Modern architecture is always pushing the limits of design and structural creativity. Because of this, the need for precisely cut aluminum parts has grown a lot. From the outside of skyscrapers to modular framing systems, architects and engineers need parts that are both strong and look good. This is where CNC plasma cutting really changes the game.

CNC plasma cutting is a huge part of today’s manufacturing world. It offers amazing precision, speed, and flexibility. What’s more, it allows for the making of custom plasma cutting solutions made just for building needs, especially for big aluminum gussets and brackets.

Fundamentals of CNC Plasma Cutting for Aluminum

First of all, CNC (Computer Numerical Control) plasma cutting is a process. It uses a jet of ionized gas to melt and cut through materials that conduct electricity, like aluminum. When used on aluminum alloys, this method gives you clean cuts and doesn’t bend the material much.

CNC plasma cutting has some clear benefits when you compare it to older ways of cutting by hand or machine.

How CNC Plasma Cutting Works with Aluminum Alloys

The whole thing starts with a very fast jet of ionized gas. This jet carries electricity from the torch to the metal part. This powerful arc melts the aluminum. At the same time, the gas blows the melted metal away, leaving a very exact cut. A computer controls the system using CAD/CAM files, so every part can be made exactly the same, over and over again.

Advantages of CNC Plasma Cutting Over Traditional Methods

- Speed and Efficiency: CNC plasma cutters are incredibly fast. They work especially quickly on thinner aluminum sheets, which cuts down on production time a great deal. This makes them perfect for construction projects that have tight deadlines.

- Accuracy and Repeatability: These machines are run by digital controls and automatic motion systems. Because of this, they can make identical parts with very small differences. This is vital when making structural gussets or brackets for a building’s exterior.

- Compatibility with Large-Format Materials: Plasma tables are big. They can handle large sheets of aluminum that are several meters long and wide. So, they are well-suited for architectural-sized parts like wall panels or support structures.

Key Applications in Architectural Frameworks

The flexibility of custom plasma cutting means it can be used for many architectural parts where both strength and looks are important.

Structural Gussets for Load-Bearing Frames

Gussets are super important for making joints in load-bearing frames stronger. CNC plasma cutting lets designers make gussets that are perfectly shaped for specific stress points. This improves structural strength without wasting material.

Custom Brackets for Façade and Support Systems

A building’s facade often needs special brackets. These brackets have to handle functional loads and also match the visual design. Plasma-cut brackets can have complex shapes or even logos cut into them without losing any strength.

Integration with Modular Aluminum Profiles

Modular systems often use standard profiles like Aluminum T-Slot Profiles. These profiles are commonly used with custom-cut connectors or plates made with CNC plasma. This allows for quick assembly in structures like partition walls or automation enclosures.

Material Considerations for Large-Format Components

When you’re using aluminum for architectural jobs, it’s really important to understand the material’s properties. This helps make sure the final product comes out right.

Commonly Used Aluminum Grades (6061, 6063, 7075)

Aluminum grades like 6061 and 6063 are very popular. This is because they resist rust and are easy to work with. For example, 6061 has a great strength-to-weight ratio. On the other hand, 6063 is often chosen because it has a better surface finish after anodizing.

Thickness Tolerances and Flatness Requirements

Large parts have to be very flat to make sure they fit correctly during installation. CNC plasma systems have tools like floating heads or height sensors. These tools help keep the cuts consistent, even on sheets that are a bit bent.

Surface Finish Options After Plasma Cutting

After cutting, there are options like anodizing or powder coating. These treatments make the parts look better and last longer. A lot of custom colors are available through these processes, and you can even get wood grain finishes. This lets architects perfectly match finishes across different parts of a building.

Design Optimization for CNC Plasma Cut Parts

To get the most out of CNC plasma technology in custom projects, you need to plan carefully in the design stage.

Best Practices in CAD/CAM File Preparation

Your files should be vector-based, like a DXF file. They need to have clear paths and account for the width of the cut. Also, try to avoid overlapping lines or open shapes, because these can mess up the cutter’s path.

Minimizing Warping and Heat Distortion During Cutting

You can reduce heat distortion. One way is to space the cuts out in a smart way. Another way is to use water tables, which soak up extra heat while the machine is running. This is especially important for thin aluminum sheets being cut at high power.

Hole Placement, Edge Geometry, and Mounting Features

Try not to put holes too close to the edges. This can cause cracks during installation. Using rounded inner corners helps lower stress points. In addition, angled edges make the parts fit better with other pieces, like architectural frame profiles, enclosure profiles, and equipment beam profiles you often see in building assemblies.

Benefits of Custom Plasma Cutting in Construction Projects

Using rapid CNC plasma cutting in construction brings a few key advantages:

- Faster Project Turnaround Times with On-Demand Fabrication: Custom parts can be made in just hours instead of days using digital files. This makes it possible to create prototypes faster or get emergency replacements on-site if needed.

- Reduced Waste Through Precision Nesting Techniques: Smart nesting software arranges parts on the raw sheets very efficiently. Thus, it cuts down on scrap material and gets the most out of every aluminum plate.

- Enhanced Aesthetic Appeal with Clean Edge Finishes: Modern plasma cutters create smooth edges that don’t need much finishing work. This is great when the parts will be seen in the final design, like in exposed trusses or decorative screens.

XiHui Aluminium: Your Partner in Custom Aluminum Solutions

For architects who need a dependable partner to deliver precision-made parts on a large scale, XiHui Aluminium offers a full range of services that meet industry demands.

Overview of XiHui Aluminium’s Capabilities and Services

Our factory has been in the business for 33 years. We have a library of over 10,000 sets of molds for a huge variety of designs. We can also create custom molds for our customers. This deep experience guarantees that clients get personalized solutions supported by a strong manufacturing system.

OEM CNC Machining and Metal Turning Services

XiHui offers OEM machining services for architectural-grade aluminum alloys. This includes turning operations needed for round connectors or standoff mounts used in curtain wall systems.

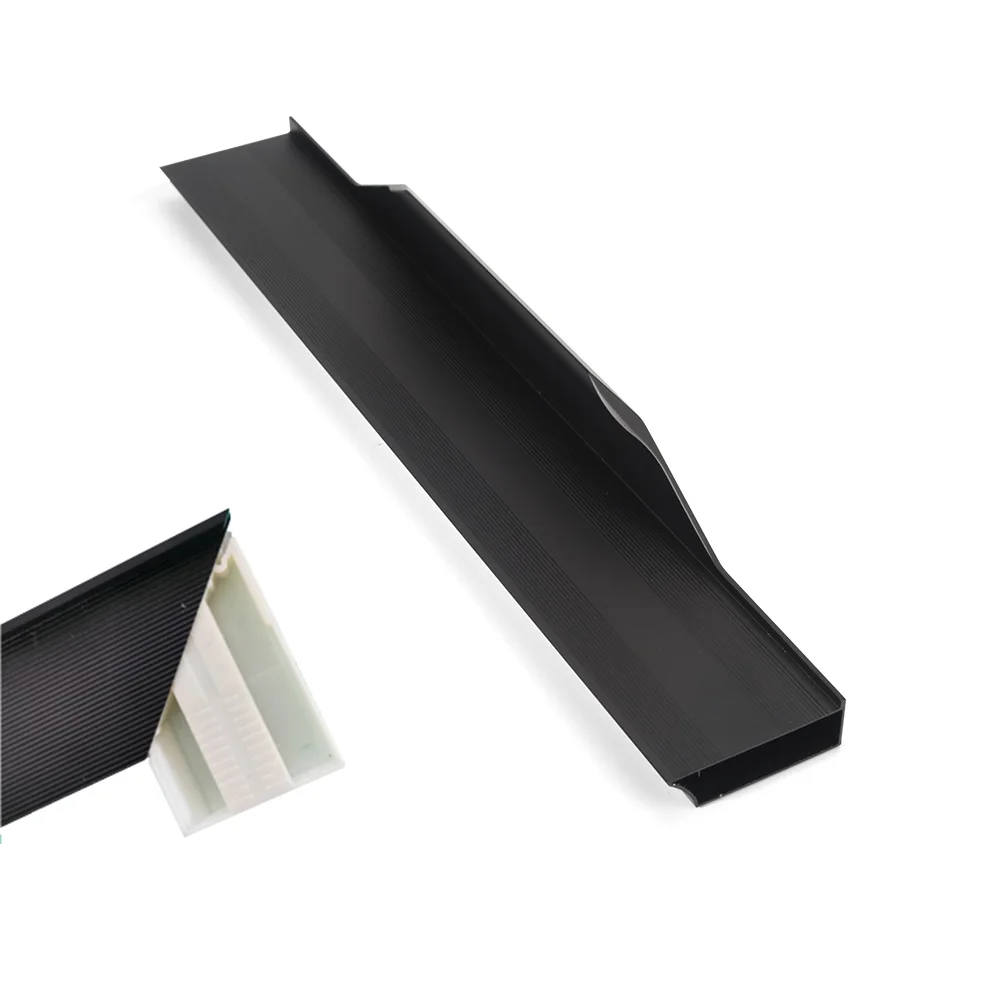

Advanced Surface Treatments: Anodizing, Powder Coating, Polishing

Stock colors include anodized silver-white and anodized black. These finishes provide protection from rust and fit well with modern design looks in all kinds of buildings, from homes to business centers.

In-House Engineering Support and ISO-Certified Processes

Their engineering team helps clients from the idea phase all the way to the final product. They use ISO-certified methods, which ensures top quality throughout every step of the project.

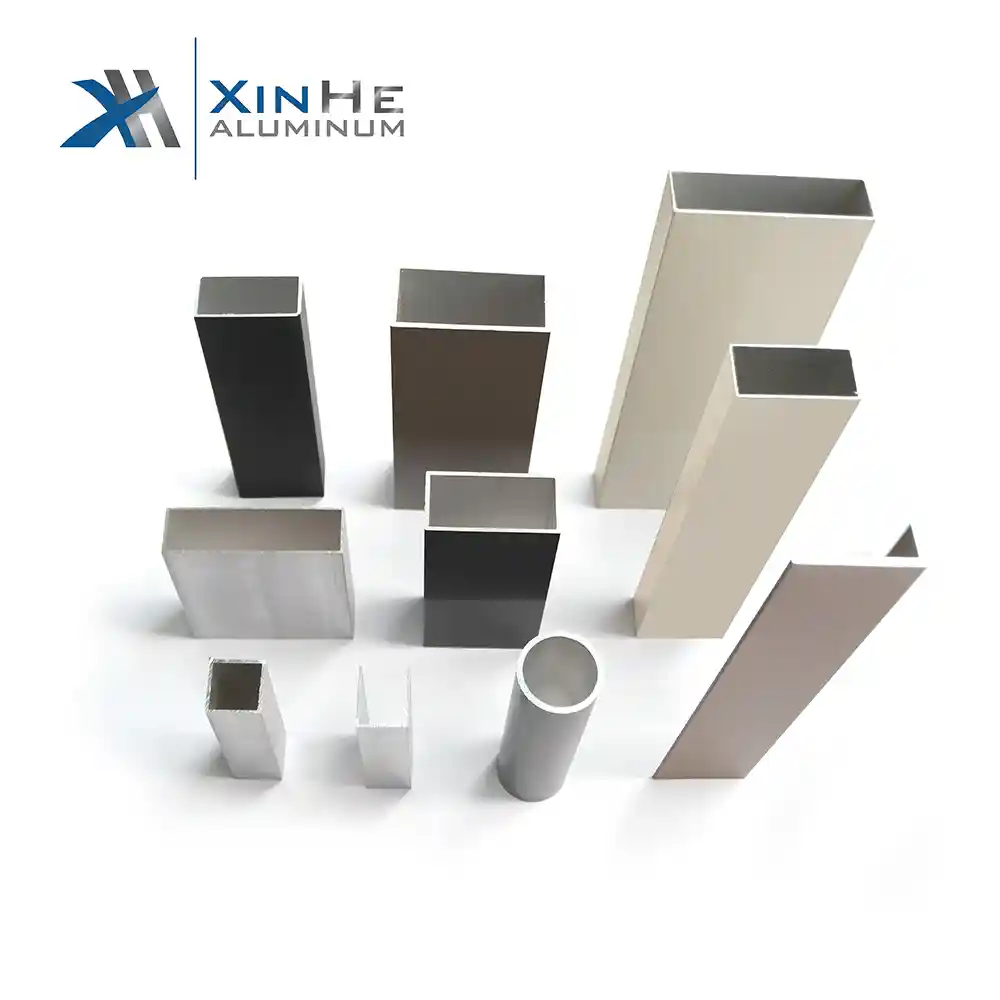

Product Range Tailored to Architectural Needs

XiHui’s catalog has T-Slot Profiles, Structural Tubes, and Window & Door Frames. Aluminum industrial profiles are available right off the shelf or can be customized from drawings. This offers a lot of flexibility for different construction uses, including framing systems and facade supports.

FAQs:

Q1: What thicknesses of aluminum can be cut using CNC plasma cutting?

A: Most CNC plasma systems can cut aluminum from 1mm up to 50mm thick, but it depends on the machine’s power. For architectural parts like gussets or brackets, the thickness is usually between 3mm and 12mm. This provides a good mix of strength and low weight.

Q2: Is CNC plasma cutting suitable for decorative architectural features?

A: Yes! It’s perfect for that. It can cut complex patterns cleanly on big sheets. So, custom plasma cutting is ideal for decorative panels, perforated screens, sign backings, and other visible pieces that need to be both functional and beautiful.

Q3: Can XiHui Aluminium assist in designing custom-cut components?

A: Of course. Our team has assembly engineers who can give you assembly drawings and solutions based on what you need. Their engineering support makes sure your designs are set up not just for manufacturing, but also for easy assembly on the job site.