In the world of modern production, some tools are now vital. Precision CNC machining and Wire EDM are two of them. They are used for making very precise and detailed components. What’s more, these methods allow makers to build complicated parts that must fit perfectly. This is crucial for industries where top performance and safety are the main goals.

Importance of High-Precision Aluminum Parts in Automotive and Medical Industries

Very exact aluminum components are a key part of both the car and medical fields. In vehicles, for instance, these parts help make them lighter. This saves gas and makes them run better. In the world of medical tools, such precision is needed for other reasons. First of all, it makes sure the parts are safe for the body. It also ensures they work dependably and meet strict government rules.

Product designs are getting more complex all the time. So, there is a bigger need for production methods that can create parts with tricky shapes, great surface quality, and very exact measurements. Precision CNC machining and Wire EDM are the perfect answer to these new demands.

Precision CNC Machining: Capabilities and Benefits

Precision CNC machining uses tools run by computers. Their job is to cut away material from a block with amazing precision.

Definition and Core Processes of Precision CNC Machining

CNC machining, which stands for Computer Numerical Control, is all about the automatic control of cutting tools. These can be things like mills, lathes, and drills. This method allows for making parts that are the same every time. Thus, it’s great for creating just a few test versions or for making thousands of them.

Tolerances, Surface Finishes, and Material Versatility

A key feature of precision CNC machining is that it can work with very small margins of error. These are checked with special measuring tools like Coordinate Measuring Machines (CMM).

- Typical Tolerance Ranges for Aluminum Components: For aluminum pieces, the margin for error can be as small as ±0.005 mm. This depends on how big and complex the piece is. Such accuracy is vital in products where many different parts have to fit together perfectly.

- Surface Treatment Options for Enhanced Performance: There are many surface finishes that can be added to make a part work better and last longer. Anodizing is a common one. It helps stop rust and wear. There are different kinds, like Type II (standard) for looks and protection, and Type III (hardcoat) for jobs that need something tougher.

Advantages in Producing Complex Geometries

CNC machining is great at making parts with difficult shapes. For example, it can create tricky internal spaces, undercuts, or features on many sides that would be hard to make with old-fashioned methods. This makes it perfect for producing top-quality engine covers for cars or easy-to-hold handles for medical tools.

Wire EDM in High-Precision Manufacturing

Wire EDM works alongside CNC machining. It helps by making even more detailed features without putting any physical strain on the part.

What is Wire EDM and How It Works

Wire EDM uses a skinny, electric wire. The wire cuts through metals like aluminum using tiny sparks. Unlike normal cutting, the tool never touches the metal. This allows for very fine and exact cuts.

Key Benefits of Using Wire EDM for Aluminum Parts

- Achieving Intricate Cuts Without Mechanical Stress: No cutting force is used in the process. Because of this, very delicate pieces can be shaped without being bent or damaged. This is perfect for thin or fragile aluminum parts used in important jobs.

- Suitability for Heat-Sensitive Applications: Wire EDM creates a very small heat-affected zone (HAZ) when compared to older cutting styles. This makes it a great choice for work where keeping the part cool is important for its shape and strength.

Applications in Automotive and Medical Fields

In the car industry, Wire EDM is often used to make exact die inserts. It also helps create complex molds for casting light aluminum parts. In medicine, it allows for the making of surgical instruments and implants with tiny features needed for less invasive operations.

Aluminum as a Material Choice for Automotive and Medical Parts

Aluminum is still a favorite material. This is because it has a great mix of strength, lightness, and ease of use.

Characteristics That Make Aluminum Ideal for Precision Machining

- Corrosion Resistance and Lightweight Strength: Aluminum naturally forms a protective layer against rust. It also gives a lot of strength for very little weight. These are huge benefits for both fuel-saving cars and medical implants.

- Excellent Thermal Conductivity and Biocompatibility: The material is great at moving heat. This makes it useful for heat sinks in cars full of electronics or in medical testing gear. Some aluminum types are also very safe for use in the human body, such as in artificial limbs or surgical tools.

Commonly Used Aluminum Grades in CNC & EDM Processes

Choosing the right type of aluminum is key to how the part will work. Common types include 6061, which is strong and easy to work with. 6063 is used for its great surface quality and rust protection, and 5050 is good for its workability and use near saltwater.

Applications in the Automotive & Medical Sectors

Automotive Sector

Car engineering needs high-quality parts that can handle tough situations.

- Examples of Complex Automotive Components: Parts like engine blocks, transmission boxes, and suspension pieces need to be made perfectly. This ensures they seal correctly, weigh less, and stay in line under pressure. All of this can be done with precision CNC and Wire EDM.

- Enhancing Vehicle Performance: Manufacturers can swap heavier steel parts for precisely made aluminum ones. This lowers the car’s total weight. What follows is better speed, gas mileage, and handling.

Medical Sector

Making medical devices demands total accuracy and cleanliness. This is to meet tough rules for patient safety.

- Examples of Medical Devices: CNC machining is used to make comfortable surgical tools, artificial limbs, and strong cases for medical equipment. These parts are great because they are light, strong, and simple to clean.

- Importance of Tolerances and Surface Finishes: Exact measurements stop problems during an operation. Besides that, a smooth and clean surface prevents germs from sticking. This is a huge deal for keeping things sterile.

Integration with Other Manufacturing Techniques

To offer a full package, precision CNC machining is often combined with other steps in one production line.

- Combining Operations: Modern machining centers can switch between milling, turning, drilling, and grinding without a pause. This all-in-one method makes finished parts better and faster.

- Post-Machining Processes: Extra steps are offered to meet special needs. These include smoothing sharp edges for medical tool safety, anodizing for rust protection, and powder coating or painting for looks. Many custom colors and finishes are available.

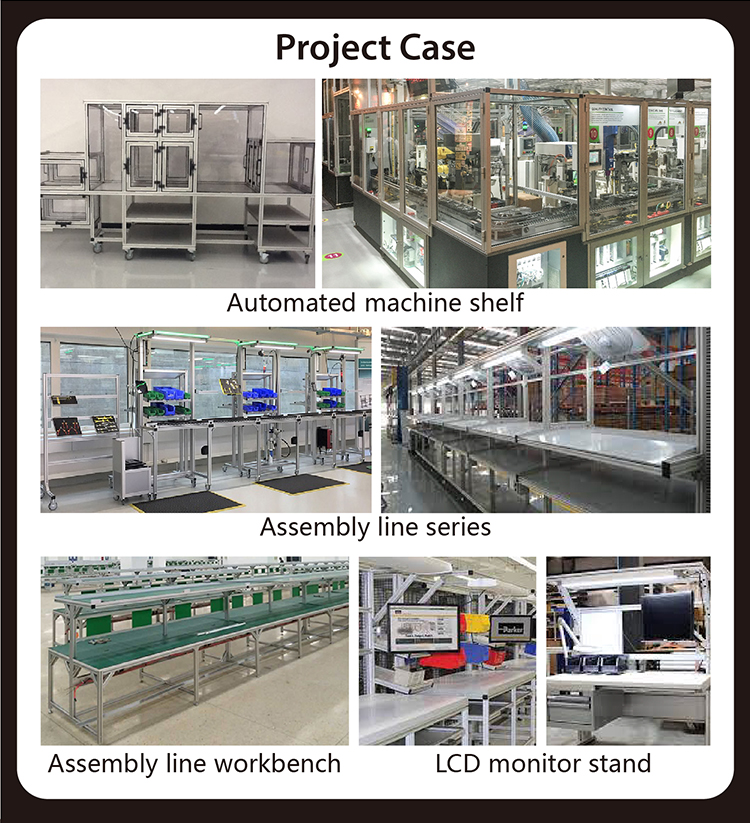

XiHui Aluminium: Your Trusted Partner for Custom Aluminum Components

XiHui Aluminium is a top provider of high-grade, custom aluminum parts. We use advanced production methods like precision CNC machining and Wire EDM.

- Company Background and Expertise: We have over 30 years of experience in making quality products. We also offer a huge library of over 10,000 existing molds. This can greatly speed up development time and lower tooling expenses for our customers.

- Advanced Manufacturing Capabilities: Our plant has 15 extrusion lines and more than 40 deep-processing machines. Also, our quality system is certified to ISO 9001, so every part is guaranteed to meet high standards.

- Full-Service Solutions from Design to Delivery: Our extra services include help from assembly engineers. They can give detailed assembly plans and better solutions if you ask. We offer complete OEM/ODM services made to fit the needs of our clients around the world.

FAQs

Q1: What aluminum grades are best suited for precision CNC machining?

A: The right grade really depends on the job. For example, 6061-T6 is a wonderful all-around option due to its great strength for its weight and how easy it is to machine. 6063 is better for parts that need a top-quality surface for anodizing. If you need even more strength, 7075 is often used, but it’s harder to work with.

Q2: Can XiHui Aluminium handle both prototyping and mass production?

A: Yes. Our setup is made to handle the whole life of a product. We help with quick prototyping to check designs. Then, we can easily switch to making large numbers of parts using our many extrusion lines and automatic machines.

Q3: What is the typical lead time for custom aluminum parts?

A: The time frame changes based on how complex the project is. Parts from materials we have in stock can often be sent in 3-5 days. For custom jobs that need a new mold, it takes another 7-15 days for the tooling. Big production orders are usually finished in 25-30 days.