The quick changes in modular industrial design have sparked a rising need for flexible, light, and tough building materials. Among them, aluminum industrial profiles—extruded aluminum alloys with adjustable cross-sections—serve as basic parts in areas like automation, robotics, and machinery uses. Their importance grows even more when they go through CNC machining methods. These methods help achieve close tolerances and complex shapes. The call for exact, made-to-order CNC machined aluminum profiles built for key performance areas in industries keeps going up.

What Makes Aluminum Profiles Essential in Modular Industrial Systems?

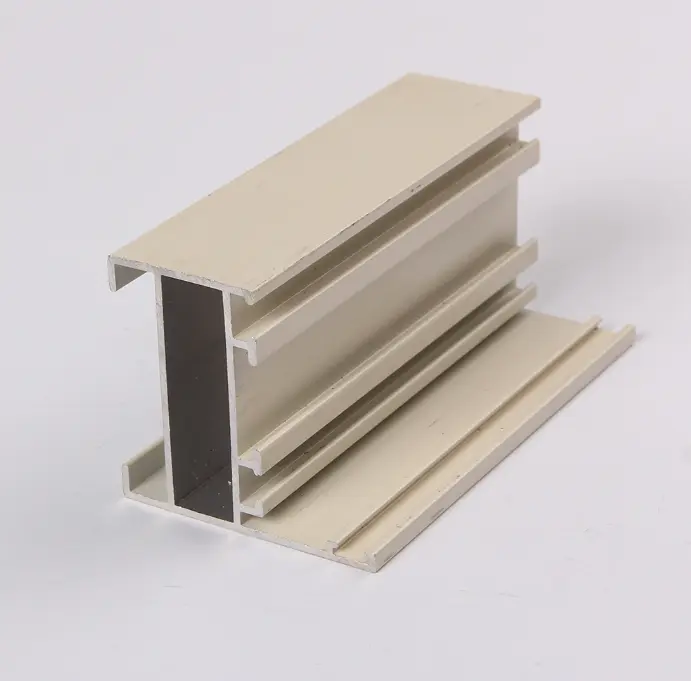

Aluminum’s basic traits give a strong mix of weight, power, and rust protection. Industrial aluminum profiles are alloy materials primarily composed of aluminum, formed by hot melting and extruding aluminum billets to obtain aluminum materials with different cross-sectional shapes. This setup makes it very useful for building frames. At the same time, it lightens the demands on weight support. Plus, its good heat flow helps a lot in setups that need solid cooling, like LED lighting, electronic boxes, and power gear. On top of that, aluminum’s built-in rust shield keeps it lasting long, right in tough factory spots. In short, these features let builders create solid structures that handle daily wear without adding extra bulk or worry about quick breakdown.

How Do Structural Designs Like T-Slots Enhance Modular Flexibility?

T-slot aluminum profiles come with slots that take standard links and bolts. Aluminum profiles for pipelines come in square and rectangular cross-sections, and almost all industrial aluminum profiles have the following characteristics: square, symmetrical, with grooves on all four sides, and a central core in the middle. This setup makes putting together and taking apart much easier. Therefore, it works great for changeable holders, testing tables, safety barriers, and machine bases. Beyond that, the design allows for quick tweaks as needs change. These profiles match well with auto parts such as sensors, movers, and sight tools. That match lets them fit fast into smart factory lines. In turn, it backs up industry 4.0 goals. Overall, such easy linking speeds up work and cuts stop times in active plants.

How Does Standardization Drive Efficiency Across Systems?

Basic aluminum profiles cut down on confusion. They do this by giving steady connection points over different machines and arrangements. By using The overall dimensions of the profile are standard market sizes, but the hole dimensions within the profile are key to assembly. Planners can cut back on repeat designs. They also make upkeep and swap-outs simpler. This flexible style fits right into lean making ideas. It does so by cutting trash and speeding up rollout time.

How Does CNC Machining Elevate Custom Aluminum Solutions?

Modern CNC tools—like 5-axis milling, turning, drilling, and tapping—hit tiny measurement levels. CNC Machining, CNC Milling and Turning, Laser Cutting,Drilling, Grinding, Bending, Stamping, Welding and so on let makers form detailed cuts, edges, openings, and link shapes. They keep things consistent even when making lots of items. No matter if it’s a first test model or growing to many pieces, these steps hold true sizes. At the same time, they lower the need for extra fixes later. In fact, the tech guides cuts with computer help, so each part comes out just like the plan, and that reliability builds trust in high-stakes jobs.

How Are Creative Concepts Turned Into Functional Aluminum Components?

Customers start jobs by sending CAD drawings or real samples. Then, experts check if it’s easy to build and tweak the plan to fit. Using virtual copies and DFM checks makes sure the end piece stays close to the first idea. Yet, it also keeps costs low for making. This support makes working together smooth in early steps. Further, early talks spot fixes before big runs, so the final output works well and stays within plans for time and budget.

What Customization Options Are Available for Industry-Specific Demands?

Different coatings make sure the end item hits both work and look needs:

Anodizing boosts rust block and style draw.

Sandblasting smooths out surface feel and sets up for later layers.

Powder coating gives hue choices with extra rub-proofing.

These layers back uses from health tools to top electronics. They add shields that fight off damage in rough spots. Plus, they can blend with brand looks for items that need to seem pro. In the end, picking the best one shapes the profile to fit just right, be it for hard use or clean show.

Which Industries Benefit Most from Customized Profiles?

- Aerospace: Light but firm frames and covers.

- Automotive: Motor holders, battery boxes, and crash-safe braces.

- Electronics: Heat-shedding shells with EMI guard for key parts.

How Does This Manufacturer Deliver Excellence in Custom Aluminum Profiles?

Look into the build power of this leading CNC aluminum profile supplier. XiHui Aluminium pulls together over 40 CNC work lines, including 5-axis ones. Their shop floor has top tools that reach ±0.01mm exactness. Trained workers watch the full flow—from squeeze to cut—making sure good work at each part. This full watch means steady output that meets tough checks, and it helps handle big orders without slip-ups.

How Are Client Requirements Translated Into Tailored Solutions?

Each job kicks off with close tech talks. The company offers customizable in size and color; size: mold made according to customer drawings; color: customizable oxidation, spraying, wood grain, and various colors. Small run new ideas get help with bendy low order amounts (from 500kg). This gives buyers quick moves in research without big buys. Talks lead to smart changes that boost the end fit. Thus, folks get items that match their wants and often improve their own plans with pro tips.

How Is Quality Controlled Across the Full Production Lifecycle?

Inside check groups use CMMs and shape tools to look at every size and outer layer. ISO 9001-certified steps make sure size truth and outer strength at all points. This steady way brings high buyer joy and less fix work in last put-together. Checks happen often, from start stuff to end pack, so issues pop up early. Because of that, sends reach safe and set for use, growing faith with world partners.

Why Do Global Clients Choose This Manufacturer as a Long-Term Partner?

With more than thirty years helping buyers in over 120 lands, this maker holds strong know-how in spots like auto gear, air frames, health boxes, and robot builds. Their quick make style lets them shift fast to new market pulls. Long time with varied jobs sharpens their touch for hard tasks. Also, their chat focus keeps ties firm, changing single buys into steady works.

What CNC Machining Services Are Offered in Their Portfolio?

Core Services Include:

- Turning for cylindrical features

- Milling for pockets, slots, and contours

- Drilling for precision-mounted holes

Additional Capabilities Cover:

- Tapping internal threads

- Chamfering edges for safety or mating fit

These services let buyers get almost-done items right from the tool. Mixing them builds full sets that need little more work. That saves time and stuff later on. In many cases, it cuts steps for end users, making whole chains smoother.

Which Surface Treatments Can Be Applied to Meet Design Goals?

Common Finishes Include:

- Clear or colored anodizing

- Matte sandblasting

- Powder coating for abrasion resistance

These coats give shield and eye catch in buyer-seen or key-task places. They turn plain items into smooth ones that take daily hits while staying nice. That’s big for marks and long life. Choices let makers match needs, from tough hides to bright shows, keeping all sides happy.

How Is Each Customer’s Project Managed from Start to Finish?

Buyers get quick price bids in 24–48 hours from tech sketches or piece plans. The group does DFM looks first to trim hard parts while keeping work right. From idea to end, steps flow steady with shares to keep all on track. This way turns thoughts to real things fast, with few shocks. Prototyping can be completed in as little as 7–10 days depending on part geometry and finishing needs. Short times mean quick tests, and that helps spot tweaks early before full go.

What Post-Sales Services Ensure Customer Satisfaction?

Set project leads handle all talks. Every buy comes with check papers and track notes. If specs miss rare times, fix or back steps start right away. Help goes past send, with tips on set-up or boosts if needed. So, buyers feel backed all way, leading to more buys and good word spreads.

Summary

Aluminum profiles give top bend for modular setup plans thanks to their power-to-weight mix and fit with basic parts. When boosted by CNC machining services that hit ±0.01mm holds using air-grade mixes like 6061 or 7075, these profiles turn key helpers in today’s trade. They back fast tests to big runs, shifting to what comes up. From small ideas to wide use, they keep things moving smooth in tough spots. With a solid past in world trades and a promise to full check control—this trusted supplier blends tech skill with quick buyer help to bring top aluminum profile fixes at big scale. Their way mixes know with care, making sure each job ends strong and sets up for more wins ahead.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC-machined aluminum profiles?

A1: The MOQ varies depending on complexity but typically starts at 500 kg per model; multiple models totaling over 1 ton are acceptable even if one model is only 500 kg.

Q2: What surface finishing options are available for CNC-machined aluminum profiles?

A2: Available options include anodizing (clear/colored), sandblasting (matte), powder coating (custom colors), brushing, polishing, and electrophoresis.

Q3: Do you support structured data markup to improve SEO visibility?

A3: Yes. Product pages incorporate structured data including Product Schema and FAQ Schema to enhance visibility via rich snippets in search engines.