Today’s smart factories, part of what’s called Industry 4.0, need machines that are super fast, work really well, and are crazy accurate. Picking the right stuff to make these machines is a big deal. Aluminum alloys are a favorite because they’re light but tough, move heat nicely, and don’t rust easily. To make the most of this cool material, you need a clever way to shape it. That’s where custom CNC (Computer Numerical Control) machining comes in. It takes digital plans and turns them into real, top-notch machine parts that follow strict rules.

The Critical Role of Aluminum Alloys in Modern Machinery Manufacturing

Aluminum is popping up everywhere—in robots, automation, and super-precise tools—because it’s got some awesome perks. It’s light, so parts don’t need much push to move. This makes machines zip along faster, start up quicker, and save energy. Plus, aluminum has other neat tricks. It’s great at moving heat, which is perfect for things like heat sinks or electronic boxes that need to stay cool. And it’s not magnetic, which is super important for sensitive medical gear or electronics.

Making these parts isn’t easy, though. Here’s why:

- Really Precise and Strict Rules: Parts like valve bodies, robot arm joints, or sensor cases have to fit just right. They need to be made with teeny-tiny measurements, like super small fractions of a millimeter. This makes sure everything fits together and works smoothly.

- Fancy Shapes: To make parts lighter and better, they often have curvy designs, inner paths, or thin walls. Building them as one piece, instead of sticking bits together, makes them stronger and more trustworthy.

- Mixing Strength and Features: Every part needs something different. A frame might need to be really tough. A moving part might need to handle lots of wear. A part in a rough place needs to fight rust well. Choosing the right aluminum type, like 6061 or 7075, matters a ton.

Custom CNC Machining: The Precision Bridge from Design to Reality

Custom CNC machining handles these tough jobs like a champ. It’s the best way to make awesome aluminum parts that are spot-on, flexible, and can be made in small or big batches.

Achieving Precision Engineering

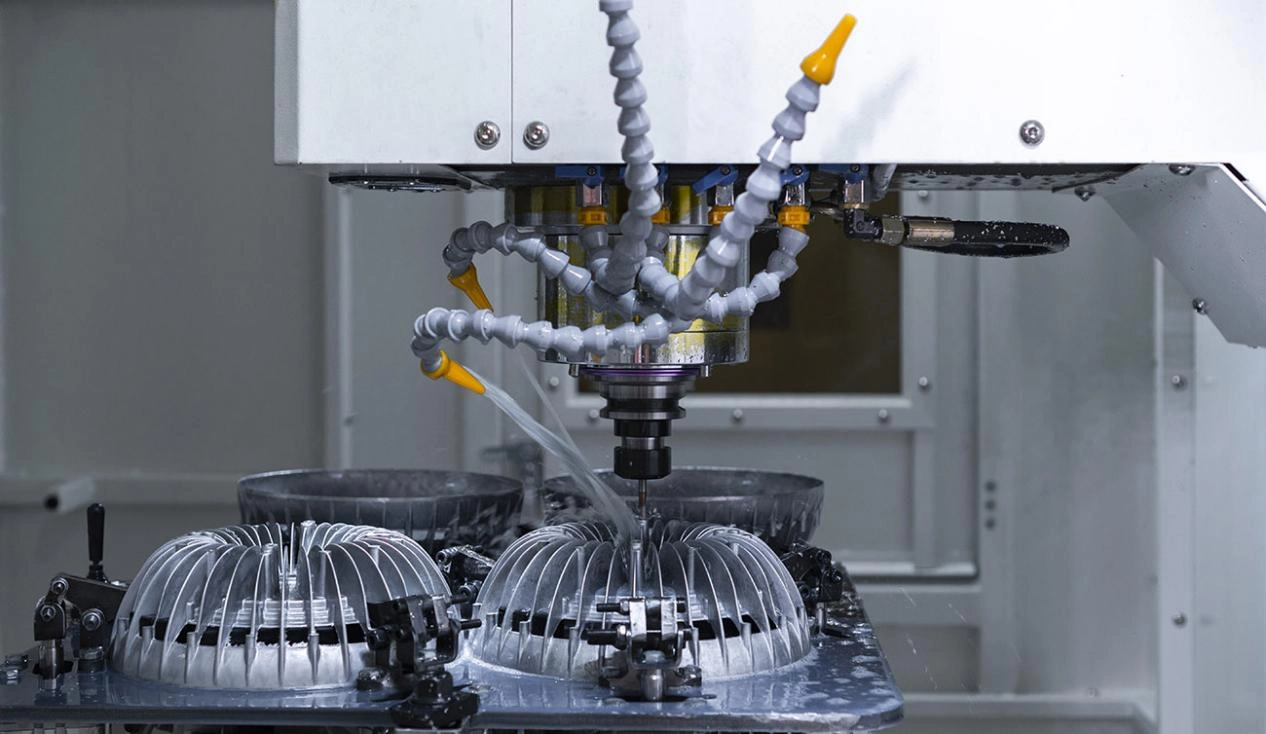

CNC machining is like sculpting with a computer. It cuts away bits of an aluminum block using tools that a computer controls. Cool machines, like 3-axis, 4-axis, or 5-axis CNC centers, can move the block and tool in all sorts of directions at once. This lets them create tricky shapes, slanted holes, or detailed surfaces in one go. So, even the pickiest measurements are nailed every single time.

Unlocking Unlimited Design Freedom

CNC machining lets you dream big. You start with a digital picture, called a CAD model, which gets turned into instructions for the machine. This means if you can draw it, you can probably make it. It’s perfect for whipping up test parts fast, so you can try ideas and fix them quick. For example, think about a fancy bracket. It used to need lots of pieces glued or bolted together. Now, you can carve it from one aluminum block. That single piece is tougher, lighter, and way more accurate.

Flexibility in Material Selection

Different machines need different kinds of aluminum. CNC machining is great because it works with all sorts of aluminum types, so you can pick the perfect one:

- 6061-T6: This is a super popular pick. It’s tough, easy to shape, doesn’t rust much, and isn’t too expensive. It’s awesome for frames, base plates, and all kinds of machine parts.

- 7075-T6: This one’s crazy strong, almost like some steels. It’s great for parts that get a lot of stress, like robot bits, gears, or high-pressure fluid systems.

- 5052: This type is amazing at fighting rust, especially in harsh spots like the ocean or chemical plants. It’s perfect for special gear.

Seamless Scalability from Prototype to Production

CNC machining is super flexible. You can use the same setup to make one test part or crank out thousands for big production runs. Every part comes out exactly the same, from the first to the last. This makes it a solid, wallet-friendly choice for small or medium batches.

About XiHui Aluminium: Your Expert Aluminum Manufacturing Partner

XiHui Aluminium has been doing this for over 15 years. We’re pros at shaping aluminum and doing super-precise CNC machining. We offer a full package, helping you from your first idea to the finished part. We can design molds, shape raw aluminum, do fancy CNC machining, and add all kinds of surface finishes. This all-in-one setup makes things easier, keeps quality high, and gets your parts to you fast. As an ISO 9001 certified company, XiHui Aluminium makes top-quality aluminum parts that meet the tough needs of the global machinery world. Want a partner you can trust for your next project? Chat with our engineering team about what you need.

Why Aluminum and CNC Machining Are a Perfect Match

Aluminum and CNC machining go together like peanut butter and jelly. Aluminum’s light weight and toughness make it awesome for today’s machines. But CNC machining is what makes it shine. It cuts with pinpoint accuracy, handles wild shapes, and works with tons of aluminum types. This duo lets you make parts that are strong, light, and super exact—exactly what modern machines need. Plus, CNC machining is quick and bendy, so you can test ideas fast or make lots of parts without losing quality. Think about it: you get parts that fit perfectly and work great, every time.

How CNC Machining Helps All Kinds of Industries

CNC machining with aluminum isn’t just for one type of machine. It’s a game-changer in lots of fields. In robotics, light and tough parts help robots move fast and save power. In automation, super-precise parts keep machines running smoothly without breaking down. In medical gear, aluminum’s non-magnetic trick keeps devices safe and accurate. Even in stuff that needs to stay cool, like electronic boxes, aluminum’s heat-moving skills are a big win. CNC machining makes all these parts possible, no matter how tricky or specific the job is. For example, imagine a robot arm that needs to be light but strong. CNC machining can carve it just right, so it works perfectly.

Real-World Examples of CNC Machining in Action

Let’s make this real. Picture a factory making robots for assembling cars. They need parts that are light, so the robots can move fast, but also tough to handle heavy jobs. CNC machining takes a block of 7075-T6 aluminum and shapes it into a perfect arm joint. It’s strong, light, and fits like a glove. Or think about a medical scanner. Its parts need to be non-magnetic and super precise. CNC machining uses 6061-T6 aluminum to make a sensor case that’s spot-on and safe. These examples show how CNC machining turns big ideas into real, working parts.

Conclusion

To sum it up, aluminum alloys are a huge deal for building better machines. They’re light, tough, and have all sorts of cool features that push the machinery world forward. But it’s custom CNC machining that really makes them pop. It turns aluminum into trusty, fancy, and super-accurate parts that machines count on. Teaming up with a skilled partner like XiHui Aluminium, who can handle everything from shaping to finishing, doesn’t just give you great parts. It gives you a leg up, making your products fresh, high-quality, and ready to stand out in the market.

Frequently Asked Questions (FAQs)

Q1: What is the minimum order quantity (MOQ) for custom aluminum CNC machining?

A1: We’re super flexible to fit all kinds of projects. For test parts or early tries, we can make just one piece (MOQ=1). For bigger batches, the best amount depends on stuff like how tricky the part is or how long it takes to set up. We work with you to find a cheap, smart way to handle small or large orders.

Q2: What are the surface finish options for CNC machined aluminum?

A2: We’ve got tons of surface treatments to make parts work better and look cool. Here are the top ones:

- Anodizing (Type II & III): Makes parts resist rust, get tougher, and come in fun colors.

- Powder Coating: Adds a strong, colorful layer to protect the part.

- Sandblasting (Bead Blasting): Gives a smooth, non-shiny look.

- Brushing & Polishing: Makes a pretty, satin or shiny finish.

- As-Machined: The normal finish with tiny tool marks you can see.

Q3: Which aluminum alloy is best for my machinery parts?

A3: The right alloy depends on what your project needs. 6061-T6 is a great all-around choice, with solid strength, easy shaping, and low cost. For parts that get tons of stress or need to be super tough, 7075-T6 is the way to go. For parts in rough, rusty places, 5052 is awesome. Our engineering team can chat with you about your design and needs to pick the best material.