CNC (Computer Numerical Control) aluminum machining is vital in today’s production world. It uses automated tools to shape aluminum parts with precision. The process delivers high accuracy and reliability. It excels at crafting intricate shapes and tailored components. Industries such as aerospace, automotive, electronics, and everyday products depend on it. This method ensures parts meet exact specifications.

The Importance of Design for Manufacturability (DFM) in Cost Reduction

Design for Manufacturability (DFM) focuses on creating simpler part designs. Its goal is to lower production costs while preserving quality. For CNC aluminum machining, DFM cuts down on wasted materials. It also reduces the time spent machining. As a result, it enhances efficiency across the process. Smart design choices yield substantial savings.

Common Applications of Custom CNC Aluminum Parts

Custom CNC machining creates aluminum cases, brackets, cooling fins, shells, and framework pieces. These parts are critical in sectors valuing lightweight strength and heat transfer. They play key roles in many applications. Their versatility makes them indispensable.

Key Factors Influencing CNC Aluminum Machining Costs

Knowing what affects costs helps engineers make wise choices early. This approach supports affordable production. Several factors drive expenses in CNC aluminum machining.

1. Material Selection and Its Impact on Cost

The aluminum alloy chosen impacts machining ease, part strength, and cost.

Comparison of 6061 vs. 6063 Aluminum Alloys

6061 aluminum boasts robust mechanical traits and resists corrosion well. It works for structural needs. On the other hand, 6063 provides a polished surface. It is ideal for decorative parts like cases or trim. Both alloys are cost-friendly. Yet, 6061 is easier to machine, which saves time.

Influence of Aluminum Grades on Machinability

Some aluminum alloys include elements like silicon or copper. These boost strength. However, they are tougher to machine. This wears tools faster. It also extends production time. Both issues increase costs significantly.

2. Part Design Considerations for Cost Efficiency

Thoughtful design reduces expenses. It simplifies the manufacturing process.

Wall Thickness and Tolerances

Keeping walls evenly thick prevents warping during machining. Very thin walls demand slower cuts. They also require extra passes. Likewise, overly tight tolerances raise costs. They offer no practical benefit unless essential.

Complexity and Geometry Constraints

Complex shapes, such as undercuts or deep hollows, need intricate toolpaths. These take longer to set up. Simplifying designs saves time. It also lowers expenses effectively.

Minimizing Setup Time Through Design Choices

Parts designed for fewer setups cut labor costs. They boost output too. Features aligned on shared axes help. Symmetrical shapes are another smart choice.

3. Machining Strategy and Tooling Optimization

Better machining methods save time. They also extend tool life.

Toolpath Planning and Cycle Time Reduction

Smart toolpath planning limits unnecessary moves. It speeds up material removal. High-speed machining (HSM) techniques cut production time. They preserve surface quality. This balance drives efficiency.

Tool Selection for Efficient Cutting

Picking the right tools, like coated carbide end mills for aluminum, improves results. These tools clear chips quickly. They also cut faster and last longer. Matching tool design to material traits enhances performance in CNC machining.

Surface Finishing Options for CNC Aluminum Parts

Finishing improves both the look and function of aluminum parts. It strengthens resistance to corrosion. It also enhances durability.

Anodizing: For Durability and a Premium Metallic Finish

Anodizing forms a strong, rust-proof layer on aluminum surfaces. This coating protects parts well.

Types of Anodizing

Type I (chromic acid) makes thin, protective layers, often for aerospace. Type II (sulfuric acid) suits decorative and durable finishes. Type III (“hardcoat”) creates the thickest, toughest layer. It is ideal for harsh settings.

Benefits

Anodizing keeps the metal’s natural glow. It resists rust and scratches effectively. Common colors include clear (silver), black, and champagne. These enhance both style and function.

Powder Coating: For Versatility and Robust Protection

Powder coating applies dry powder with an electric charge. Heat then forms a solid, polymer-based layer.

Process and Advantages

This technique creates a thick, smooth coating. It avoids drips or uneven spots. The finish withstands impacts better than wet paint. It offers many colors and textures. White and black coatings are widely chosen for their adaptability.

Sandblasting: For a Uniform Matte Finish

Sandblasting uses abrasive particles to texture surfaces. It creates a non-reflective, even look. Often, it prepares parts for anodizing or powder coating. This step improves coating adhesion and ensures a clean, matte appearance.

DFM Guidelines to Directly Reduce Machining Costs

- Simplify Shapes: Remove non-essential decorative features. This reduces machining effort.

- Fewer Setups: Design parts for machining from minimal angles. This saves time.

- Standard Features: Use common hole sizes and curves. This avoids special tools.

- Limit Tight Tolerances: Apply strict tolerances only where needed. This cuts unnecessary costs.

Selecting the Right CNC Machining Partner

A skilled manufacturer ensures project success. Choose one with strong production abilities. They should have reliable quality checks. Clear communication is also crucial.

Partners with integrated facilities offer benefits. These include extrusion, CNC machining, and finishing lines. Such setups maintain quality. They also shorten delivery times. Additionally, they lower costs for OEM/ODM projects.

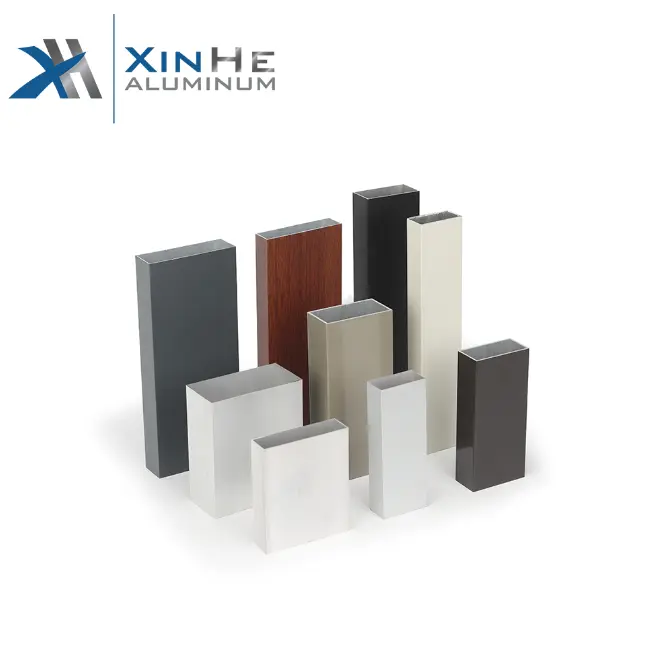

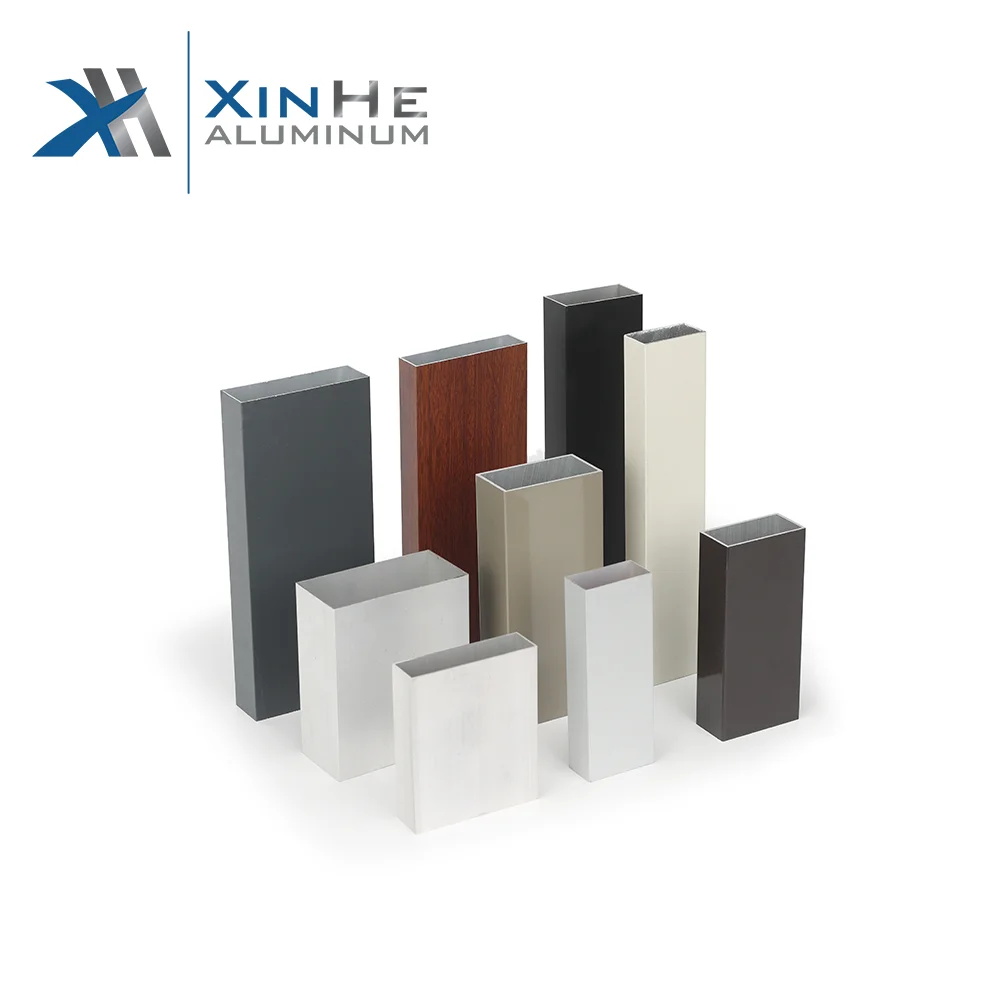

Introducing XiHui Aluminium: Your One-Stop Aluminum Manufacturing Partner

XiHui Aluminium (XHAlu) is a trusted choice for custom aluminum solutions. We handle your project from start to finish. This includes profile extrusion, precise CNC machining, surface finishing, and assembly.

Our modern facility has 15 extrusion lines and 40 CNC processing lines. We also have dedicated anodizing and powder coating lines. This setup manages large and complex projects efficiently. It ensures steady quality.

By uniting all processes in one place, we simplify management. We enforce strict quality control at every stage. Our dependable lead times support OEM and ODM partners effectively.

FAQs

Q1: What is the best surface finish for aluminum parts intended for outdoor use?

A: For outdoor use, Type III (hardcoat) anodizing and powder coating stand out. Type III offers strong hardness and UV resistance. Powder coating provides a thick, durable layer. It resists weathering and chipping. Your choice depends on appearance and environmental needs.

Q2: Can I request specific colors like black or white?

A: Yes. Anodizing and powder coating offer various shades. Powder coating provides a broad color range. Black and white are popular for their sleek, classic look.

Q3: How do I choose between anodizing and powder coating?

A: Opt for anodizing for a tough, scratch-resistant surface with a metallic look. Choose powder coating for more color choices and a thicker, impact-resistant layer. Your project’s needs guide the decision.