly, even in tough situations.

Q2: Can XiHui Aluminium handle custom CNC machining projects?

A: With 33 years of know-how, we’re pros at custom work. We offer full OEM/ODM services, including making new molds from your drawings or samples, with quick turnaround for prototypes.

Q3: How does temperature affect tight-tolerance machining?

A: Heat makes materials and machines grow or shrink, which can push sizes out of whack. That’s why we keep workshops climate-controlled to hit tolerances like ±0.01mm.