High-power stage lighting creates stunning visual effects in concerts, theaters, and architectural displays that draw crowds every night. Tech pushes lights brighter and tinier. Heat control turns key. Custom aluminum heatsinks manage temps in these demanding setups effectively.

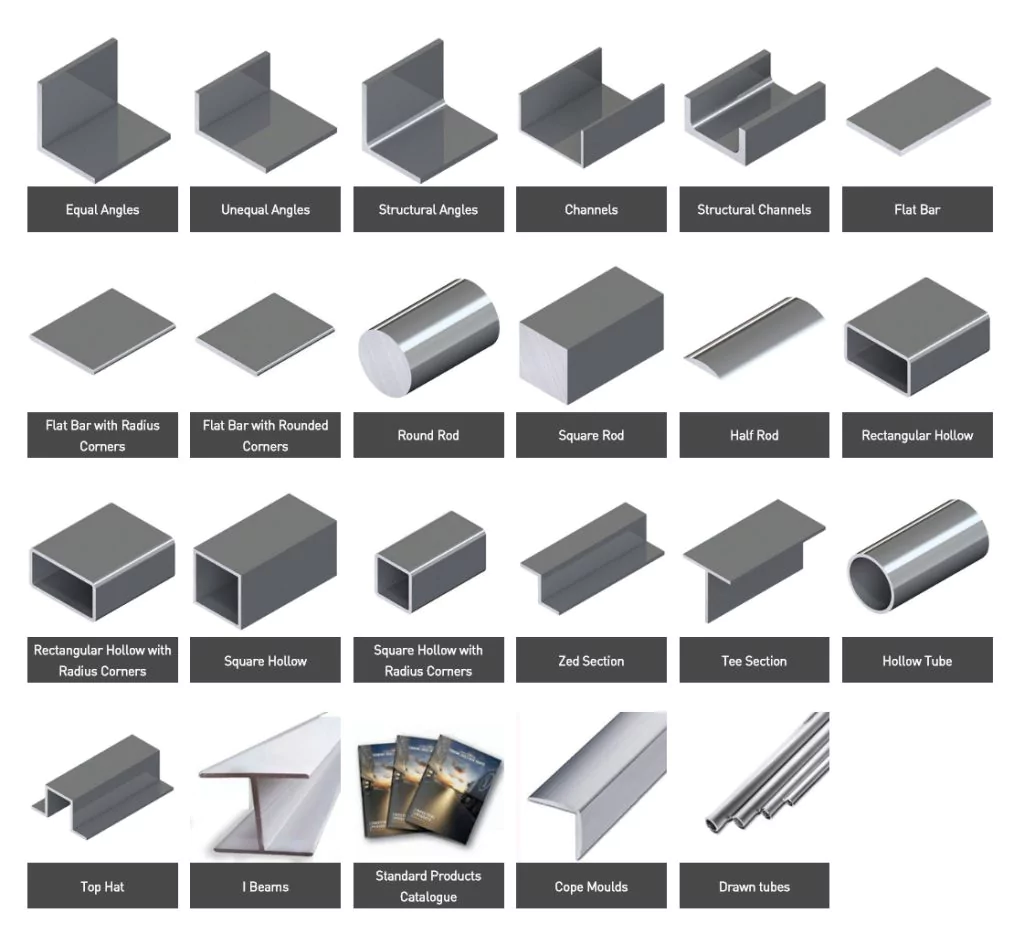

Precision counts hugely for thermal parts in lighting gear. Small changes in heatsink form slash cooling rates sharply. Failures loom large then. CNC precision machining and custom aluminum extrusions dominate builds for stage equipment now.

Demand surges for smarter, stronger, sleeker light designs across venues. Makers seize custom aluminum options eagerly. These sharpen heat handling and weave into tricky fixture layouts seamlessly.

Challenges in Designing Heatsinks for Stage Lighting

Heatsink design for powerful lights faces steep obstacles right away.

Managing High Thermal Loads in Compact Spaces

Modern stage lights squeeze massive power into slim housings that barely breathe. Heat buildup demands clever heatsinks with refined shapes and smart materials to wick away warmth fast. Efficiency rules here. Compact designs force quick heat escape.

Balancing Weight, Size, and Heat Dissipation Efficiency

Show rigs shun heavy loads that strain cables and crews during setup. Heatsinks must stay feather-light yet gulp heat like pros. Custom aluminum extrusions strike that sweet spot perfectly. They channel heat superbly without piling on pounds. Agility wins shows.

Aesthetic and Functional Integration into Lighting Fixtures

Heatsinks don’t just chill components; they must harmonize with fixture curves for a polished vibe. Airflow paths stay open too. Custom aluminum parts adapt effortlessly to such dual roles. Shapes form freely. Finishes gleam just right. Fixtures thus dazzle in form and function alike.

Material Selection for Performance and Durability

Material choice anchors heatsink prowess from the start.

Advantages of Aluminum in Heatsink Manufacturing

Aluminum reigns supreme in heatsink production for its smart mix of heat flow, slim profile, and wallet-friendly price tag.

Thermal Conductivity and Lightweight Properties

Aluminum shuttles heat away swiftly through its core without the drag of heavier metals like copper or steel. Hanging lights benefit hugely from this edge in overhead rigs. Loads lighten up. Safety soars as a result.

Corrosion Resistance and Surface Finishing Options

Anodizing seals aluminum against rust and daily grinds that plague gear in sweaty arenas or rainy outdoor spots. Durability stretches long. Finish choices span broad too—from matte to mirror—for any venue’s flair.

Comparing 6061 vs 6063 Aluminum Alloys for Heatsinks

6061 alloy boasts beefier strength and smoother cuts, suiting CNC precision machining tasks that need rugged holds. 6063 edges out in silky surfaces ideal for elaborate extrusions where looks matter most. Both serve heatsinks well. Choices hinge on power versus polish demands.

Custom Aluminum Extrusions for Efficient Heat Dissipation

Custom aluminum extrusions fine-tune heatsinks down to the finest detail for peak performance.

Benefits of Using Custom Extrusions in Heatsink Design

Engineers mold custom aluminum extrusions to match exact lighting quirks with pinpoint control.

Enhanced Surface Area and Airflow Optimization

Extruded fins and grooves explode surface space to snag more air for convection chills that bite deep. Heat flees faster. Simple ridges yield massive cooling gains in tight spots.

Design Flexibility for Complex Geometries

Such versatility knits heatsinks to brackets or frames without a hitch in the overall build. Curves twist wild. Fixtures merge as one sleek unit under the lights.

Applications in LED and High-Intensity Discharge (HID) Lighting Systems

LEDs and HIDs churn out fierce heat waves that dim outputs if unchecked for hours on end. Custom extruded aluminum heatsinks vacuum it all away reliably. Brightness holds firm. Lifespans stretch far. Shows thus blaze without a stutter.

The Role of CNC Precision Machining in Heatsink Fabrication

CNC precision machining elevates plain extrusions into elite thermal warriors ready for the spotlight.

How CNC Machining Enhances Dimensional Accuracy and Consistency

CNC-carved heatsinks lock in exact measures that outshine sloppy casts or stamps from old-school shops. Fits click perfect every time. Batches roll uniform. Flaws fade out completely.

Multi-Axis Machining Capabilities for Intricate Designs

Multi-axis tools carve twisted feats like bolt holes, glide slots, or breeze ducts that defy basic mills. Details pop alive. Designs leap beyond flat limits with ease.

Tolerance Control and Repeatability in Mass Production

CNC clamps tolerances razor-thin so huge runs spit out clones that perform identically under stage fire. No drifts creep in. Trust builds high.

Integration with Extrusion Processes to Create Hybrid Components

Blending extrusion’s bulk speed with CNC’s sharp tweaks births hybrid heatsinks that save cash yet flaunt flair. Costs dip low. Custom aluminum parts tailor-fit light rigs spot-on.

Surface Treatments and Finishing Techniques

Finishes amp up heatsink grit and gloss in equal measure.

Anodizing for Improved Corrosion Resistance and Heat Emission

Anodizing layers armor against bites from salt air or spills that corrode lesser metals over gigs. Emissivity ticks up slightly for bonus still-air dumps too. Shields hold tough. Cooling whispers stronger.

Powder Coating, Polishing, and Other Aesthetic Enhancements

Powder layers bake on tough hues, while buffs or brushes craft sheens that sync with fixture themes from sleek black to faux oak grains. Styles span wild. Brands beam proud in any hall.

Quality Control and Testing Procedures

Pro lights brook no weak links; heatsinks prove ironclad through every check.

Thermal Performance Testing Standards for Heatsinks

Rigs blast full loads to mimic marathon shows, tracking temps that must stay cool for shifts without a spike. Standards bite hard. Safe ops lock in.

Inspection Techniques to Ensure CNC Machining Accuracy

Coordinate machines probe every inch against blueprints drawn for light-tight tolerances that seal assemblies flawlessly. Scans miss nothing. Precision stands tall.

Applications of Precision-Machined Heatsinks in Stage Lighting Systems

Precision heatsinks fuel entertainment realms from raucous crowds to quiet stages alike.

Use Cases in Concerts, Theaters, and Architectural Installations

Concert trusses hoist banks of lights high where heat sinks keep beams steady amid thumping bass. Theaters tuck them discreetly into grids for subtle glows that set moods. Facades pulse alive on skyscrapers without thermal tantrums. Flows never falter. Vibes ignite endless.

Examples of Integration with Smart Lighting Technologies

Smart setups cram sensors and Wi-Fi brains into housings that also birth LED fire, so heatsinks cradle all while venting dual heats wisely. Space shrinks smart. Tech weaves tight without overloads.

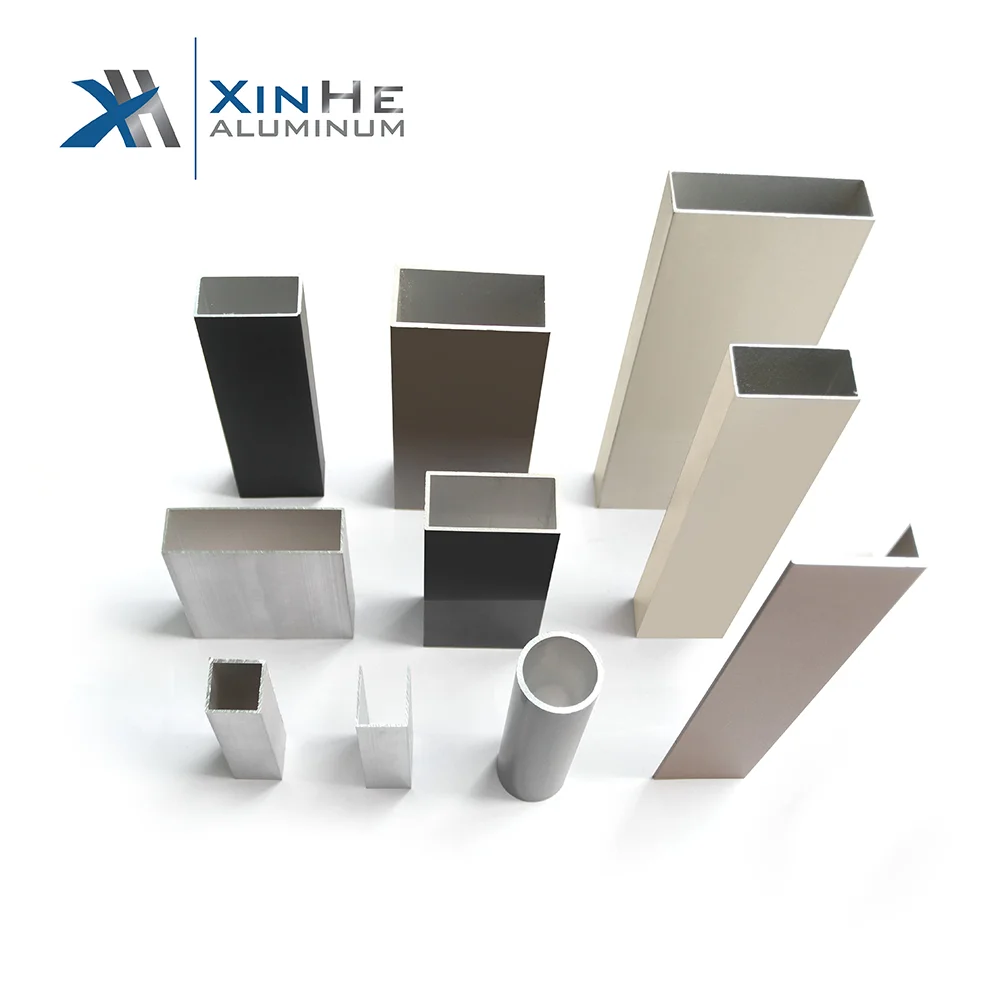

Introducing XiHui Aluminium: Your Partner in Custom Aluminum Solutions

XiHui Aluminium spearheads custom aluminum extrusions and CNC precision machining for niches like stage lighting that crave exact fits.

Overview of XiHui Aluminium’s Manufacturing Capabilities

Three decades-plus of crafting and shipping yield mold libraries numbering in the tens of thousands, with fresh ones spun quick to client blueprints.

Expertise in Custom Aluminum Extrusions and CNC Machining

From T-slot rails to bespoke heatsinks, XiHui Aluminium wields extrusion and cut savvy honed over years in the trenches. Depth runs deep.

ISO-Certified Facilities and Global Clientele

ISO stamps grace plants that feed far-flung buyers with flex schedules for one-offs or floods alike. Stock zips out doors in three to five days flat. Speed serves all.

Product Range Including Heat Sinks, Profiles, Enclosures, and More

Shelves stock modular shells, pegs, bars, and carved completers that bolt into automation or stage worlds without a fuss. Options overflow.

Commitment to Innovation, Quality, and Customer Support

Engineer squads sketch joins and tweaks from raw client sketches, delivering dialed-in fixes that click from the jump. Needs nail down. Wins stack high.

FAQs

Q1: What makes custom aluminum extrusions ideal for stage lighting heatsinks?

A: They twist shapes to max heat grabs via vast skins while shaving weight for safe sky hangs. Flex dominates.

Q2: How does CNC precision machining improve heatsink performance?

A: It carves true scales, echoes builds faithful, and slots perks like peg points or gust lanes that hone ops and bonds. Peaks rise clear.

Q3: Can XiHui Aluminium help with both design and manufacturing?

A: Absolutely. They forge custom aluminum parts from scratch. Engineers map draws and hacks off client briefs too. Full circle aid.