The market for aluminum extrusion has seen a big increase, fueled by its great strength-to-weight balance, rust resistance, and ability to fit into tricky shapes. Sectors like aerospace, automotive, electronics, and industrial automation have taken up CNC-machined aluminum profiles for key tasks. This holds especially true in areas where cutting weight, keeping structures steady, and exact fitting matter most.

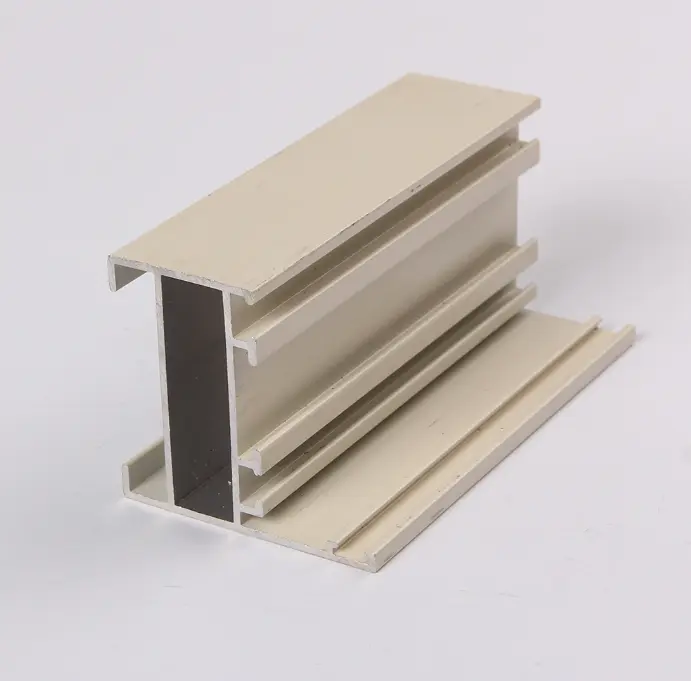

The growing call for industrial aluminum extrusion profiles, such as T-slot, 6060/8080/9090 series, and made-to-order frame setups, shows the rising demand for custom mechanical setups. CNC machining boosts this worth by giving tolerances of ±0.01 mm and allowing detailed shapes that plain extrusion can’t reach on its own.

Why is temperature consistency essential in aluminum extrusion?

Even heat during aluminum extrusion shapes both big and small results in clear ways. Uneven heat spreads can cause size changes, leading to bends, uneven wall sizes, or surface issues like rips and folds. Such uneven spots hurt the exact fit and overall work of the end parts.

For steady results from one batch to the next, extrusion machines need strict heat checks on both the billet and the die. Higher heat lowers the billet’s push-back, but too much can spark surface rips or shape twists, especially when die or billet heat levels don’t match up.

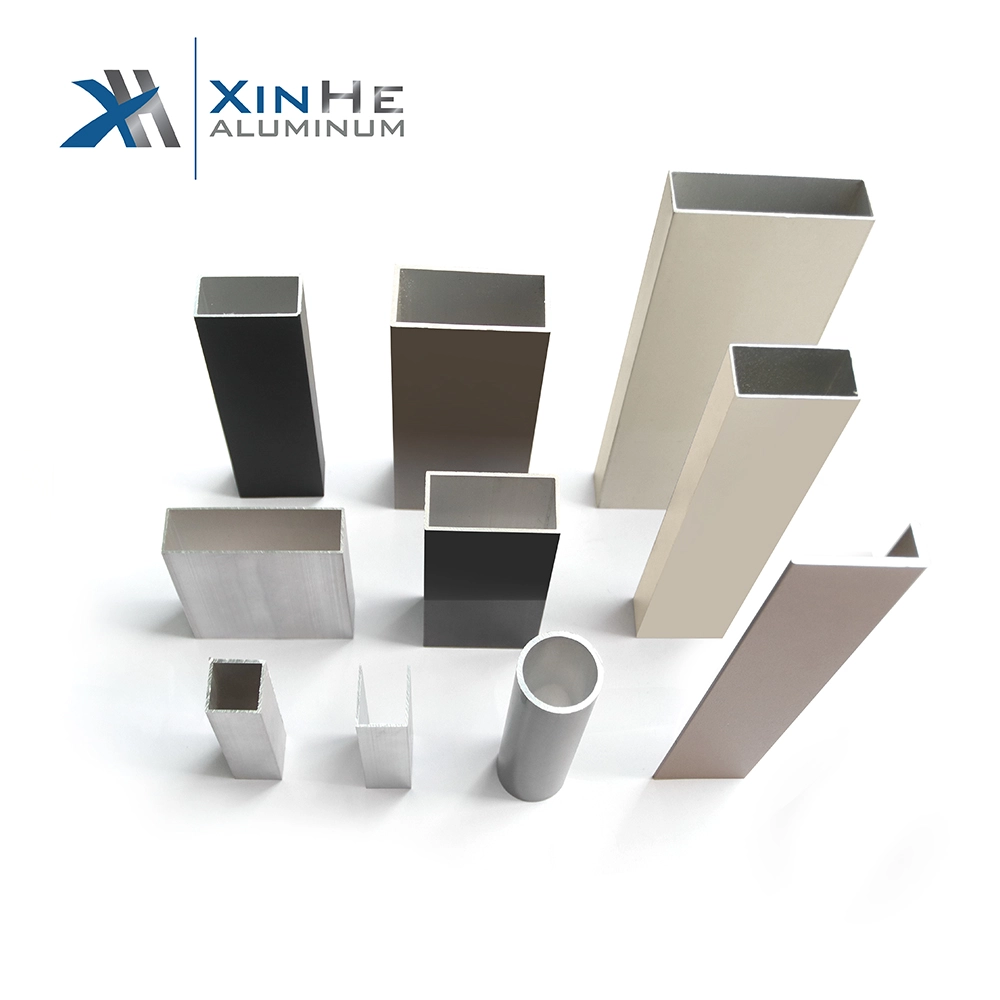

XiHui Aluminium: Precision Customization with CNC Technology

XiHui Aluminium provides exact custom CNC-machined aluminum profiles built for high-stakes fields. By blending CAD/CAM software, skilled engineers’ checks, and adaptable tool arrangements, they turn rough ideas or real samples into ready-for-use parts. Moreover, their setup ensures smooth shifts from early tests to large runs.

From quick prototypes to full output, their CNC skills—which cover 5-axis work, drilling, turning, milling, and laser cuts—back a broad range of uses in areas like medical tools, car parts, and control systems. This wide support helps meet varied needs across industries.

What makes XiHui Aluminium a leading manufacturer of aluminum profiles?

With more than 40 deep-processing units and a yearly output of over 20,000 tons, the plant handles very slim parts and tough shape designs. Their engineering group excels in path tweaks and shape check confirmations using top measurement gear like CMMs. In addition, this setup allows for reliable handling of detailed jobs.

How does XiHui ensure customization precision?

Custom work starts from just 500 kg per plan. They offer free sketch help and fresh mold builds in under 7 days. Working with aluminum types like 6061, 6063, 7075 in T5/T6 states, they hit strict buyer rules for strength work and look finishes. Furthermore, this approach guarantees parts fit exact needs.

What quality control protocols are followed?

Every step in making gets size checks through laser outlines and eye-based surface ranks. Strength tests (pull power, stretch) link to each item’s heat past, making sure not just the sizes but also lasting work trust. As a result, clients get dependable outcomes every time.

How diverse is the company’s industrial experience?

Their history covers over 120 nations, with job setups in aerospace builds, cooling sink units, electronic cases, and cabinet shapes. This worldwide reach confirms they follow different certification needs and material rules. Overall, it builds a strong base for global trust. Explore their advanced capabilities through this featured product: Metal Casting.

The Role of Temperature in the Aluminum Extrusion Process

Spotty heating brings uneven metal movement over the die area, which sparks twists or gaps in filling tough profile spaces. While hotter billets cut down inside push during extrusion, too much warmth can start rips or lines near die outs. Consequently, careful balance proves key to smooth runs.

Why must billet and die temperatures be synchronized?

The main issue lies in matching billet warm-up and die heat. A gap here makes speed differences across the profile’s span, causing changing wall sizes or uneven strength—key in build parts or frame covers. Therefore, sync helps avoid such problems effectively.

What microstructural changes are driven by thermal variations?

Heat input sets the pace of live re-crystal during shape change. This sets end grain scale and direction in the base, affecting pull strength and bend ease. Wrong heat spreads can lead to big grains or spot stresses that hurt long-use life. In short, steady heat shapes better material traits.

Dimensional Stability Challenges Arising from Thermal Fluctuations

Fast or spotty cooling sparks different shrinks in thick against thin profile parts. The inner strains show as turns or curves—needing pricey fixes or toss-outs. This hits harder in uneven plans or large extrusions for control or home uses. Hence, even cooling matters a lot.

How are mechanical tolerances affected by small thermal shifts?

Even tiny changes—±10°C between billet middle and edges—can bring line misfits or off-spec sections. In exact setups like CNC gear frames or LED coolers, this gap blocks later steps like color coating or part joining. Thus, small shifts carry big risks in precision work.

Surface Quality Implications of Temperature Variability

Typical surface flaws include:

- Pick-up marks due to excessive die temperature or frictional heat buildup

- Surface laps from non-uniform metal flow at inconsistent temperatures

- Oxidation or discoloration resulting from overheating during extrusion exit

- These marks not only harm the looks but also block surface adds like color anodizing or dust coating by cutting the stick quality. As such, they demand attention to keep parts top-notch.

How can defects be minimized through better thermal control?

Live infrared watchers placed on the press path track heat swings at vital points. Paired with managed cooling setups (air/water fast cool), they hold steady out heat—cutting after-extrusion bends and boosting surface evenness. This method truly lifts overall quality.

Process Optimization Techniques for Temperature Consistency

Induction warm systems with back loops give spot-on heat power while keeping work speeds up. Staggered billet loads balance the path’s heat weight, cutting start-stop swings over make cycles. Together, these steps ensure smooth, steady production flows.

Can extrusion speed be adjusted dynamically based on temperature?

Yes—new presses use smart control codes that tweak ram pace against live die push, and billet heart reads. This skips overheat in still spots while holding the best pressure spread over tough profiles. In effect, it fine-tunes the whole process for better results.

Quality Control Measures Related to Thermal Management

Infrared heat sensors tied to SCADA setups make ahead warnings when limits pass safe lines—letting workers step in before flaw spread happens. This watch keeps things on track during runs.

What post-extrusion evaluations validate thermal performance?

Key metrics include:

- Laser-based dimensional conformity scans

- Profilometry for surface finish grading

- Mechanical tests mapped against recorded billet/die temperature logs

- These checks let trace the flaw roots to exact heat moments, aiding ongoing step improvements. By linking data this way, improvements come faster and more reliably.

If you seek consistent quality in custom aluminum profiles

Temperature control stands as basic, not extra—it’s core. Makers who skip it face size slips, weak looks, and hurt build work. That’s why teaming with skilled providers who mix CNC + extrusion + heat handling in one spot turns vital. Find out what this mix offers at Custom Industrial 5 Axis CNC Milling Turning Aluminum.

FAQ

Q1: What is the minimum order quantity (MOQ) for custom CNC-machined aluminum parts?

A1: XiHui Aluminium typically supports a flexible MOQ starting from as low as 10 pieces, depending on part complexity and processing requirements.

Q2: What surface treatment options are available for CNC-machined aluminum?

A2: Available surface finishes include anodizing (clear/color), powder coating, sandblasting, brushing, polishing, electrophoresis coating, and chemical conversion coating.

Q3: Does XiHui Aluminium support structured data markup (Schema) for product listings?

A3: Yes, XiHui Aluminium offers structured data implementation using Schema.org standards to enhance search engine visibility through rich snippets such as product specifications and reviews.