Computer Numerical Control (CNC) machining has transformed the aluminum industry. It allows manufacturers to craft custom aluminum parts with great accuracy and speed. Industries now need complex, exact components. CNC machining makes this possible. It turns raw aluminum extrusions into high-quality, purpose-built parts.

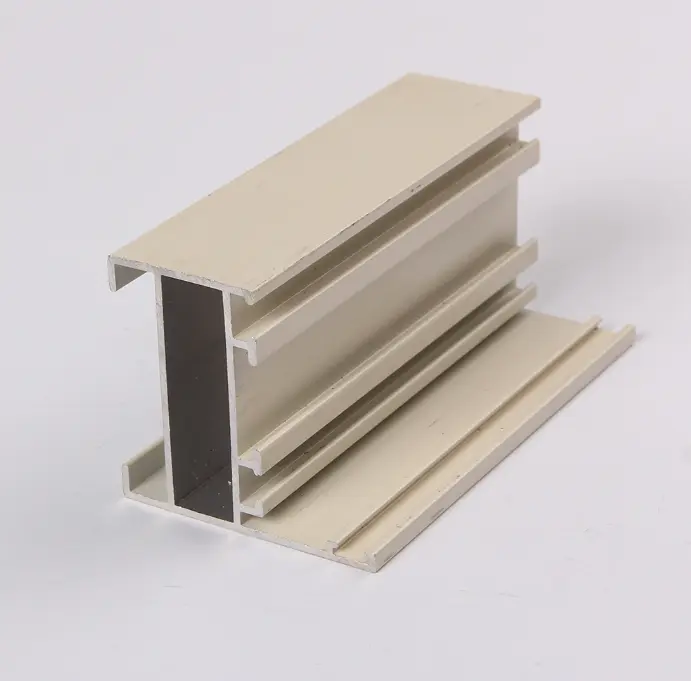

Accuracy is vital in making custom aluminum parts. A tiny mistake can ruin performance or safety in fields like aerospace or automation. CNC machining ensures every part meets strict standards. It delivers steady quality, even for large batches. Custom aluminum parts are used in many areas, like cars, electronics, building, and factory automation. An aluminum profile is an alloy material, mostly aluminum. The process starts with a hot extrusion method. This shapes the aluminum into various forms. The alloy mix decides the part’s strength and use.

About Xihui Aluminium

Xihui Aluminium excels in aluminum extrusion and advanced processing. With 33 years of experience, the company has deep knowledge and strong facilities to meet varied customer needs. We’re skilled and ready.

Our collection of over 10,000 molds offers many profile options, like the 3030, 4040, 6060, and 100100 series, with standard T5 or T6 finishes. Besides, we can create custom molds for unique needs. Our services go beyond extrusion. We provide CNC cutting, punching, slotting, anodizing, powder coating, and full assembly help. What’s more, our skilled assembly team offers drawings and solutions tailored to each project. This ensures a custom fit for every job.

CNC Precision Cutting for Custom Aluminum Parts

To make custom aluminum parts with tight measurements and complex shapes, Xihui Aluminium uses top-notch CNC cutting tools.

High-speed spindle cutting is one method. It uses fast-spinning tools to slice aluminum cleanly. This keeps the surface smooth. We also use multi-axis machining, like 3-axis and 5-axis CNC centers. These let us shape complex profiles with many angles without moving the material. This cuts errors and boosts speed. CNC cutting is highly accurate. It’s reliable for making thousands of identical parts. While overall sizes meet industry norms, precise internal features, like hole placement, are key for assembly. Plus, CNC machining reduces waste by planning tool paths smartly. This saves money and supports eco-friendly practices.

Advanced Punching Processes in Aluminum Machining

Punching is crucial for adding holes and slots needed for fastening and function. It’s more than just cutting.

Xihui Aluminium uses mechanical and hydraulic punching systems. We pick the right one based on the job’s complexity and size. Mechanical systems work fast for repetitive tasks. Hydraulic presses, however, offer better control for thicker or tougher materials. Our skill in custom die design and large mold collection gives flexibility. We can handle many shapes and sizes. Well-punched holes keep parts strong by spreading stress evenly. They also ensure parts fit with fasteners during assembly.

Slotting Solutions for Modular and Structural Applications

Slotting is a key skill at Xihui Aluminium. It supports modular designs used in automation, frames, and enclosures.

T-slots are common. They let bolts and nuts slide into place anywhere along the profile. This suits adjustable setups, like workstations or conveyors. We also make keyed slots. These hold interlocking parts to stop twisting under pressure, vital for precise mechanical setups. Tight slotting ensures parts work smoothly with standard hardware. Thus, accuracy directly affects the final product’s success.

Integration with T-Slot Hardware Systems

T-slot extrusions are versatile. They work with many fastening accessories. This allows modular designs. Users can adjust structures without welding, saving costs and enabling reuse. This is perfect for machine guards, test setups, or storage frames.

Xihui Aluminium offers many compatible accessories, like T-nuts, bolts, joining plates, brackets, and end caps. We can also find special parts for unique needs.

Material Selection and Surface Treatments

Choosing the right material affects how well parts are machined and perform. We often use alloys like 6061 and 6063. They’re strong yet light, resist rust, and are easy to weld. Common profile series include 3030, 4040, 4545, 5050, 6060, 6061, and 6063, in T5 and T6 finishes.

We provide various surface treatments, like anodizing (silver, white, black), powder coating (many colors), and wood grain finishes. These options let customers customize their parts.

Quality Control Measures at Xihui Aluminium

Xihui ensures top quality with thorough checks. We use Coordinate Measuring Machines (CMMs) to spot tiny errors in size compared to CAD designs. Surface checks follow global standards for consistency. Our adherence to international certifications means our products meet worldwide demands.

Advantages of Partnering with Xihui Aluminium

Xihui offers complete solutions, from design advice to final delivery. This simplifies the supply chain for clients globally. Our flexible setup handles both small prototypes and large orders without delays or quality issues. What’s more, our helpful customer support, backed by skilled engineers, ensures clear communication at every step.

Conclusion

Xihui Aluminium shines in precise CNC cutting, advanced punching, and accurate slotting. We’re a top choice for custom aluminum parts in tough applications. Our strength lies in our technology, customization, and quick delivery. With decades of experience, we’re key partners in creating tomorrow’s smart solutions as demand for light, strong materials grows.

FAQs

Q1: What industries benefit most from custom aluminum parts?

A: Sectors like car manufacturing, factory automation, electronics, and consumer product design gain a lot. Aluminum’s strength, light weight, rust resistance, and easy machining make it ideal, especially with alloys like 6061 and 6063.

Q2: What is the minimum order quantity (MOQ) for custom extrusions?

A: The MOQ is 500kg per model. If an order includes several models and the total weight exceeds one ton, a single model of 500kg is fine. For models under 500kg, an extra machine fee applies.

Q3: How fast can I expect delivery after placing an order?

A: In-stock items ship in 3-5 days after order confirmation. Customized full container orders take about 25-30 days. If a new mold is needed, add 7-15 days for tooling.