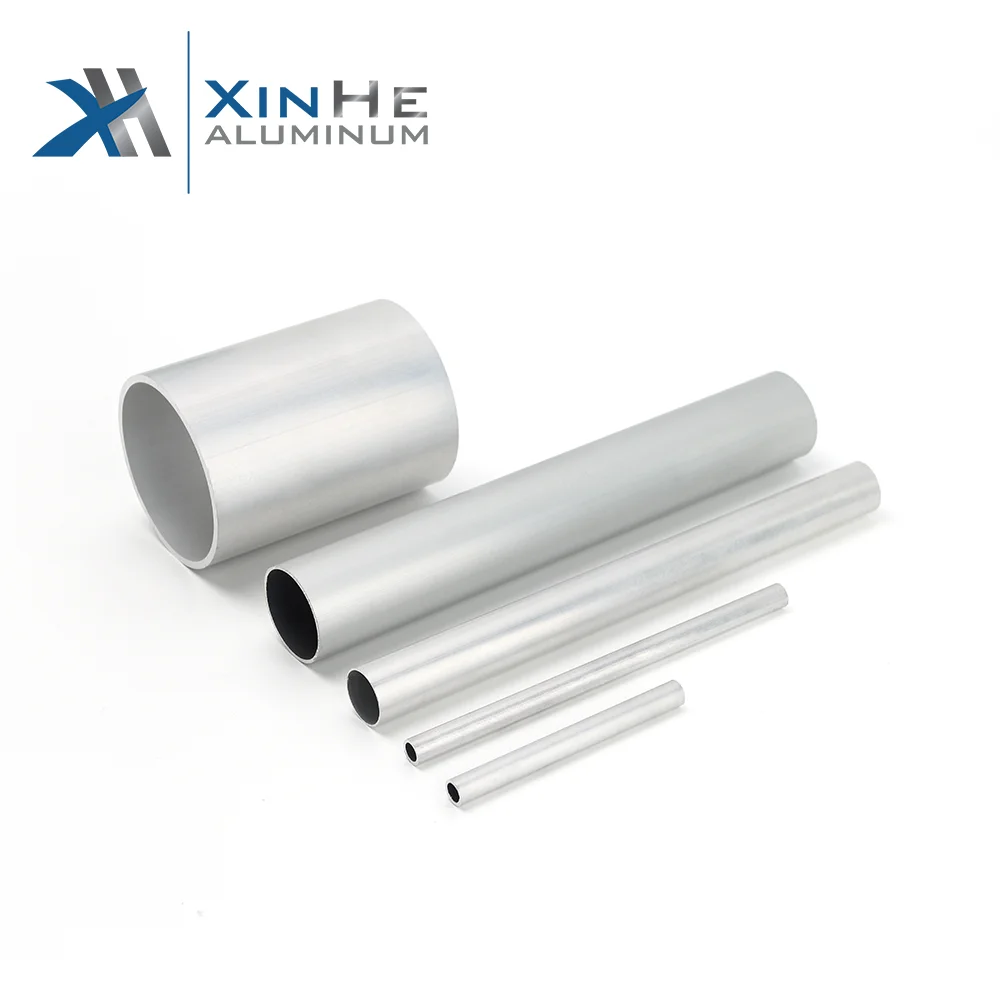

The demand for lightweight yet high-strength components has grown sharply in areas like aerospace, automotive, and electronics, which has sped up the broad use of aluminum alloys. They shine because of their great strength-to-weight balance, strong rust resistance, and good heat flow. Industrial aluminum profiles are alloy materials mainly made from aluminum. Aluminum rods go through heating until they melt, then get squeezed to form aluminum pieces with varied cross-section shapes, but the mix of added alloys differs. So, the mechanical traits and uses of these industrial aluminum profiles vary too.

CNC machining boosts aluminum’s value by allowing very exact tailoring, which matters a lot in top-performance areas. There, gaps must stay tiny, within microns. So, specially made CNC–machined aluminum profiles for key industries become vital.

Importance of CNC Customization in Aluminum Alloy Applications

CNC machining goes beyond just making things, which serves as a key way to bring ideas to life. Engineers can turn CAD designs into real parts with accuracy down to under a millimeter, and this precision proves essential in cases that need custom strength in structure, heat handling, or looks. And because of on-demand CNC services, quick testing of prototypes and small runs now works well, even for tricky shapes. Our setup, certified under ISO 9001, makes sure parts last long, stay light, and resist rust well while conducting heat nicely, which gives a big edge in cycles where products keep getting tweaked.

What mechanical weaknesses limit aluminum alloy performance in extreme conditions?

Aluminum has many pluses, but its fatigue strength sits lower than steel’s by nature. In situations with lots of load cycles, like parts in aircraft wings or car suspension setups, tiny cracks can start and slowly grow, which leads to breakdowns over time. So, designers often add more thickness to sections or use treatments on the surface. Yet, these steps can cut into the lightweight that aluminum offers so well.

How does creep behavior restrict high-temperature use?

Aluminum alloys get softer and bend under steady stress when the heat stays high for a long time. That rules them out for spots like engine blocks or turbine cases, where heat keeps coming without stop. Even tough types like 7075-T6 face limits from their fairly low melt points and weak hold against creep above 200°C.

Are hardness and wear resistance sufficient?

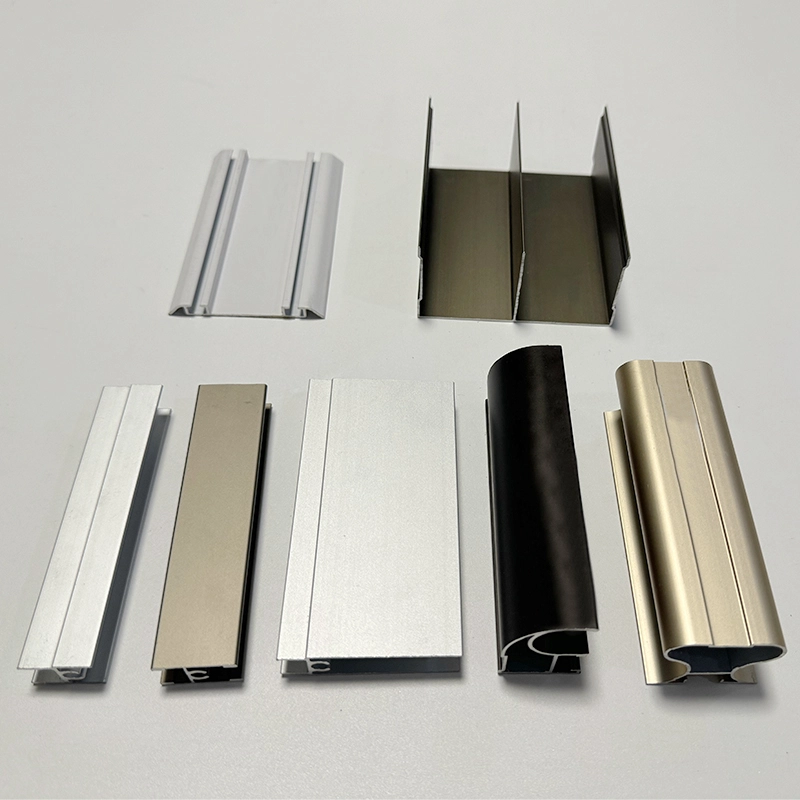

Aluminum stays soft on its own, which causes problems like sticking or scraping when things rub together. Without steps like anodizing or coating, it struggles in places with lots of friction. So, options for surface treatment—such as anodized, powder coated, sand blasted, or polishing—turn crucial to make parts last longer in work settings.

What thermal and electrical limitations should designers consider?

Aluminum expands a lot with temperature changes, which can mess with steady sizes in precise setups. This issue grows big in tools for optics, cases for electronics, or builds where fits must stay tight under shifting warmth.

Why is heat resistance a limiting factor?

Aluminum melts around 660°C, and it starts losing its hold on strength at warmer levels that aren’t even that extreme. Before it fully melts, the inner structure shifts and weakens the whole thing. Thus, it can’t stand alone in hot spots like burn areas or systems that focus sunlight without extra support.

Is corrosion a major concern in aluminum assemblies?

When aluminum touches other metals that differ electrically—mainly in wet spots—galvanic corrosion speeds up fast. The gap in electric potential quickens the rust on the weaker metal, which is usually aluminum, which causes pits and cutting down on its strength over time.

Are natural oxide layers enough to protect aluminum?

Aluminum builds a thin oxide coat that guards it somewhat by nature. However, this shield stays slim and breaks down easily in tough spots like sea air or factory fumes. Our aluminum alloy heat sinks can be anodized for better protection against rust. That way, they hold up well over time, even outside in rough weather.

How does aluminum compare structurally to stronger metals?

Aluminum gets praise for its solid balance of strength against weight. Still, its point where it lags behind titanium or top steels. In builds that carry loads and need little bend under pressure, this shortcoming stands out unless shapes or added elements fix it.

Why is stiffness an issue in critical load applications?

Aluminum’s flex measure, around 70 GPa, means it bends more than steel or titanium with the same push. So, it limits use in items like rods or beams where any give must stay small.

What challenges arise during CNC machining of aluminum alloys?

Aluminum tends to stick to tools, so bits of it pile up on cutters. This wears them out quickly and throws off exact sizes. To keep tools going longer, and tuned speeds for feed matter a lot.

Why does burr formation affect finish quality?

The soft side of aluminum leads to more rough edges during cuts or holes. That calls for extra cleanup steps. Processes like deep CNC drilling, milling, cutting, welding, bending, and putting together make sure the outside meets work standards for looks and fitting.

XiHui Aluminium: Excellence in Custom CNC Aluminum Profile Manufacturing

If you want to beat these material hurdles while keeping exact work and quick time to sell, check out how this CNC machining service for aluminum profiles gives full answers from picking materials to finishing touches.

With more than 40 CNC machines, including ones with 5 axes, and over 80% automation, XiHui Aluminium brings top skills with control to ±0.01mm on tricky shapes. No matter if your plan comes as a STEP file or a real model, they handle made-to-order runs with small starting amounts and fast test builds.

We stand as an aluminum manufacturer in Foshan with over 31 years of know-how since 1993. Their full quality setup picks only top-grade 6000-series alloys with purity above 98%. Plus, every group goes through checks at many points.

What services make XiHui Aluminium stand out?

Their wide range covers milling on 3 to 5 axes, turning pieces, marking details, drilling holes, cutting with lasers, punching shapes, threading, and beyond. These methods handle 98% of what needs doing. They fit goods from LED heat sinks to cases for medical use and profiles for buildings.

Which industries benefit from their expertise?

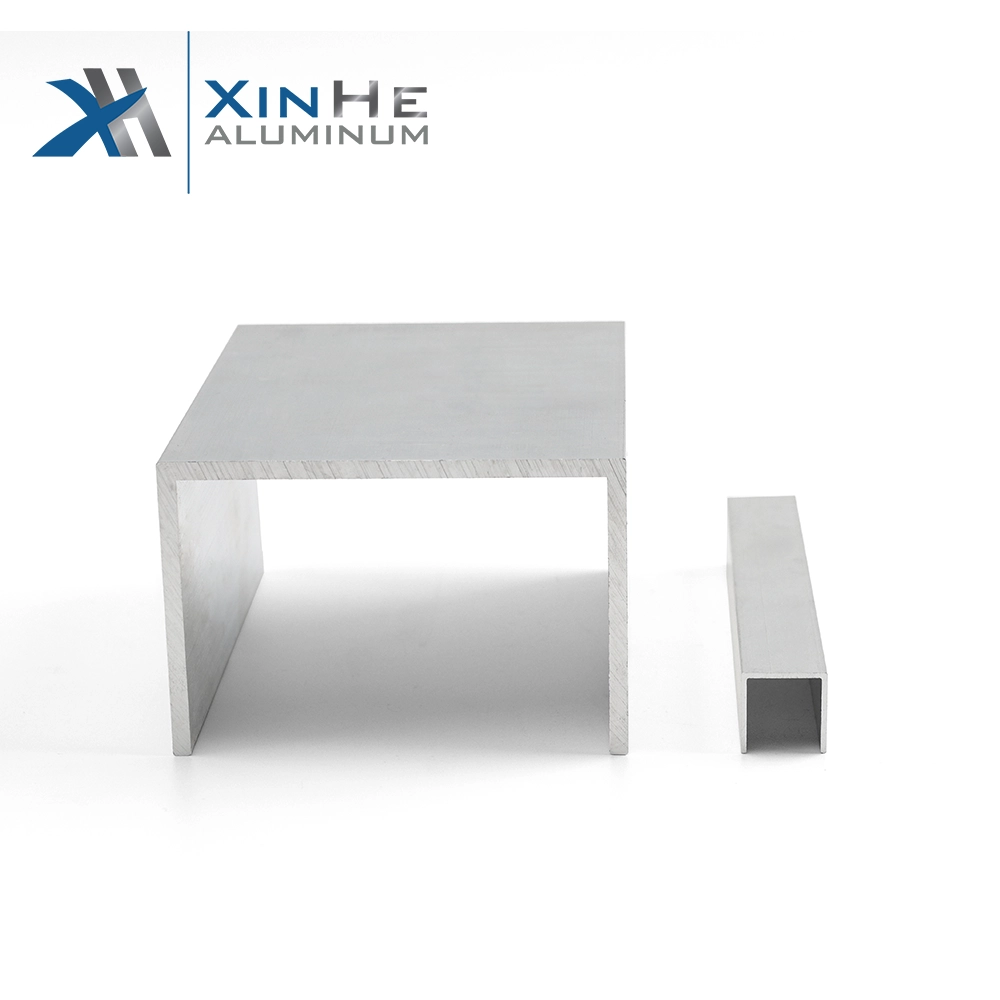

Their tailored profiles help in aerospace with brackets, cars with cooling frames, factories with boxes, handles for cabinets, systems for windows, and more. In general, industrial aluminum profiles mean all aluminum shapes outside of doors, windows, walls, decor inside or out, and building frames. So, frame profiles, box types, radiator profiles, beam profiles for gear, frame types, and all sorts of spare parts and bits count as industrial aluminum profiles.

What surface treatments enhance performance?

They provide anodizing with color choices, powder coating for lasting strength, sandblasting for soft textures, and polishing. Each one fits the spot where the part will work.

Which projects show proven results from custom CNC machining?

Buyers note longer life for their goods thanks to smarter picks in alloys and tight control on finishes. With mold work done in under 7 days, even tiny orders get quick turns. And orders that come back show steady trust from clients over the years.

How seamless is the customer engagement process?

- Upload your design files (PDF/DWG/STEP) or physical sample.

- Receive a quote within 24 hours.

- Prototype delivery possible within just 7 days.

- Post-delivery technical consultation and replacement guarantees reinforce customer confidence.

What improvements are achievable through CNC customization?

Key metrics include enhanced dimensional tolerances that enable smoother assembly. Improved surface finishes mitigate corrosion risks. Adjusted alloy grades optimize the balance between weight and strength. To address high-precision machining needs across diverse industries—from LED thermal modules to structural framing.

Summary Remarks

Aluminum alloys bring real gains in spots where weight counts most, but they show clear shortfalls in harsh pulls or surroundings. Think of short fatigue spans, weak hold against wear without fixes, and shaky hold on heat when temps climb. XiHui Aluminium tackles these issues with strong CNC skills that allow for exact tailoring based on what the job needs. At the same time, they keep tight rules on quality through every step of making.

With years deep in the field, support for small runs that flex, quick builds for tests, and many choices for finishes, XiHui Aluminium helps those who design push past material limits. They do this through fresh ways to carry out plans, using strong aluminum profiles made just right for tough spots.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC–machined aluminum alloy parts?

A1: The MOQ varies depending on part complexity, but generally starts from just 10 pieces per design for standard profiles-ideal for prototyping or small-batch production needs.

Q2: What surface finishing options are available for machined aluminum parts?

A2: XiHui Aluminium offers anodizing (clear/colored), powder coating, sandblasting, brushing, polishing, andelectrophoresis coating — each tailored to enhance corrosion resistance or achieve desired aesthetics.

Q3: How does structured data markup help improve visibility for my product listings?

A3: By integrating schema.org structured data into your product pages (e.g., Product schema with attributes like brand/material/dimensions), search engines can display rich snippets such as ratings or pricing — increasing click-through rates from search results pages significantly.