XiHui Aluminium leads the way in making custom aluminum parts for electronic devices. As the electronics world aims for smaller, better-working gadgets, the need for carefully built enclosures grows bigger. From smartphones and routers to factory control units and medical tools, these enclosures shield inner parts. They also help with tasks, heat control, and nice looks.

Why Aluminum Alloy is a Preferred Material for Enclosures

Aluminum alloy is a favorite because it’s strong but light, fights rust, and moves heat well. It’s also easy to shape, making it great for building detailed enclosures with exact sizes. These features make aluminum enclosures perfect for high-working electronic gadgets.

The Role of Custom CNC Machining in Achieving Design Accuracy

To meet the tough needs of modern electronics, companies turn to custom CNC machining. This method forms aluminum alloys into tricky shapes with very small mistakes. It makes sure every enclosure matches design plans or sample pieces exactly.

Precision and Customization in CNC Machining

Custom CNC machining brings lots of good things when making aluminum enclosures for electronic gadgets.

High Dimensional Accuracy and Tight Tolerances

CNC machines use digital plans to get super exact sizes—often within ±0.01 mm or better. This exactness is key for parts that must fit together well or work with delicate electronics.

Flexibility in Complex Geometries and Design Features

Unlike old ways, custom CNC machining handles tough designs like undercuts, deep pockets, or odd shapes. This lets companies add many uses into one enclosure without losing strength.

Enhanced Heat Dissipation and Structural Integrity

Aluminum carries heat well. Careful machining adds things like heat sinks or air holes right into the enclosure. This boosts cooling while keeping the structure tough.

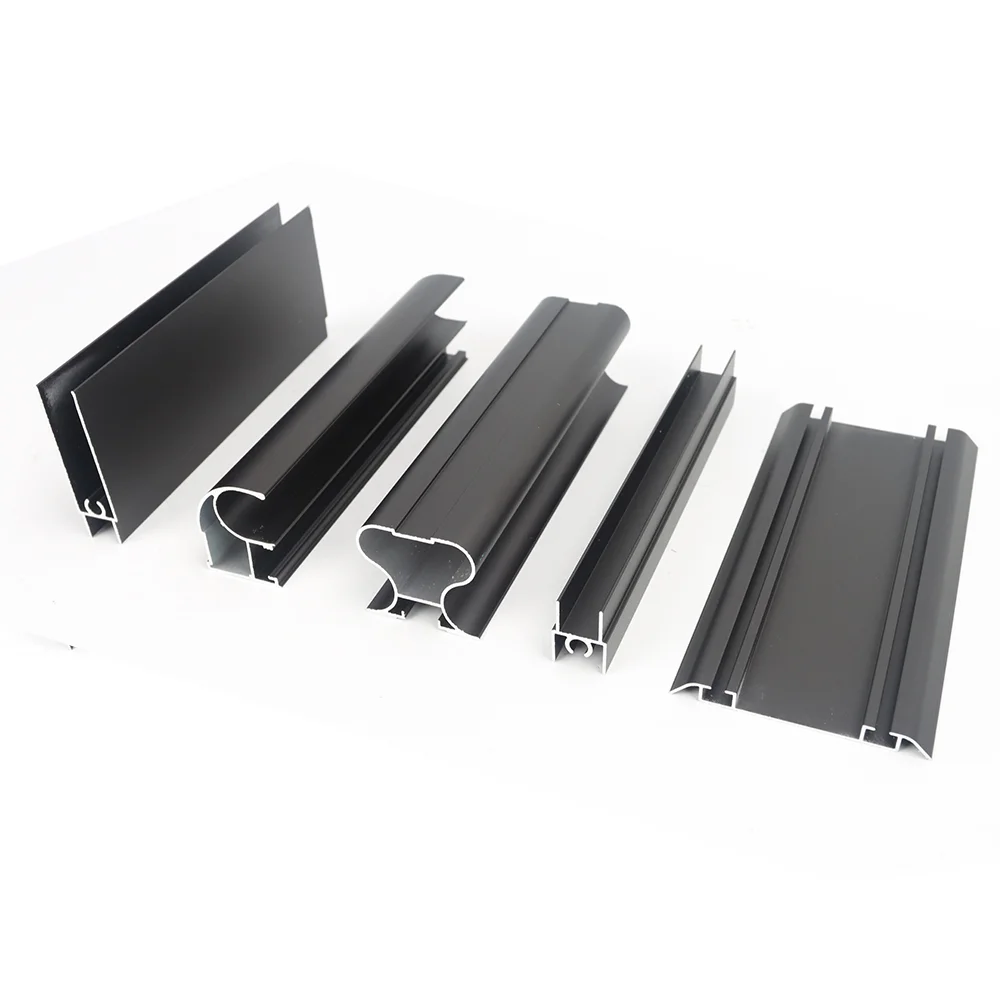

Compatibility with Various Surface Finishes

Machined aluminum can get many finishes—anodizing, powder coating, or bead blasting. These make it look better, fight rust, or add electric insulation.

Critical Factors in Designing Custom CNC-Machined Aluminum Housings

When building a custom aluminum enclosure, several things make sure it works great and is easy to make.

Material Grades and Their Application Suitability

Different aluminum types have special qualities. For example, 6061-T6 mixes strength and easy shaping. But 7075 is stronger, though it’s harder to machine.

Wall Thickness, Mounting Features, and Ventilation Considerations

Even wall thickness keeps the enclosure steady and stops bending during machining. Designers also plan for mounting spots or flanges. They add air holes or slots if cooling matters.

Integration of Functional Elements (e.g., Ports, Threads, Grooves)

CNC machining adds things like threaded holes for screws, cable ports, or grooves for seals. These are made exactly, so no extra work is needed.

CNC Machining Process Overview for Aluminum Alloy Components

Knowing the steps from design to finished part shows how custom CNC machining gives exact results.

From CAD Modeling to Final Product

It starts with a clear digital design that sets all sizes and features of the enclosure.

CAD File Preparation and DFM Review

Before starting, engineers check the digital design. This step, called Design for Manufacturability, finds problems that could slow making the part.

Tool Path Programming and Setup

Using special software, tool paths are made from the design. These guide cutting tools during machining.

Multi-Axis Machining Operations

Fancy CNC machines use 3, 4, or even 5 axes. They reach tricky angles without moving the part by hand. This saves time and keeps sizes right.

Post-Processing and Deburring

After machining, parts are smoothed to remove sharp bits or burrs. Then, they’re cleaned before getting finishes.

Surface Treatment Options for CNC-Machined Aluminum Parts

Finishes make parts look nice and add helpful benefits like rust protection or insulation.

Anodizing (Clear, Color, Hardcoat)

Anodizing adds a strong layer to aluminum. Clear anodizing keeps the metal’s natural look. Colored anodizing adds style. Hardcoat anodizing is extra tough for rough places.

Powder Coating and Painting

Powder coating adds a thick layer that fights for scratches and sun damage. Painting gives shiny or flat looks for more choices.

Bead Blasting, Brushing, and Polishing

Bead blasting makes a smooth, non-shiny look. Brushing adds fine line patterns. Polishing makes surfaces super shiny, great for fancy electronics.

Chemical Conversion Coating (Alodine)

Alodine boosts rust resistance while keeping electric flow. It’s good when parts need grounding and protection from rust.

Quality Control Measures in Custom CNC Machining

Strict checks make sure every enclosure works well in its job.

Dimensional Inspection Techniques (CMM, Calipers, Optical Scanners)

Tools like coordinate measuring machines, digital calipers, and laser scanners check sizes against design plans at different steps.

Surface Finish Evaluation Standards (Ra Values)

Surface smoothness is checked with Ra values. This keeps quality steady, especially for parts like seals or sliding bits.

Compliance with Industry Certifications and Tolerances

Makers follow rules like ISO or client needs. This is super important for fields like medical tools or aerospace.

Tailored Solutions Based on Project Requirements

Every electronic enclosure is different, so the making process should be too.

Adapting to Specific Electronic Device Dimensions and Functions

Custom CNC machining shapes each enclosure’s size, form, and ports to fit specific circuit boards or use settings exactly.

Collaborative Engineering Support for Prototyping to Mass Production

From early test models to big production runs, XiHui Aluminium gives full help. The team shares design tips based on years of know-how.

Scalability for Low-Volume or High-Volume Manufacturing

Whether clients need one test piece or thousands each month, XiHui Aluminium’s flexible setup handles small custom orders and big production runs.

XiHui Aluminium: Your Partner in Precision CNC-Machined Aluminum Solutions

Picking the right partner makes a big difference for great results in custom CNC machining. XiHui Aluminium is great at custom processing with fast CNC lathes and multi-axis milling centers.

Skilled Team and Precision Standards

With strong skills and workers who know materials and engineering, XiHui Aluminium makes sure every part meets tough industry rules. For example, flatness can stay within ±0.01mm when needed. The company offers lots of finishes like anodizing (clear, color, or hard), sandblasting, and powder coating based on what clients want.

Comprehensive CNC Services

Services cover turning, milling, drilling, and tapping, plus custom fixture making when needed. Whether you give drawings or samples, XiHui Aluminium delivers exactly fitted parts. These are backed by careful checks, including first article inspection reports if you ask. The team answers fast—quoting in hours and sending samples quickly to keep your project moving.

Global Reach and Fast Support

To learn more, use our online consultation platform. We serve clients all over the world, delivering top-notch aluminum enclosure making through custom CNC machining. Choose XiHui Aluminium as your trusted partner today.

FAQs

Q1: What types of aluminum alloys are best suited for CNC-machined electronic enclosures?

A: Common picks include 6061-T6 for its good mix of strength and easy shaping. 5052 fights rust well. 7075 is stronger but harder to machine exactly.

Q2: Can I get a prototype before committing to full-scale production?

A: Yes. XiHui Aluminium makes test models fast. This lets clients check fit and use before ordering lots, which is great for testing phases.

Q3: How does surface finishing affect performance?

A: Finishes like anodizing stop rust. Bead blasting makes things look nice. Chemical coatings keep electric flow. Each is picked based on your gadget’s real-world needs.