The electronics industry is always changing quickly. In this fast-paced world, CNC precision manufacturing plays a key part. It is essential for making top-notch, custom parts for 3C digital accessories. These items cover computers, communication gadgets, and consumer electronics. All of them need parts with amazing accuracy and a great look to meet what users need and what the market expects.

In 3C digital accessories, having custom options and great quality is a must. People expect cool designs and strong performance. This applies to everything, from smartphone cases to laptop brackets and wearable device covers. So, manufacturers have to supply parts that not only fit perfectly but also help with cooling, structural strength, and the overall user experience.

There is a growing need for devices to be smaller, easier to carry, and able to do more things. This trend is pushing the demand for highly precise parts. Devices are becoming thinner and more complicated. CNC machining gives manufacturers a way to meet very strict rules while also being efficient and consistent.

CNC Machining Technology for 3C Digital Accessories

Modern electronics have complex needs. To meet these demands, CNC machining provides a range of abilities that older manufacturing methods just can’t offer.

Key Features of CNC Machining in Electronics Production

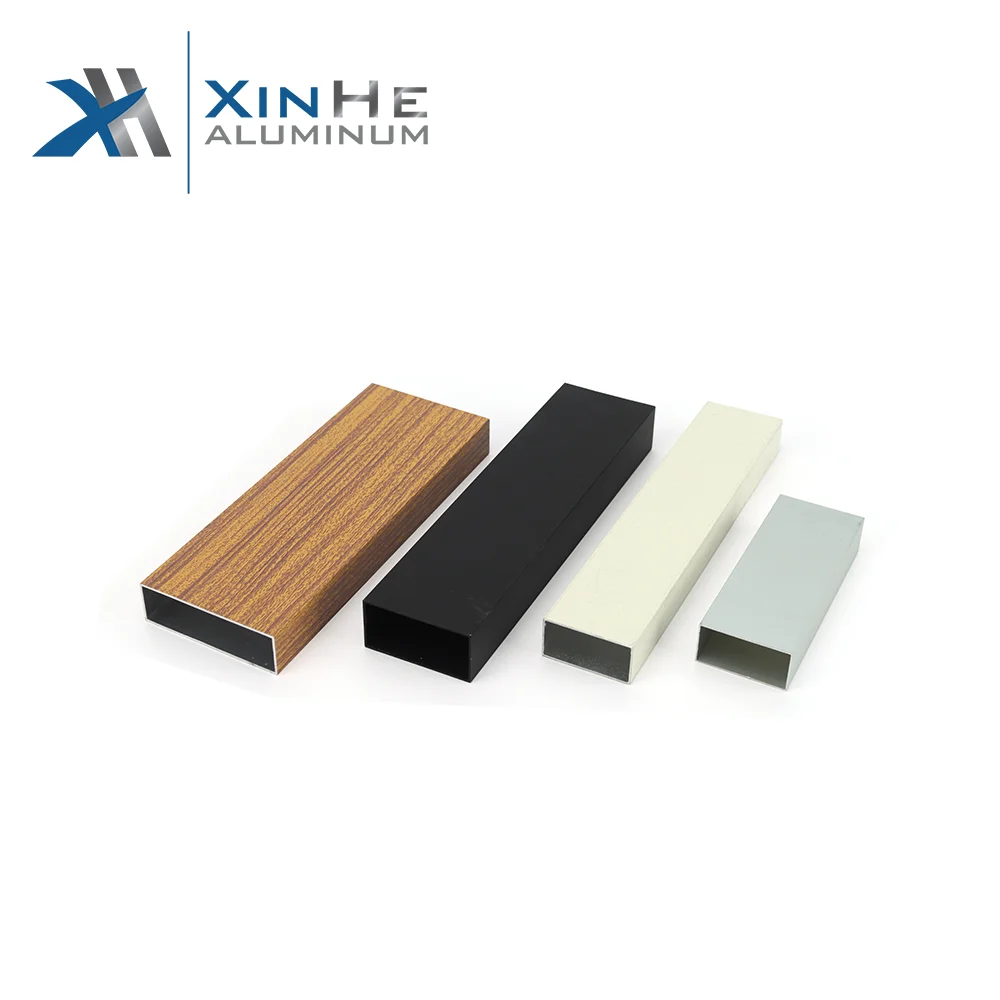

Industrial aluminum profiles are the starting point for many 3C parts. They are made by hot-melting and pushing aluminum alloy rods into different shapes. By carefully managing the alloy mix, various mechanical traits can be achieved. This flexibility makes aluminum a perfect material for the CNC methods used to make 3C accessories.

High Tolerance Capabilities and Repeatability

CNC machines can work with very tight tolerances, as close as ±0.01 mm. This makes sure every part fits exactly right inside small electronic gadgets. Besides, this repeatability guarantees that the quality is the same for large numbers of products. This is very important for mass-market 3C items like chargers or phone mounts.

Complex Geometry and Micro-Machining

Modern CNC machines can handle multi-axis machining. This allows for the creation of very detailed shapes. For example, they can make integrated cooling channels or curved cases with screw slots placed at just the right angles.

Materials Commonly Used in 3C Accessory Manufacturing

Choosing the right material is very important for performance and looks.

Aerospace-Grade Aluminum Alloys (6061, 7075, etc.)

A lot of common materials are used often, like alloys such as 3030, 4040, 6060, 6061, and 6063. This is because they have a great strength-to-weight ratio and resist rust well. For instance, alloys like 6061 are easy to machine but still very durable, which is great for devices you carry around.

Surface Finishing Options: Anodizing, Powder Coating, Polishing

Surface treatments make parts work better and look nicer. Common colors in stock like anodized silver and anodized black show how popular these finishes are. People like them for their stylish look and resistance to wear.

Benefits of CNC Precision Machining for 3C Products

Precision manufacturing has a few good points that directly affect product quality and how happy users are.

Enhanced Product Durability and Performance

High-precision machining allows for tight fits when assembling parts. This reduces spots of mechanical stress. The result is a product that lasts longer and can handle daily use without breaking down.

Lightweight Design for Portable Devices

Using aluminum alloys helps makers create frames that are light but also strong. This is a must for smartphones, tablets, and wearables, where every gram is important.

Superior Heat Dissipation and Structural Integrity

Aluminum is good at conducting heat. When combined with custom-designed heat sinks or vents, it helps cool down small devices like laptops or power adapters more effectively.

Application Scenarios in the 3C Industry

Precisely machined aluminum parts are a core component in many uses across the electronics field.

Smartphone and Tablet Housings

Today’s smartphones need very thin cases that are still strong. With CNC machining, the internal hole sizes of a profile become key to putting it all together. This ensures a perfect fit with circuits and makes assembly easier with correctly placed screw slots.

Laptop and Wearable Device Components

Laptops need strong yet light bezels, hinges, or brackets that can handle being opened and closed many times. Wearables use custom-milled frames that fit comfortably on the wrist while keeping sensors safe.

Accessories like Chargers, Stands, and Holders

Accessories often mix usefulness with style. Custom-made stands and holders are fully customizable in both size and color. This gives brands a special look through surface treatments like brushed finishes or powder coating.

Surface Treatment Techniques for Enhanced Functionality

Surface finishing is not just about looks. It also makes products last longer by protecting them from the environment.

Anodizing for Corrosion Resistance and Visual Appeal

Anodizing puts a protective oxide layer on aluminum surfaces. It comes in many colors. For example, anodized silver is used a lot in high-end electronic cases because of its modern style.

Sandblasting and Polishing for Texture Control

These methods are used to make surfaces smoother or to add matte textures. This can improve grip or make fingerprints less visible on handheld gadgets.

Powder Coating for Protective Finishes

Powder-coated white and powder-coated black are common choices. They offer bright colors and are also very tough against scratches or contact with chemicals during everyday use.

Manufacturing Process Flow from Design to Delivery

From the first idea to the final item, every step is set up for precision and speed.

From CAD Drawing to Prototype Development

First of all, engineers make detailed CAD models. These models then guide the machine programming. Prototypes are made quickly using materials already on hand, often from standard 3-meter lengths that can be cut to what clients need. This allows for fast design checks before starting mass production.

CNC Milling, Turning, Drilling, and Grinding Processes Explained

Milling is for shaping flat surfaces, while turning is for making round parts. Drilling adds accurate holes, and grinding makes sure surfaces are extra smooth. All these steps are done with tight tolerances using automatic CNC systems.

Quality Control Measures Across Each Stage

Every step includes checks. Tools like coordinate measuring machines (CMMs) are used to confirm that the sizes match the design plans. This makes sure every part meets high standards before it is sent out.

XiHui Aluminium: Expert Manufacturer of CNC Aluminum Profiles

XiHui Aluminium has more than 30 years of skill in precision aluminum processing. They specialize in industries like electronics accessories manufacturing.

Company Background and Industry Experience Since 1993

Our factory has 33 years of experience in making and selling products. We have a huge collection of tens of thousands of molds and many different design styles. This deep background means customers get proven solutions that are supported by technical expertise in many 3C uses.

Production Capabilities: Extrusion Lines, CNC Machines, Surface Treatment Facilities

XiHui has everything it needs under one roof. We operate complete facilities that include extrusion lines for making long profiles, advanced CNC machines for precise cutting and milling, and also lines for anodizing and powder coating. This setup ensures we can deliver quickly.

Commitment to R&D Innovation and Global OEM/ODM Services

We have strong R&D skills, helped by our large mold library. Because of this, we also offer custom mold development and production for our clients. XiHui provides custom OEM/ODM solutions that fit well with a client’s brand strategy in markets all over the world.

Why Choose XiHui Aluminium for Your 3C Component Needs

Picking the right supplier is very important. After all, product quality directly affects a brand’s name among tech-savvy shoppers everywhere.

ISO-Certified Quality Assurance Systems

XiHui closely follows international quality standards in everything it does. This guarantees that all batches have consistent quality, no matter how complex or large the order is.

Fast Turnaround Times with In-House Engineering Support

XiHui’s efficient team helps get products to market quickly without sacrificing quality. For example, standard items can be ready for shipment within 3-5 days of an order. Even fully custom designs, including mold development, are delivered within weeks.

Global Export Experience to Over 120 Countries

We started our business with strong logistics networks that serve clients on every continent. So, XiHui provides reliable delivery schedules. What’s more, our multilingual support teams are familiar with the international rules for consumer electronics markets worldwide.

FAQs:

Q1: What types of aluminum alloys are best suited for 3C digital accessories?

A: Alloys like 6061 and 7075 are picked often. This is because they are easy to machine, have a great strength-to-weight ratio, and resist rust. Thus, they are perfect choices for making durable yet light electronic cases or structural parts in portable devices.

Q2: Can I customize both dimensions and surface finish when ordering from XiHui Aluminium?

A: Yes. XiHui provides full customization. This includes profile sizes based on your CAD drawings and also surface treatments like anodizing (silver/black), powder coating (white/black), wood grain looks, and more. We support both practical needs and brand styles.

Q3: How long does it take from order placement to delivery?

A: Standard items that are in stock can be shipped in 3–5 days after the order is confirmed. Custom orders usually take 25–30 days, depending on the quantity. If a new mold needs to be developed, that might add another 7–15 days based on how complex it is.