In today’s fast-paced manufacturing environment, OEM/ODM aluminum parts play a crucial role in delivering custom-engineered solutions for a wide range of industries. From automation systems to consumer electronics, these components offer high strength-to-weight ratios, corrosion resistance, and excellent machinability.

Precision engineering, especially through CNC milling and turning services, has become the backbone of modern aluminum parts production. These advanced techniques ensure that even the most complex geometries are manufactured with exceptional accuracy. Partnering with a specialized CNC service provider not only guarantees technical expertise but also streamlines the entire production cycle—from material selection to surface finishing—offering clients end-to-end manufacturing solutions.

Core Capabilities of CNC Milling and Turning Services

CNC machining services are vital for producing high-quality aluminum parts that meet demanding industry standards. Among these, CNC milling and turning stand out as foundational technologies.

CNC Milling for High-Precision Aluminum Components

CNC milling is ideal for creating intricate parts with tight tolerances. It utilizes rotating cutting tools to remove material from a workpiece, enabling the production of complex features like flat surfaces, slots, holes, and contours.

Key Features of CNC Milling Technology

CNC milling machines operate on multiple axes (from 3-axis to 5-axis), allowing for complex part geometries and superior repeatability. This capability is essential when manufacturing precision frames, enclosures, or structural components used in industrial equipment.

Tolerance Standards and Dimensional Accuracy

Modern CNC milling can achieve tolerances as tight as ±0.01mm. This level of precision is critical for components that must fit seamlessly into larger assemblies or perform reliably under mechanical stress.

Suitable Aluminum Alloys for Milling

Commonly milled alloys include 6061, 6063, and 7075 due to their excellent strength, corrosion resistance, and thermal properties, making them ideal for both structural and functional applications.

CNC Turning for Cylindrical and Complex Geometries

While milling is suited for prismatic parts, CNC turning excels at producing cylindrical components such as shafts, bushings, and threaded connectors.

How CNC Turning Enhances Production Efficiency

CNC turning uses a rotating workpiece against stationary cutting tools. This method allows for high-speed machining with minimal tool wear—ideal for mass production where consistency and speed are key.

Applications of Turned Aluminum Components

Turned parts are widely used in automotive systems, display mounts, and mechanical connectors where precise rotational profiles are required.

Integration with Other Machining Processes

CNC turning can be seamlessly integrated with secondary operations like drilling, tapping, or milling to produce fully finished parts in fewer setups, significantly reducing lead times.

Surface Finishing Techniques for Aluminum Parts

Surface treatments not only enhance the appearance of aluminum parts but also improve their durability and performance in various environments.

Anodizing and Its Functional Advantages

Anodizing is one of the most popular finishes for aluminum components due to its dual benefits of aesthetics and protection.

Corrosion Resistance and Aesthetic Enhancement

The anodizing process creates a hard, durable oxide layer on the surface of the aluminum, protecting it from corrosion and wear. This finish offers a sleek, metallic appearance suitable for visible assemblies.

Color Options and Thickness Control

Standard color options typically include clear (silver) and black anodizing. Custom colors can also be produced to meet specific customer requirements. The thickness of the anodized layer can be precisely controlled, with options for standard (Type II) or hardcoat (Type III) anodizing for applications requiring superior abrasion resistance.

Powder Coating and Sandblasting

These methods provide additional options for enhancing surface durability and achieving unique textures.

Durability and Texture Improvements

Powder coating applies a thick, uniform protective layer that is more durable than conventional paint. Sandblasting creates a clean, matte finish that can hide minor imperfections and improve paint or coating adhesion.

Environmental Considerations

Modern powder coating and anodizing are environmentally friendly processes with minimal VOC emissions when managed properly, making them suitable for sustainable manufacturing strategies.

Polishing, Mill Finish, and Custom Finishes

When aesthetics are a top priority, such as in consumer-facing products, additional finishing options are available.

Achieving Desired Reflectivity or Matte Appearance

Polishing can deliver a mirror-like, reflective finish, while a standard “mill finish” retains the raw, untextured look of the extruded aluminum. Custom textures can also be achieved through techniques like brushing or etching.

When to Choose Polishing

Polishing is preferred when visual appeal and reflectivity are prioritized over maximum corrosion resistance, such as in decorative displays or retail fixtures.

Material Selection for OEM/ODM Aluminum Parts

The choice of alloy directly affects performance characteristics such as strength, machinability, corrosion resistance, and cost-efficiency.

Commonly Used Aluminum Grades and Their Properties

Different aluminum alloys offer a unique balance of properties:

6061

- A versatile alloy known for its excellent strength, weldability, and corrosion resistance. It is a popular choice for structural applications.

6063

- Ideal for applications requiring a superior surface finish and good corrosion resistance. It is commonly used for architectural and decorative parts.

7075

- A high-strength, aerospace-grade alloy used for components subjected to high stress. It has lower weldability compared to the 6000 series.

Choosing the Right Alloy Based on Application Needs

Structural applications often benefit from 6061-T6 due to its robustness. Decorative parts frequently use 6063-T5 because it anodizes well. High-load-bearing parts in demanding environments may require 7075-T6 despite its higher cost.

Heat Treatment Options: T5 vs. T6 Tempering

Heat treatment, or tempering, enhances the mechanical properties of aluminum by altering its internal grain structure.

Impact on Mechanical Properties

The T6 temper provides higher tensile strength and hardness than the T5 temper but may slightly reduce ductility. The choice depends on the load conditions and formability requirements of the final application.

Applications Across Diverse Industries

OEM/ODM aluminum components are utilized across numerous sectors due to their adaptability and performance.

Automation and Industrial Equipment

Aluminum profiles, such as those from the 30x30mm or 40x40mm series, are widely used as frames for tables, cabinets, conveyor belts, and testing machinery in factory automation systems due to their modularity and light weight.

Automotive and Renewable Energy Sectors

Lightweight yet strong aluminum parts help reduce vehicle weight without compromising safety—a key factor in electric vehicle (EV) design. Similarly, solar panel frames benefit from corrosion-resistant extrusions.

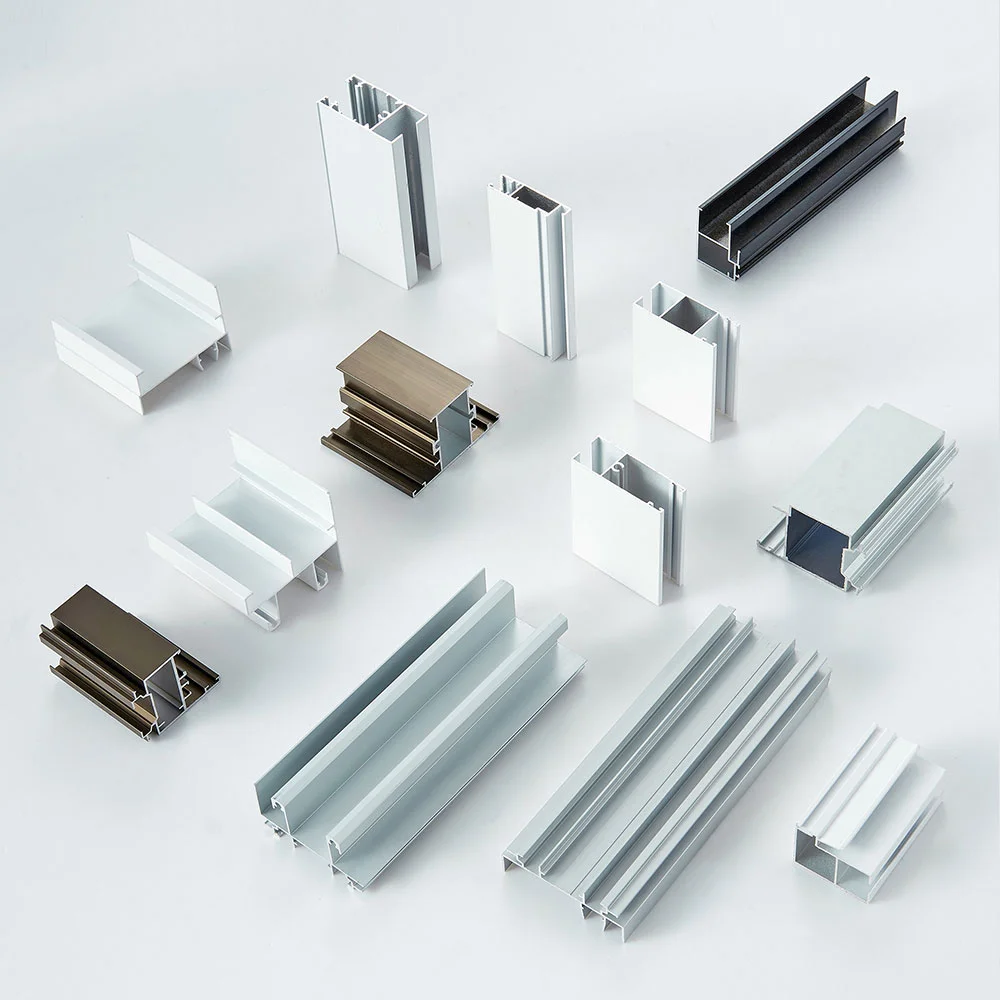

Consumer Electronics and Display Systems

Custom aluminum profiles are used to create elegant and durable enclosures, partitions, kiosks, and display stands that require both functional integrity and a premium aesthetic.

Manufacturing Precision: From Prototyping to Mass Production

Consistency from prototype validation through full-scale production is essential to ensuring product quality and performance.

Importance of Tight Tolerances

Maintaining dimensional accuracy ensures that components are interchangeable and fit correctly within complex assemblies—a necessity in automation and precision systems where misalignment could lead to operational failure.

Rapid Prototyping Capabilities

Quick turnaround is essential during the R&D phase. In-house engineering teams can expedite prototyping cycles by offering a quick feedback loop between design iterations and physical parts.

Packaging, Quality Control, and Global Logistics

Beyond production, ensuring safe delivery and maintaining quality standards across borders is a critical part of the service.

Protective Packaging Standards

Professional packaging methods, including protective plastic film and waterproof bundling, are used to protect products and maintain their integrity during shipping.

ISO 9001 Certification and Inspection Protocols

Quality assurance is maintained through a robust quality management system certified to ISO 9001. This includes in-process dimensional checks and final inspections, often using advanced equipment like Coordinate Measuring Machines (CMM), to ensure batch-to-batch consistency.

International Shipping Solutions

Experienced logistics support for global clients includes coordinating container loading plans based on order volume (e.g., 20GP containers for 9-10 tons, 40HQ containers for 19-21 tons).

Introduction to XiHui Aluminium as a Manufacturer

XiHui Aluminium brings over three decades of experience in extrusion-based manufacturing, combined with advanced CNC machining capabilities tailored specifically toward OEM/ODM clients’ needs.

Their full-service model spans from CAD support and material selection through to precision machining and surface finishing—including anodizing and powder coating—to deliver turnkey solutions under one roof. With a commitment rooted in innovation and quality control protocols validated by ISO standards, XiHui continues empowering global industries through precision-engineered aluminum solutions delivered at scale.

Summary

OEM/ODM aluminum part services, powered by advanced CNC milling and turning technologies, offer unmatched flexibility across industries—from automation frames to EV chassis components.

Precision machining ensures the tight tolerances necessary for functional integration, while a diverse range of finishing options allows for full customization based on aesthetic or environmental requirements. Choosing an experienced partner like XiHui Aluminium guarantees reliable lead times, a wide selection of profiles and custom tooling options, consistent quality control, and scalable logistics support worldwide.

FAQs

Q1: What is the typical lead time for custom aluminum CNC parts?

A: Lead times vary based on complexity and volume. For parts made from stock material, orders can often be ready to ship within 3-5 days. Custom extrusions requiring new tooling may take an additional 7-15 days. Full container orders typically require 25-30 days for production.

Q2: Can I request specific surface finishes or colors for anodized parts?

A: Yes. Standard finishes include clear (silver) and black anodizing. Custom colors can also be produced upon request, though minimum order quantities (typically 500kg–2000kg) may apply.

Q3: What industries does XiHui Aluminium typically serve?

A: XiHui serves diverse sectors, including industrial automation (frames, supports, and machine bodies), automotive (lightweight structural elements), and consumer electronics (enclosures and display systems), among others requiring precision-engineered aluminum solutions globally.