In the modern era dominated by technological advancements, carefully crafted aluminum parts form the backbone of vital industries focused on high performance, including aerospace, automotive, robotics, and electronics. Custom CNC machining speeds up the process of developing products by offering production whenever it’s needed. Moreover, it allows for scaling up to large quantities while keeping the allowed variations very small and steady.

Overview of Aluminum Extrusion in Precision Manufacturing

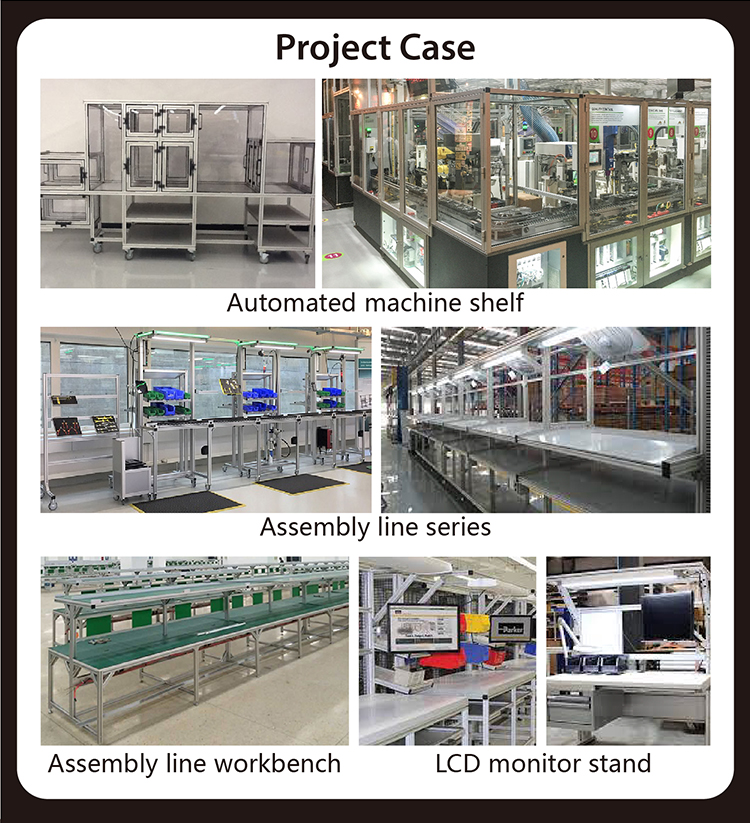

Aluminum extrusion starts by warming a block of material called a billet and then pushing it through a die molded into a particular shape, which creates outlines with even sections all the way along. Aluminum Industrial Profile, Industrial aluminum extrusions, industrial aluminum alloy profiles, industrial aluminum profiles are alloy materials primarily composed of aluminum, formed by hot melting and extruding aluminum billets to obtain aluminum materials with different cross-sectional shapes.

This technique suits well for making long stretches of detailed outlines, such as frames with T-slots, rails for housings, or fins for heat sinks in LEDs. Plus, extrusion handles many kinds of forms—like squares, rounds, or angled ones—and keeps things very uniform, no matter how many batches you run. As a result, it becomes a go-to method for projects needing consistent pieces over extended production, blending efficiency with the flexibility to match diverse design requirements seamlessly.

What Benefits Does Extrusion Offer for Precision Applications?

Aluminum profiles from extrusion shine in situations that call for keeping weight low and producing lots of items without high expenses. Our extruded aluminum heat sinks are built to manage heat very well, fitting perfectly for strong LED lights and similar tough tasks. After extrusion, CNC machining can make the fits even tighter or include extras like grooves, holes with threads, or spots for mounting. These additions enhance how the parts fit into larger assemblies, providing versatility that meets the demands of modern engineering challenges.

Profiles such as the Anodized Industrial CNC Extrusion Aluminum Profile give great steadiness in size and good conduction of heat, which makes them a strong match for gear in automation, boxes for electronics, or pieces in renewable energy setups.

Are There Limitations When Using Extruded Aluminum in High-Stress Environments?

Yes, there are some drawbacks. Extrusions do a good job with steady pressures and twisting forces, but they don’t handle moving parts or heavy, sudden hits as effectively. Overall, their toughness tends to be less than that of forged items because they lack the finer inner buildup that comes from being pressed hard.

Characteristics of Forged Aluminum Components

Forging requires heating up aluminum billets and then using pressing power with dies that are either open or closed to shape parts that have tightly packed inner structures. The closed-die style often gets picked for making many identical shapes in large quantities. Through this whole step, the parts end up with an improved flow of inner grains that follow the lines where stress will hit, which boosts how much load they can take. Consequently, this results in components that offer dependable performance in roles requiring sustained strength, making the process a staple in industries valuing long-term reliability over quick adaptations.

What Mechanical Advantages Do Forged Parts Provide?

The main plus of forged aluminum lies in its better pull strength and ability to resist tiring out from repeated stress. Parts made this way show outstanding defense against shocks and solid build trust, all thanks to their even inner structure in all directions. These traits make forged blanks a great fit for uses in actuators for aerospace, links in automotive suspension, and equipment for competitive motorsports. In these high-stakes areas, the enhanced qualities directly translate to safer operations and extended service life, underscoring why forging remains a preferred choice for critical components.

What Are the Design Trade-Offs with Forging?

Though forging brings top-notch mechanical benefits, it doesn’t do as well at creating complicated empty insides in shapes. It also resists changes to plans easily, given the high cost of dies and the longer waits to get started, particularly not worth it for small runs or cycles of testing new models over and over. These factors push designers to weigh the gains against the hurdles, often leading to hybrid approaches where forging pairs with other methods to balance strength with practicality in evolving projects.

Comparative Analysis: Extrusion vs Forging in Precision Contexts

Forged parts clearly take the lead in toughness measures, suiting them well for jobs where safety is key. By comparison, extrusions provide a smarter use of weight and are chosen when room to adjust designs and saving materials matter more than the highest possible strength. This difference guides selections based on project needs, allowing teams to pick what aligns best with goals like cost control or performance peaks.

How Do Tolerances and Surface Finishes Compare?

Both ways gain from extra work done by the CNC after the main shaping. That being said, profiles from extrusion let you control straight-line allowances and even surfaces over far longer lengths more exactly, and at less expense. Forged parts might need broader cutting to get the same smooth results. Understanding this helps in planning the full workflow, ensuring the final touches meet standards without unnecessary steps.

What About Material Waste and Efficiency?

Extrusion works as a process close to the end shape, cutting down on waste by matching what comes out to the needed form closely. Specializing in the production of aluminum extruded profiles, good at manufacturing ultra-thin materials. Forging usually calls for more cutting away or shaping to get rid of extra bits like rough overflows or surplus stock.

Role of CNC Machining in Enhancing Custom Aluminum Parts

No matter if you begin with a rail from extrusion or a basic from forging, CNC machining provides the last touches—as holes threaded for screws, slots cut exactly, or spots for connecting—all crucial for putting things together and making them work as one unit. This step ties the initial forming to the final use, creating parts that integrate smoothly into complex systems with minimal adjustments.

What Customization Capabilities Does CNC Machining Offer?

Turning (Lathe Operations)

Very precise round features, such as bushings or spacers, are made using lathes with multiple axes, delivering the exactness needed for tight fits in assemblies.

Milling (3-axis/5-axis)

Milling allows for forming curves on several sides at once—a necessity for supports or covers that have different levels of thickness, enabling intricate designs that enhance functionality.

Drilling & Tapping

Exact holes or thread sizes get added based on the plans for assembly, done with stations that drill on their own for speed and accuracy.

EDM & Wire Cutting

For tricky spots like inner hollows or unusual shapes, electrical discharge machining (EDM) makes sure details are sharp down to tiny measurements, unlocking possibilities for advanced engineering feats.

Surface Treatment Options for CNC-Machined Aluminum Parts

- Anodizing: Boosts resistance to corrosion, with choices for clear or colored outer layers to suit different needs.

- Sandblasting / Bead Blasting: Gives a dull finish while clearing small rough edges, improving both look and feel.

- Powder Coating & Painting: Strengthens against sun rays and adds visual interest through strong guard coats.

- These options often get mixed according to common practices in the trade—for instance, anodized layers on heat sinks for LEDs to protect better, or powder-coated frames for automation setups to combine toughness with style. Such combinations allow for parts that serve dual purposes, enhancing both protection and presentation in professional environments.

Application Scenarios Across Industries

Aerospace: Light supports or housings for flight electronics, specified with close allowance rules to ensure safe flights. Automotive: Key building parts like arms for suspension or connectors for roll cages, built to handle road stresses. Electronics & Telecom: Parts that let out heat, aluminum extrusion heat sinks, with milled spots for circuit boards, keeping devices cool and operational.

Highlighting XiHui Aluminium’s Capabilities as a Manufacturer

XiHui Aluminium Co., Ltd., located in Foshan City, specializes in aluminum extrusion profiles and is good at producing ultra-thin profiles. With over 30 years of expertise and 40+ advanced CNC machines—including 5-axis centers—their workshop delivers ±0.01 mm precision across batch sizes from 50 pcs to large-scale runs. This blend of history and tech positions them to handle diverse orders, from simple to complex, with a focus on quality that builds client loyalty over time.

Their integrated services include drawing analysis, rapid prototyping, tight tolerance machining, surface treatments (anodizing, powder coating), and in-house CMM inspection.

Customer Support Approach at XiHui Aluminium

From fast DFM-based quotes to after-sales technical guidance, XiHui ensures a seamless procurement journey. Efficient DFM reviews followed by quick prototyping cycles shorten time-to-market. Their after-sales framework includes warranty coverage and traceable QC documentation to support clients long after delivery. This end-to-end care means partners receive ongoing help, turning potential challenges into opportunities for improvement and strengthening ties through reliable, responsive service.

Remarks on Choosing the Right Aluminum Processing Method

Choosing between extrusion and forging hinges on performance criteria—strength vs flexibility—and volume considerations. CNC finishing bridges both processes by converting raw shapes into precision-functioning components tailored to specific industries.

FAQ

Q1: What’s your minimum order quantity for custom CNC aluminum parts?

A1: Minimum order quantity is typically 500kg per design. However, small-batch prototyping can begin from 50 pieces per item, depending on complexity.

Q2: Which surface treatments do you offer for machined aluminum?

A2: We provide anodizing (clear/hard/colored), powder coating, sandblasting, polishing, brushing, and electrophoresis—customized per function or visual requirement.

Q3: How do you ensure quality consistency across large production runs?

A3: Quality assurance includes incoming material checks, real-time CMM monitoring during machining, ISO-standard final audits, and full traceability through our ERP system.