Must-know About Aluminum Profile Standards

Aluminum profile standards play a crucial role in shaping the design and manufacturing of aluminum sections in industries such as construction and electronics. These standards ensure uniformity and excellence in aluminum profiles, which in turn impacts the efficiency and overall quality of the end products. Compliance with these standards not only meets regulations but also ensures that manufacturers produce items that align with consumer needs. Entities such as the Aluminum Association are responsible for establishing these guidelines, which encompass measurements, machinery properties, and production methods.

Here at Xihui Aluminum, we take pride in our dedication to crafting top-notch aluminum profiles with a focus on excellence in manufacturing processes. Our wide selection of premium-quality aluminum profiles is designed to meet industry benchmarks for durability and dependability across applications. By prioritizing accuracy and efficiency, Xihui offers tailored solutions for aluminum extrusion to meet the requirements of our clients. Through our state-of-the-art production methods, we ensure that the profiles we create not only meet industry standards but surpass expectations, making them the preferred option for architects and construction professionals alike.

Commonly Used Aluminum Profile Standards

In the production of aluminum profiles, some guidelines are often mentioned. One of these is ASTM B221, which sets out the requirements, for the chemical characteristics of aluminum alloys used in extrusions. Another important standard is EN 755 which details the tolerances and mechanical properties of aluminum extrusions in Europe. The ISO 6360. 2 Standard is essential, for evaluating the quality of aluminum profiles used in applications as it specifically deals with aluminum and its alloys by ensuring they meet the necessary strength and durability requirements.

Key Considerations for Optimal aluminum profiles

Selecting the right aluminum extrusion alloy is crucial to ensure that the profiles perform at the level possible. Various alloys come with features, like strength levels, sizes, and weight capacity to resist corrosion and how well they conduct heat. For example, the 6000 series alloys, like 6061 and 6063 are quite popular because of their ability to resist corrosion and being easy to machine. On the side, the 7000 series alloys are known for their durability. They are often preferred for tasks where having a structure’s key. Choosing the correct aluminum alloy, for your application is crucial as it can greatly affect how well the final product performs over time and its maintenance requirements.

Impact of Extrusion Speed on Profile Quality

The speed at which aluminum profiles are extruded plays a role, in determining their quality and properties. When extruded quickly it can result in a range of problems including surface imperfections, inconsistent profiles, and uneven cooling. This could potentially affect the strength and stability of the end product. The optimal extrusion speed depends heavily on factors such, as the alloy used, die design, and desired profile dimensions. By managing these variables manufacturers can enhance the cooling process. Maintain consistent quality across all profiles.

Fundamental Processes in Aluminum Extrusion

Aluminum extrusion involves converting raw aluminum alloy into a sectional shape through a manufacturing process. The first step is heating the aluminum ingot until it’s malleable to pass through a die that shapes it. The design of this die is crucial as it dictates the profile’s shape and texture. After extrusion, the aluminum profiles go through a cooling stage, to obtain the desired characteristics, like strength and durability.

Throughout the extrusion process, it’s crucial to manage factors, like temperature and pressure carefully as they have an impact on the product’s quality and properties. Inadequate control may result in flaws in the profiles like fractures, deformities, or size inconsistencies. By following process regulations and norms producers can create top-notch aluminum profiles ideal for a range of uses, in construction, automotive manufacturing, electronics, and other sectors.

Key Considerations for Optimal aluminum profiles

When dealing with aluminum profiles’ picking the extrusion alloy is crucial, for getting the performance possible.’ Various alloys have characteristics that affect their suitability for uses.’ For example, the 6000 series alloys like 6061 and 6063 are known for their resistance to corrosion and’ ease of welding ‘. Ability to be machined easily’ making them a top option, for building windows and doors exposed to different environmental conditions.’On the other hand, the 7000 series is commonly utilized in engineering scenarios due, to its durability making it ideal, for structural parts that demand high performance.

When it comes to projects it’s crucial to grasp the application needs. For instance, if saving energy is a concern opt, for alloys paired with breaks to reduce heat transfer resulting in significant advantages for regulating indoor temperatures. In the field of architecture, there’s a growing preference, for aluminum profiles that not only meet performance standards but also cater to preferences, including surface treatments that enhance their visual charm.

At Xihui Aluminum we cater to these requirements by providing a variety of aluminum alloy choices customized to meet our client’s needs. We are dedicated, to upholding standards of quality to guarantee that every profile not only adheres to industry norms but also fulfills contemporary architectural requirements. Through the use of cutting-edge alloys in our offerings, we empower architects and constructors with freedom, in design and functionality enabling the creation of groundbreaking structures that blend sustainability and elegance seamlessly.

Impact of Extrusion Speed on Profile Quality

The speed at which aluminum profiles are extruded is crucial, in determining the quality and physical characteristics of the product. It is important to find the right balance in extrusion speeds as rates can result in issues, like surface imperfections or varying dimensions. Conversely, slower extrusion can improve quality. Might reduce production efficiency and drive up expenses. Manufacturers need to find the mix of speed and quality when considering the properties of the aluminum alloy they are working with and the end profile they aim to achieve.

At Xihui Aluminum Company cosmetic care, in our extrusion methods is key to balancing efficiency with top-notch quality outcomes. Our advanced production facilities empower us to regulate cooling rates to maintain the durability of aluminum profiles. By observing variables like temperature and pressure during extrusion operations we guarantee uniformity, in every profile manufactured to adhere to the high industry norms.

Our focus, on maintaining standards guarantees that the aluminum profiles we produce meet both demands and technical standards required for different uses effectively. Our dedication to accuracy results in profiles that uphold their integrity, durability, and performance quality term making installation easier for workers and improving overall utility, for end users.

Fundamental Processes in Aluminum Extrusion

The production of aluminum extrusion involves a process that converts raw aluminum alloy, into profiles using carefully managed steps. It begins by heating the aluminum ingot until it reaches a state to pass through a die. The shape and surface finish of the profile are influenced by the design of this die impacting both its functionality and appearance.

When extruding materials, like aluminum profiles it’s crucial to keep the balance of heat and pressure in check for a successful process outcome. Little heat can lead to incomplete or weak extrusions while too much pressure can result in uneven dimensions or flaws, in the profile shape. Manufacturers have the power to tweak these factors to their advantage which not only affects how fast the extruded material cools down but also determines the strength and structural properties of the aluminum profiles.

Xihui Aluminum: A Market Leader in High-Quality Profiles

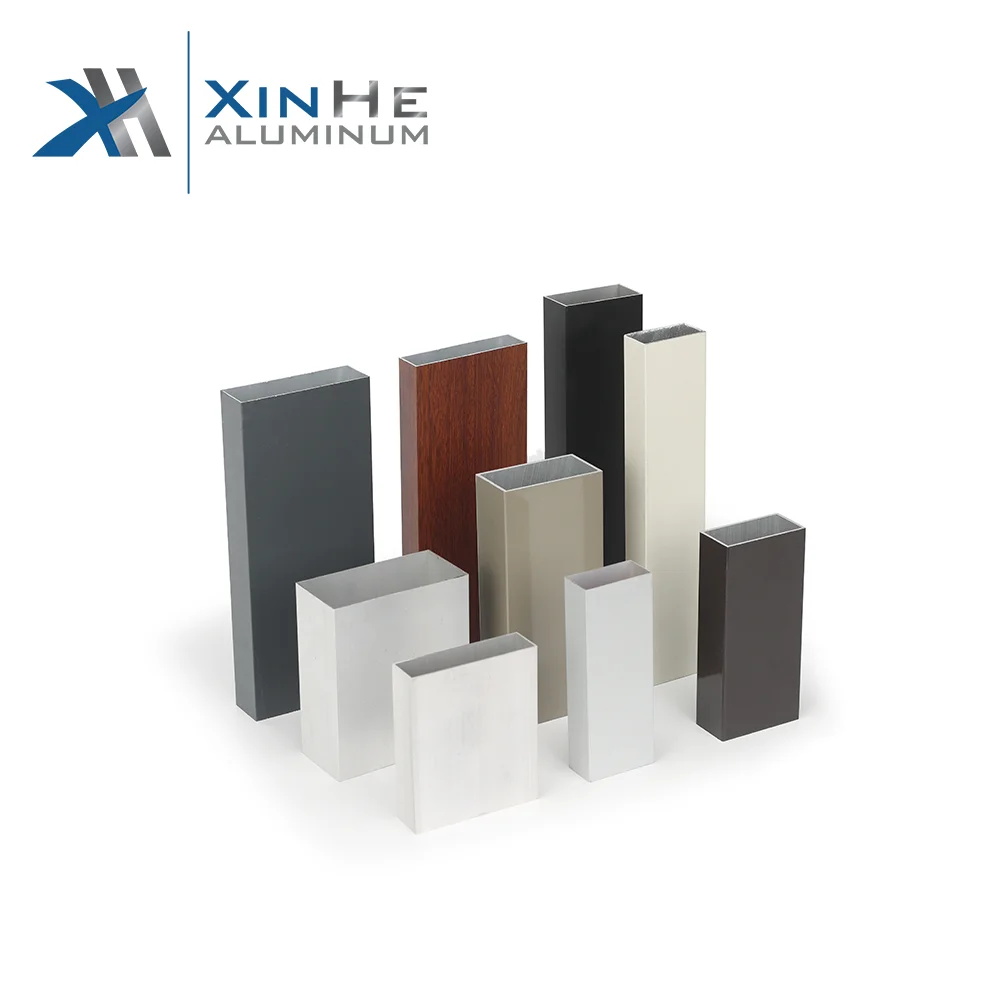

XihuiAluminum Company’s core is dedicated, to producing top-notch aluminum profiles that excel in quality and performance standards within the industry landscape. With a selection of aluminum profiles tailored for purposes ranging from sophisticated architectural projects to practical industrial applications, Xihui excels in crafting innovative solutions that improve product longevity while enhancing visual appeal, through cutting-edge manufacturing methods.

At Xihui Aluminum core services lie in our tailor-made aluminum window and door options that can be personalized to suit needs and preferences perfectly. We offer a variety of frame designs in shapes and sizes along, with configurations like casement windows or sliding doors to cater to the creative visions of architects and builders while prioritizing energy efficiency. Our range of aluminum swing doors, with glass panels, embodies a blend of aesthetics and practical functionality that aligns with the requirements of today’s architectural styles.

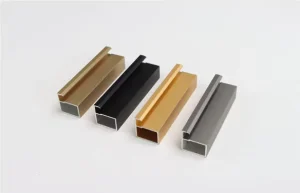

In addition, to that our unique aluminium windows with insulation make use of state-of-the-art materials to reduce heat transfer effectively This helps in creating cozy indoor spaces that meet the energy efficiency needs of homeowners The variety of aluminum products we offer is enhanced by different surface treatment choices such as powder coating and anodizing which improve both the appearance and functionality of the profiles Therefore Xihui Aluminum not only meets industry norms but also surpasses clients’ desires, for flexible and top-notch aluminum profiles.