The electric vehicle (EV) industry surges with massive growth these days. This rapid expansion stems from the global push toward cleaner, more sustainable ways to get around. As EVs pop up everywhere on roads and in showrooms, folks crave custom battery enclosures more than ever before. These clever housings cradle and defend the battery packs that give electric cars their zip and power. They lock in safety, crank up efficiency, and stretch out the life of those packs. No wonder they’re a cornerstone in every EV build line.

Why Aluminum Is a Preferred Material for EV Battery Pack Housings

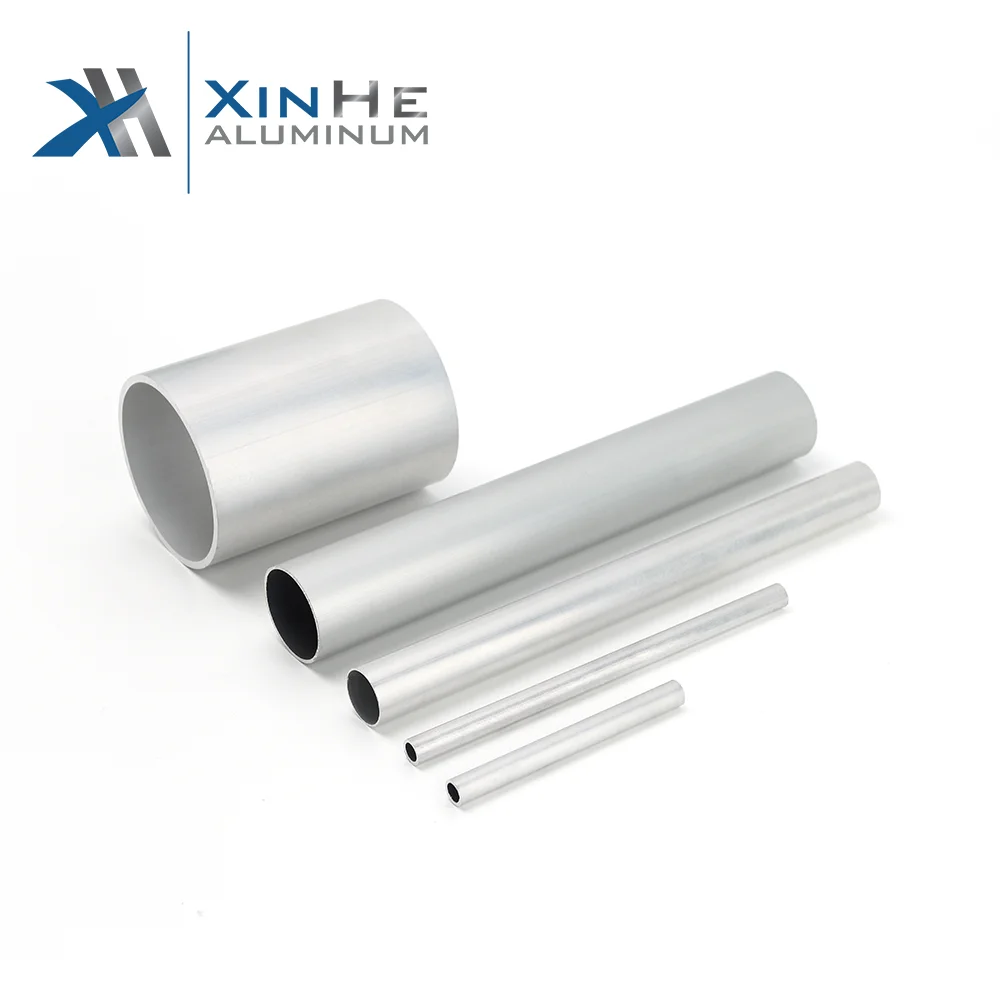

Aluminum grabs the spotlight for EV battery housings without a doubt. It delivers rock-solid mechanical strength all while keeping things feather-light in weight. That combo skyrockets vehicle performance and squeezes every drop of energy efficiency from the system. On top of that, aluminum excels at thermal conductivity. It whisks heat away from battery cells in a flash. Overheating becomes a thing of the past. Operations run smooth and cool under pressure.

The Role of Precision CNC Milling in Advanced Manufacturing

Precision CNC milling takes center stage in cutting-edge manufacturing setups. It truly excels when it comes to whipping up custom aluminum components tailored for EV needs. Manufacturers rely on it to nail those razor-sharp dimensions and super-tight tolerances every single time. Without them, the wild curves and intricate layouts in battery enclosures just wouldn’t click into place.

Key Requirements for EV Battery Enclosure Design

Any enclosure worth its salt nails a handful of core engineering demands head-on. It has to perform like a champ and prioritize safety above all else. Start with the basics. Build it tough.

Mechanical Strength and Structural Integrity

Enclosures for batteries demand ironclad mechanical toughness right from the get-go. They stand guard against nasty jolts and constant road vibrations that come with daily driving. Structure holds the line. It shields those fragile cells inside. Damage or glitches? Blocked cold.

Thermal Management and Heat Dissipation

Handling heat smartly dominates the blueprint for battery enclosure designs these days. Aluminum’s killer thermal flow scatters warmth like nobody’s business across the whole setup. Temperatures inside the pack stay rock-steady no matter what. No more boil-overs. Performance soars higher. Batteries last way longer too.

Weight Optimization and Compact Design

Shedding pounds drives the heart of EV engineering without question. Lighter setups mean better energy use and longer hauls on a single charge every time. Aluminum slashes the vehicle’s total mass big-time, yet it never skimps on raw power or staying power. Designs stay snug and space-smart. Chassis room opens up wide. Everything fits just right.

Corrosion Resistance and Environmental Durability

Enclosures battle brutal outdoor foes day in and day out. Moisture soaks in, chemicals splash around, and temps swing wild from hot to freezing. Aluminum laughs it off with built-in rust resistance that runs deep. Longevity kicks in hard. Reliability never wavers. The battery pack’s guts stay sealed tight.

Precision CNC Machining in Custom Aluminum Parts Manufacturing

This powerhouse process morphs plain aluminum stock into sleek, high-octane finished goods overnight. It maps the full route from blank slate to battle-ready component.

What Is Precision CNC Milling and How It Works

Precision CNC milling taps into machines run by smart computers for the heavy lifting. They slice and sculpt raw materials into exact shapes on command. Coded instructions guide the dance of spinning cutters as they peel away excess. Precision hits peak levels. Consistency rules the output stream.

Benefits of Using CNC Milling for Aluminum Enclosure Fabrication

CNC milling packs a punch with perks that scream quality for enclosure builds across the board. Dimensional accuracy lands dead-center every run. Parts mesh together flawless in even the craziest assemblies out there. Batches roll out identical. Quality sticks like glue through massive production scales. Surfaces gleam buttery-smooth right off the tool. Complex twists and hidden nooks in custom battery enclosures? Handled with ease.

Material Selection: Aluminum Alloys for EV Battery Enclosures

Zeroing in on the perfect alloy locks down how the enclosure struts its stuff in the end. Choices here ripple through performance from day one onward.

Commonly Used Grades: 6061, 6063, and T5 Series

A few aluminum grades dominate the field thanks to their all-around balanced vibes. The 6061 alloy cranks out stellar mechanical traits that shine bright. High strength punches above its lightweight frame, corrosion wards off trouble easy, and welding flows without a hitch. 6063 steps up with surface polish that turns heads. It blends form and function seamless for style-heavy jobs. T5 treatments fire up hardness levels sharp. Ductility hangs in there strong.

Factors to Consider When Choosing the Right Alloy

Battery enclosure picks hinge on juggling strength versus that slim profile tight. Environmental hits like rust threats loom large in the mix. Budget bites matter plenty too. Machinability and finish flair round it out full.

CNC Milling Service Workflow for Custom Enclosure Projects

Streamlined steps keep custom jobs humming from brainstorm to box-out without a single snag. Quality stays laser-focused the whole ride.

From CAD Design to Finished Product: The End-to-End Process

The full manufacturing arc unfolds in crisp, locked-in phases that build momentum fast. CAD platforms spin up virtual twins of the design upfront. Validation runs deep before blades ever touch metal. Programmers plot tool paths next with surgical detail. Machines execute spot-on to the blueprint’s every whim. Deburring sweeps away burrs post-cut. Finishing touches elevate the gleam and grip.

Quality Control Measures in CNC Machining Projects

Inspections swarm every checkpoint like clockwork. Specs get honored to the letter without mercy. Defects drop through the floorboards low. Reliability climbs sky-high. Products emerge battle-tested.

Engineering Challenges in Battery Pack Enclosure Fabrication

These beasts of components throw curveballs that demand ninja-level skills to dodge and weave. Expertise fills the gaps wide.

Managing Tight Tolerances Across Large Surface Areas

Clamping down tolerances on vast expanses stretches even pro setups to the brink sometimes. High-tech machining tricks and real-time monitors jump in clutch. Accuracy holds firm over acres of material.

Integrating Mounting Features, Channels, and Cooling Fins

Designs bristle with bolt-ons, flow paths, and fin arrays that scream complexity loud. Planning turns razor-focused. Execution demands steady hands. Snags vanish. It all meshes perfect.

Balancing Rigidity with Lightweight Construction

Stiff frames meet feather weights in a high-wire act of tweaks and trades. Material flows optimize ruthless. Structures evolve lean yet unyielding. Heft stays minimal.

Surface Finishing Techniques for Milled Aluminum Parts

Machining wraps, but the real glow-up hits with post-game polishes that amp durability, utility, and curb appeal tenfold. Options abound.

Anodizing for Corrosion Resistance and Aesthetic Appeal

Anodizing layers on rust-proof armor while dishing out visual pops in endless hues. Durability surges forward bold. Looks lock in lasting.

Powder Coating, Sandblasting, and Brushed Finishes

Powder coats seal in toughness that laughs at wear and tear over time. Blasts of sand or brush drags craft textures raw or refined on cue. Needs met spot-on.

Functional Coatings for Electrical Insulation and EMI Shielding

Specialized films block stray currents and zap interference dead in key zones. Insulation flows ironclad. Safety nets deploy full.

XiHui Aluminium: Professional Manufacturer of Custom Aluminum Profiles

Hooking up with battle-hardened makers spells success for any custom push you chase. They deliver the goods clean.

Overview of XiHui’s Capabilities in Extrusion and CNC Machining Services

XiHui Aluminium owns the extrusion game and CNC precision like pros born to it. Full-spectrum fixes roll out for heavy industrial hits.

Specialized Solutions for Automotive Applications, Including EV Components

Auto realms fall under our wheelhouse deep, especially EV guts that demand the best. Tailored pieces emerge custom-crisp.

Commitment to Quality, Precision, and Customer-Centric Innovation

Quality anchors everything at XiHui without compromise. Precision trails right behind tight. Innovations bend to your vision sharp. Clients beam. We evolve relentless.

Applications of Custom-Milled Aluminum Enclosures in Electric Vehicles

Enclosures weave into the EV soul, propping up performance and throwing up safety walls thick. They elevate the whole shebang.

Integration with Modular Battery Systems

Custom-milled enclosures dovetail neat into modular battery frameworks built for flexibility. Assembly snaps together swift and sure. Maintenance tweaks happen in a heartbeat too.

Role in Heat Management Systems

Heat control systems lean hard on these enclosures for backbone support. They regulate temps across the pack with finesse unmatched. Output stays peak. Cycles endure.

Contribution to Vehicle Safety Standards

Safety benchmarks get nailed square by enclosures that leave no room for error. Vehicle trust builds layer by layer solid. Passengers ride shielded. Reliability echoes loud.

FAQs

Q1: What makes precision CNC machining ideal for custom aluminum parts?

A: Precision CNC machining dishes out laser accuracy, bulletproof repeatability, and scale that flexes easy to demand. Complex details carve out flawless. Runs maintain elite standards run after run.

Q2: Why choose aluminum alloys like the 6061, 6063, and T5 series for fabricating battery enclosures?

A: Alloys such as 6061, 6063, and T5 strike that sweet spot of brawn, low mass, and rust defiance tailored for EV grit. They machine buttery and finish fierce to boot.

Q3: How does XiHui ensure quality control during the manufacturing process?

A: XiHui deploys iron-fisted checks across production beats with tech that spots flaws miles off. Teams of aces back it up strong. Standards tower high. Deliveries pack endurance built-in.