Innovative aluminum extrusion techniques are transforming sectors. They create lightweight vehicle solutions. They also enable green building designs. This guide highlights the newest breakthroughs revolutionizing material science.

Advancements in Aluminum Extrusion Technology

Aluminum extrusion methods are swiftly advancing. They spark creativity across industries. They enhance precision, productivity, and eco-friendly practices.

Innovations in Extrusion Processes

Aluminum extrusion technology has seen remarkable progress. It changes how materials are managed and applied. Cutting-edge systems now use top-notch equipment. This improves accuracy and efficiency. Swift presses are a major upgrade. They boost production speed. Yet, they preserve quality. Sophisticated cooling setups also play a role. They strengthen the structural traits of extruded aluminum. This ensures steady performance in various uses.

Multi-step extrusion methods have transformed the field. They enable intricate shapes with complex designs. These meet specific project needs. By embracing these forward-thinking techniques, producers create tailored solutions. These address diverse industry demands effectively.

The Role of Automation and Robotics in Aluminum Extrusion

Automation and robotics significantly improve aluminum extrusion tasks. Automated systems simplify production. They cut down on manual work. This reduces mistakes. It also boosts uniformity. Robots take on duties like material handling, die switches, and quality checks.

These technologies enhance productivity. They also increase workplace safety. They limit human contact with risky settings. Automated sorting and packing setups further streamline operations. They ensure accurate product grouping and packaging.

The Impact of Artificial Intelligence on Precision and Efficiency

Artificial intelligence (AI) reshapes aluminum extrusion. It supports smart, data-driven choices. AI tools examine production data instantly. They detect patterns. They also fine-tune settings for peak performance. This cuts material waste. It lowers energy use too.

AI-powered maintenance systems boost equipment reliability. They predict potential issues early. This avoids downtime. It keeps production smooth. As a result, overall output grows substantially.

Emerging Applications of Aluminum Extrusion

Aluminum extrusion versatility reshapes industries. It makes possible lightweight vehicles, renewable energy, and creative architectural solutions.

Lightweight Solutions in the Automotive and Aerospace Sectors

Aluminum extrusion is used more and more in auto and aerospace. It reduces weight. The strength-to-weight ratio is high in aluminum, which is perfect. It reduces vehicle weight without compromising safety or performance. Extruded aluminum parts are used in bodies of cars and aircraft, and structural supports.

It comes after fuel efficiency gains. It also cuts emissions. By replacing heavier materials with aluminum, manufacturers achieve substantial weight savings. They also maintain structural strength.

Increasing Adoption in Renewable Energy Systems

Aluminum extrusion finds growing use in renewable energy applications. Its durability over the long term and corrosion resistance are central. It finds application in solar panel mounts, wind turbine components, and energy storage battery enclosures. These leverage aluminum’s ability to withstand harsh conditions. They offer long-term reliability as well.

With renewable energy on the rise, the need for extruded aluminum increases. This fuels further ingenuity in the sector.

Applications in Modern Architectural Designs

Architects increasingly weave extruded aluminum shapes into contemporary structures. Their flexibility and visual appeal stand out. Aluminum’s ability to form intricate designs inspires creative solutions. These blend utility with aesthetic charm.

Extruded shapes appear in curtain walls, window frames, doors, and building supports. Their lightweight nature simplifies installation. They also provide excellent thermal insulation.

Sustainability and Environmental Considerations

Aluminum extrusion embraces green practices. It focuses on recycling and energy efficiency. These minimize environmental harm sustainably.

Recycling and Circular Economy in Aluminum Extrusion

Recycling is key to aluminum extrusion’s sustainability. Aluminum is fully recyclable. It retains its qualities forever. This makes it essential for circular economy efforts. Recycled aluminum sharply reduces energy use compared to new production.

Producers adopt closed-loop recycling. They reprocess scrap into new goods. This cuts waste. It also saves resources.

Energy-Efficient Production Methods

Energy efficiency drives the aluminum extrusion sector. It aims to shrink its environmental impact. Advanced techniques, like induction heating, reduce energy needs during billet warming.

Improved die designs also help. They enhance material flow during extrusion. This lowers energy use per unit produced.

Reducing Carbon Footprint Through Advanced Technologies

Innovative methods reduce aluminum extrusion’s carbon impact. Renewable energy sources, like solar or wind, power facilities. This offsets emissions from traditional sources.

Process optimization further aids. It boosts efficiency. It also reduces waste. These steps cut greenhouse gas output.

Challenges and Opportunities in the Aluminum Extrusion Industry

Aluminum extrusion fuels progress. Yet, it faces obstacles and possibilities. These shape its future through creativity and market growth.

Addressing Material Limitations with Technological Improvements

Aluminum offers many perks. Still, it’s less robust than metals like steel. Advanced alloys address this. They enhance aluminum’s mechanical traits. They keep its lightweight nature intact.

These advances open new doors. They allow aluminum use in high-strength or durable applications.

Meeting Industry-Specific Requirements and Standards

Each sector has distinct material needs and performance rules. Crafting tailored solutions is tough. Yet, it must stay cost-effective.

Advanced simulation tools assist. They predict how extruded shapes perform under certain conditions. This ensures compliance across industries.

Exploring Global Market Trends and Growth Potential

The global aluminum extrusion market keeps expanding. Demand grows in sectors like automotive, construction, renewable energy, aerospace, electronics, and packaging. Emerging markets offer vast potential. Urbanization and infrastructure growth drive this. Rising spending on durable goods also contributes.

XiHui Aluminium: A Reliable Partner for Aluminum Solutions

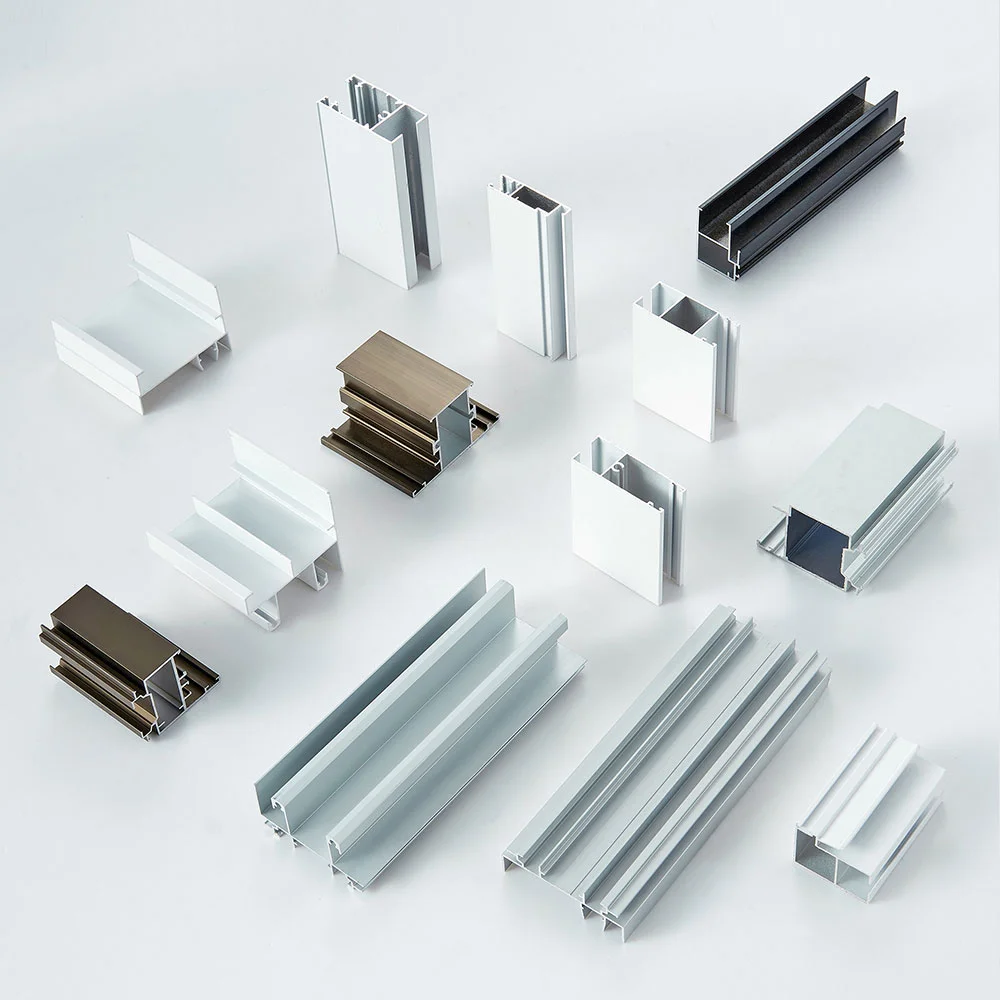

XiHui Aluminium shines in the extrusion industry. They provide a broad range of products and services. These suit various sectors. Their skill lies in crafting top-quality aluminum shapes. These are used in window and door frames, structural parts, and architectural designs. The shapes come in finishes like powder-coated white, black, anodized silver, and electrophoresis champagne. These ensure visual charm and durability.

Their production capacity is strong. For instance, 40HQ containers hold pieces 5.99 meters long. Total weights range from 19-21 tons. Meanwhile, 20GP containers fit 5.8-meter pieces. These weigh 9-10 tons. This adaptability meets clients’ logistical needs.

XiHui Aluminium also offers ODM & OEM services. They provide customized solutions. From manufacturing to packaging and shipping, they make it efficient. That helps wholesalers, producers, and contractors. Accessories like handles, corner joints, door locks, hinges, latches, sliding rollers, and silicone sealants enhance their forms. These offer complete solutions.

Conclusion

XiHui Aluminium embodies dependability in extrusion solutions. They achieve excellence, innovation, and greenness. They have a broad portfolio and tailor-made solutions that make them become a preferred partner. They supply the construction, automotive, aeronautics, renewable energies, and architecture markets. By embracing advanced technology and green practices, they drive industry success.

FAQs on Aluminum Extrusion Technology and Applications

What are the most significant benefits of aluminum extrusion in industrial applications?

Aluminum extrusion has numerous benefits. It is lightweight. It possesses an excellent strength-to-weight ratio. It is resistant to rust. It’s also versatile. All these properties are ideal for automotive, aerospace, and construction industries. Weight reduction and simultaneous durability are crucial here. Extruded shapes can form intricate designs. These meet specific needs. They enhance function and beauty across uses.

How is sustainability being addressed in aluminum extrusion processes?

Sustainability relies on recycling and efficient production. Aluminum is fully recyclable. It keeps its qualities. This reduces reliance on new production. Advanced techniques like induction heating save energy. Closed-loop recycling cuts waste. It also saves resources. These efforts align with global eco-friendly goals.

What industries are expected to see significant growth in aluminum extrusion applications?

Sectors like automotive, aerospace, renewable energy, architecture, electronics, and packaging will grow. Lightweight, durable parts meet rising demands. For example, solar panel frames and wind turbine parts use aluminum’s toughness. Modern building designs incorporate shapes for function and charm.