At XiHui Aluminium, we know how vital good materials and careful work are for building projects. Our know-how in custom aluminum alloy processing gives special answers that match the unique needs of today’s building tasks. By using new CNC methods, we provide architects, builders, and workers with parts that are tough, pretty, and helpful. In this article, we talk about why aluminum alloy is so important in building, how CNC methods make it better, and why teaming up with us helps your project win.

The Importance of Aluminum Alloy in Construction

Aluminum alloys are a big part of today’s building world. You see them in tall buildings and small houses. These materials are changing how we plan and make buildings. People use them a lot because they can handle tough building needs while being kind to the planet and lasting a long time.

Key Properties of Aluminum Alloy for Building Uses

Aluminum alloys are loved for their special features, which make them great for building:

- Light but strong: Aluminum alloys mix strength and lightness well. They make buildings lighter without losing power.

- No rust: They fight off rust and wear naturally. This helps them last in bad weather, keeping them strong for years.

- Can be reused: Aluminum can be recycled fully. This fits with the building world’s push for green ways.

- Easy to shape: It bends easily into fancy designs. This is perfect for special building looks.

These qualities make aluminum alloys a top choice for projects that need both strength and beauty.

Benefits of Using Aluminum Alloy in Modern Building Projects

Aluminum alloys do more than just have good features. They bring real pluses to building work:

- Lasts long: Aluminum parts stand up to bad weather. This lowers fix-up costs over time.

- Saves energy: Aluminum reflects light well. It helps make buildings that use less power, like in curtain wall setups.

- Looks nice: With many styles, like shiny or colored coatings, aluminum makes buildings look better.

- Saves money: Lighter materials cut down on shipping and setup costs. This keeps project budgets low.

These perks help aluminum alloys make buildings both useful and good-looking.

The Role of CNC Processing in Custom Aluminum Alloy Solutions

To get the best out of aluminum alloys, careful work is a must. CNC (Computer Numerical Control) methods let us make custom parts with super accuracy. This makes sure every piece fits your project just right. This technology is a big deal for giving high-quality, special answers in building.

What is CNC Processing and How It Works

CNC processing uses machines run by computers to cut and shape materials exactly. At XiHui Aluminium, we use top-notch CNC tools to shape, drill, and finish aluminum alloy pieces into custom parts. It starts with a digital plan. That plan turns into orders for the CNC machine, giving steady, same results every time. This way is great for making tricky shapes needed in today’s building designs.

Advantages of CNC Processing for Aluminum Alloy

CNC methods bring clear wins when working with aluminum alloys. They’re the best pick for custom answers.

Precision and Accuracy in Custom Designs

CNC machines work with super tiny accuracy. They make sure every part fits exact rules. This is key for building work, where small mistakes can hurt strength or looks. For example, our CNC-machined aluminum profiles are built to fit perfectly into curtain walls and window frames. They match just right every time.

Efficiency and Cost-Effectiveness

CNC methods speed up making parts by doing repeat tasks automatically. This cuts work costs and wastes less material. So, we can deliver faster and charge less for our clients. This makes it a smart choice for big building jobs.

Tailor-Made Solutions for the Construction Industry

Every building job is one-of-a-kind, with its own needs for design, use, and strength. At XiHui Aluminium, we focus on making custom CNC-processed aluminum alloy parts that fit the special needs of the building world, from strong frames to nice-looking finishes.

Meeting Specific Project Needs with Custom CNC Processing

Our custom CNC skills let us make parts that match exact job needs. Whether you want special curtain wall shapes, window frames, or support beams, we team up with clients to get their goals. Our crew uses high-tech design tools to plan parts. Then, we use CNC methods to make them exact. This way, every piece fits smoothly into your project. It boosts both use and looks.

Uses of Custom Aluminum Alloy Parts in Construction

Custom aluminum alloy parts are key in many building uses. They bring both strength and style.

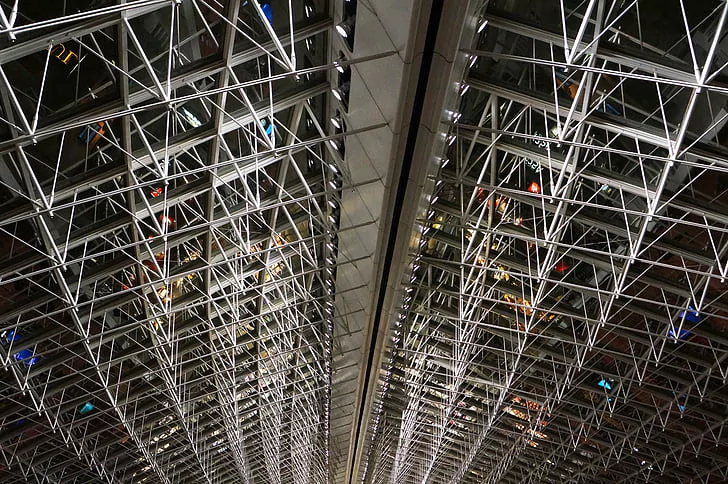

Structural Parts

Aluminum alloys are used a lot in structural pieces, like beams, columns, and supports. Their light weight eases stress on foundations. But their strength keeps buildings steady. Our extruded aluminum alloy profiles are made to handle the tough needs of tall buildings and big jobs.

Facade and Cladding Systems

Aluminum is a top pick for facade and cladding systems because it lasts and looks great. Our CNC-processed aluminum shapes let us make fancy facade designs. These improve a building’s outside while fighting weather and saving energy.

Decorative and Useful Elements

From railings to pretty panels, aluminum alloys give tons of ways to add style and use to building jobs. Our CNC methods make sure these pieces are made exactly, meeting both look and work needs.

Innovations in CNC Processing Technology for Aluminum Alloys

CNC processing keeps getting better. New tools make aluminum alloy parts higher quality and faster. At XiHui Aluminium, we stay on top of these changes to give our clients great answers.

Advances in Machines and Tools for Better Results

Today’s CNC machines have multi-angle moves. They let us make tricky shapes with better exactness. Fast parts and better cutting tools cut down making time but keep quality high. This helps us hit tight job deadlines without losing accuracy.

Use of Automation and Smart Technology

Automation is making CNC processing better by being more steady and cutting mistakes. Our smart CNC systems use live tracking and planned fixes. This keeps them working great with less downtime. It lets us deliver top-notch parts in big numbers, meeting the needs of large building jobs.

XiHui Aluminium: A Trusted Partner for Custom Aluminum Alloy Processing

At XiHui Aluminium, we’re proud to be a dependable partner for building experts worldwide. Our skill in custom aluminum alloy processing, plus our love for quality, makes us the right choice for your next job.

Overview of XiHui Aluminium’s Skills and Services

With lots of years in the field, we’re great at giving high-quality aluminum alloy answers for the building world. Our services include:

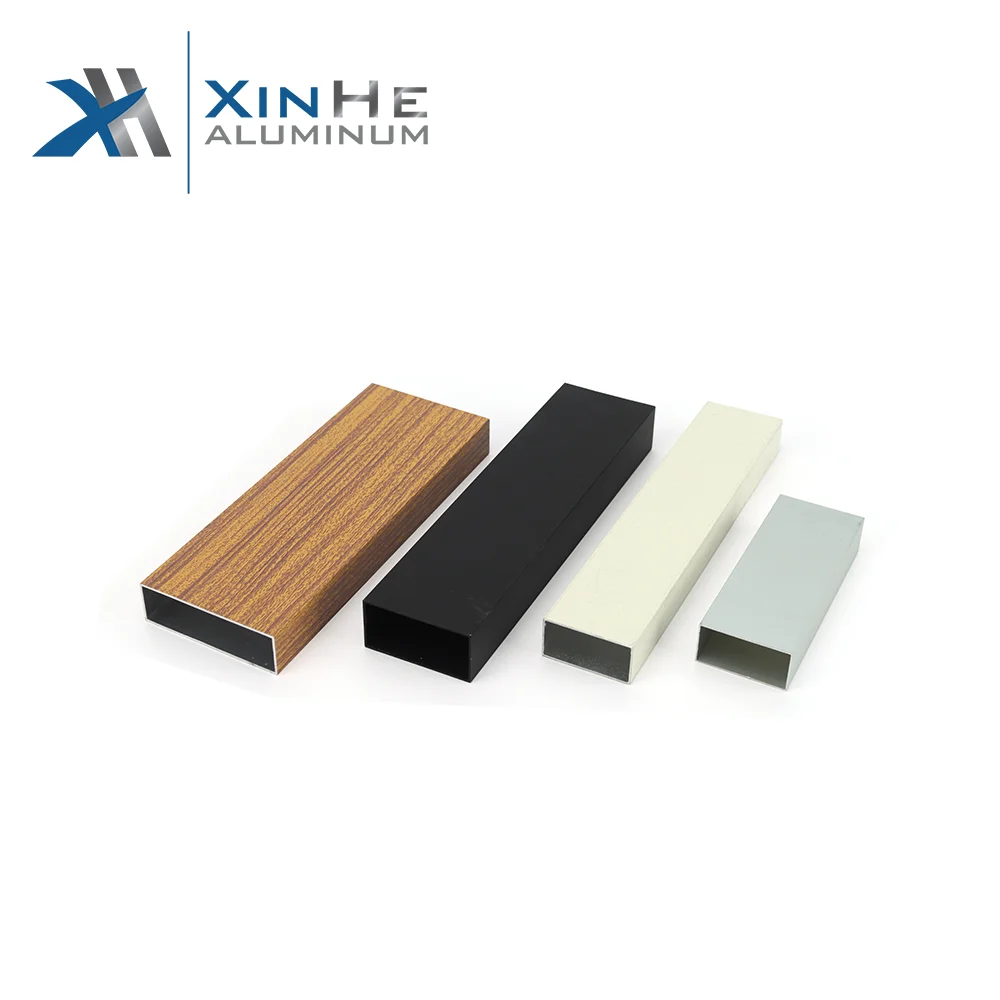

- Custom Shaping: We make aluminum shapes in all sizes and forms, including 6061 and 6063 alloys, to fit specific job needs.

- CNC Crafting: Our top CNC tools ensure exactness and sameness in every part.

- Surface Finishing: We give shiny coatings, colored layers, and other finishes to make parts stronger and prettier.

- Full Help: From design talks to delivery, we give complete support to make your job a success.

Contact us to talk about how we can turn your ideas into reality.

Why Choose XiHui Aluminium for Your Building Needs

Our love for quality, new ideas, and happy clients sets us apart:

- Know-how: Our team of skilled workers knows a lot about aluminum alloy processing.

- Quality Checks: We stick to tough rules to make sure every part meets building standards.

- Client-First: We work closely with clients to give answers that fit their job goals.

- Green Ways: Our reusable materials and smart methods help eco-friendly building.

Team up with us to raise your building jobs with carefully made aluminum parts.

Conclusion

Customized CNC processing of aluminum alloys gives great options, exactness, and speed for the building world. From strong frames to pretty facades, our answers at XiHui Aluminium help architects and builders make their dreams real. By mixing new CNC tools with our skill in aluminum alloy processing, we give special answers that fit the unique needs of today’s building jobs. Visit our homepage to check out our full services and start your next job with confidence.

FAQs on Customized CNC Processing of Aluminum Alloy

Q1 What are the main benefits of using aluminum alloy in building?

A1 Aluminum alloys bring big wins to building work. They’re light, so they ease stress on structures. They fight rust, staying strong in tough weather. They can be recycled, helping green building ways. Plus, their flexibility lets them work in many uses, from strong frames to pretty parts. They also make buildings look nice.

Q2 How does CNC processing ensure accuracy in custom designs?

A2 CNC processing makes sure of accuracy with computer-run tools that follow digital plans with super tiny exactness. This stops mistakes and gives steady results, even for fancy shapes. At XiHui Aluminium, our new CNC machines are set to meet exact rules, so every part fits your job’s needs perfectly.

Q3 Why should I choose XiHui Aluminium over other suppliers?

A3 XiHui Aluminium shines because of our skill in custom aluminum alloy processing, focus on quality, and care for clients. We give full answers, from design to delivery, using top CNC tools and green ways. Our team works closely with clients to deliver parts that meet specific job needs, ensuring both use and style are great.